Nissan Qashqai J11. Manual - part 418

ECK-232

< DTC/CIRCUIT DIAGNOSIS >

[K9K]

P0340 CMP SENSOR

NO

>> Repair or replace error-detected parts.

4.

CHECK CMP SENSOR-2

ECK-232, "Component Inspection (Camshaft Position Sensor)"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace error-detected parts.

Component Inspection (Camshaft Position Sensor)

INFOID:0000000010289817

1.

CHECK CAMSHAFT POSITION (CMP) SENSOR

1.

Disconnect CMP sensor harness connector.

2.

Check the resistance between CMP sensor terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace CMP sensor.

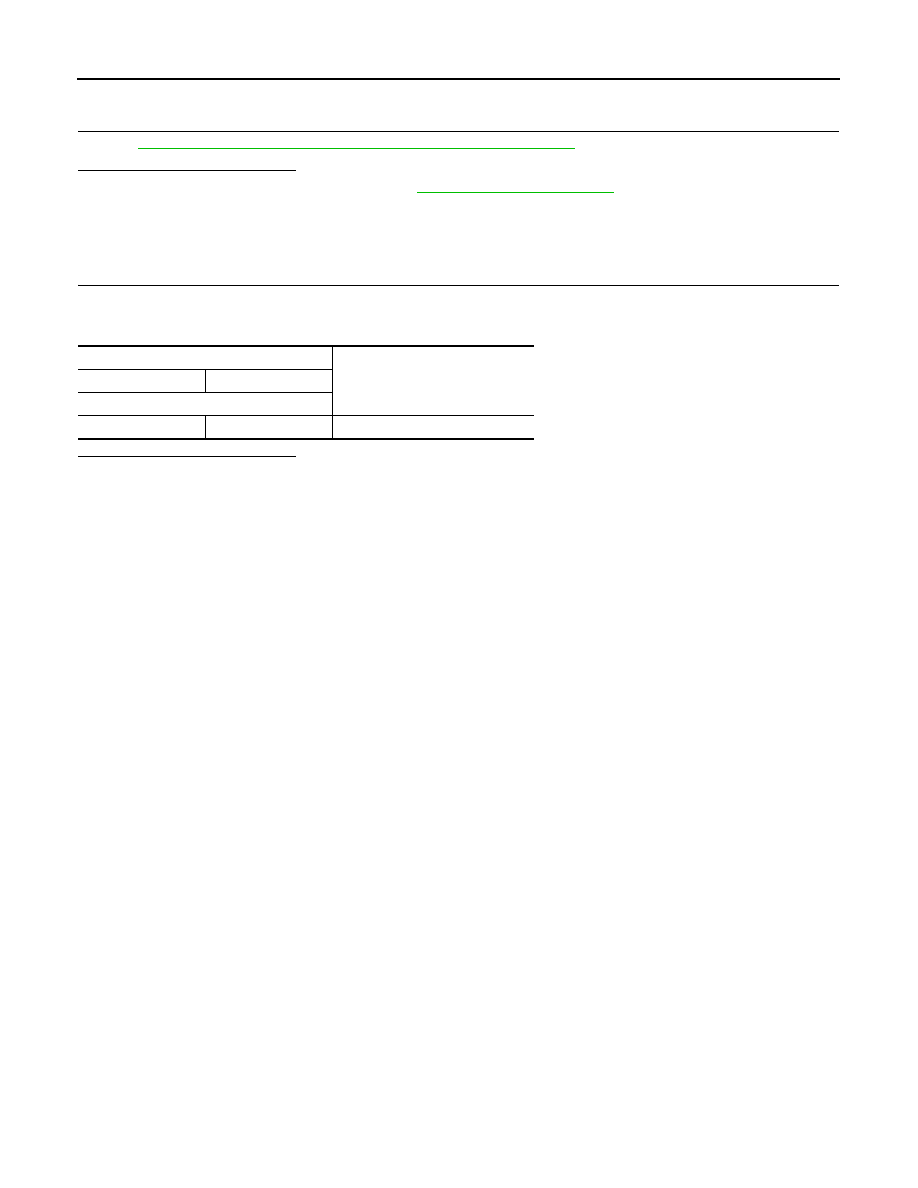

CMP sensor

Resistance

+

-

Terminal

3

2

More than 100 k

Ω