Nissan Qashqai J11. Manual - part 319

P0300, P0301, P0302, P0303, P0304 MISFIRE

ECM-253

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

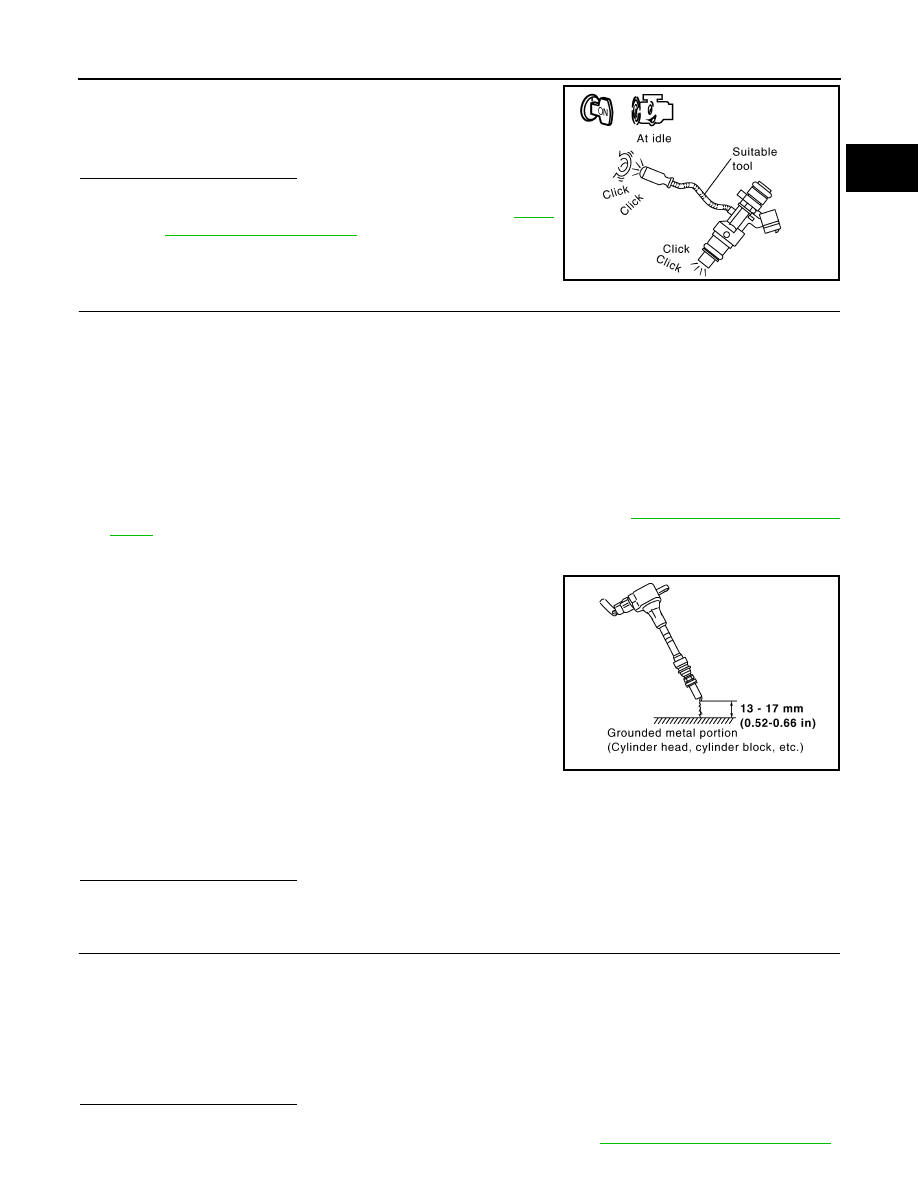

H

I

J

K

L

M

A

ECM

N

P

O

2.

Listen to each fuel injector operation.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Perform trouble diagnosis for fuel injector, refer to

.

5.

CHECK FUNCTION OF IGNITION COIL-1

CAUTION:

Perform the following procedure in a place with no combustible objects and good ventilation.

1.

Turn ignition switch OFF.

2.

Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT to release fuel pressure, or fuel pressure applies again during the following proce-

dure.

3.

Start engine.

4.

After engine stalls, crank it 2 or 3 times to release all fuel pressure.

5.

Turn ignition switch OFF.

6.

Remove all ignition coil harness connectors to avoid the electrical discharge from the ignition coils.

7.

Remove ignition coil and spark plug of the cylinder to be checked. Refer to

.

8.

Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9.

Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 -

0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for approximately 3 seconds, and check whether

spark is generated between the spark plug and the grounded

metal portion.

CAUTION:

• Never place the spark plug and the ignition coil within 50

cm (19.7 in) each other. Be careful not to get an electrical

shock while checking, because the electrical discharge voltage becomes 20 kV or more.

• It might damage the ignition coil if the gap of more than 17 mm (0.66 in) is made.

NOTE:

When the gap is less than 13 mm (0.52 in), a spark might be generated even if the coil is malfunctioning.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> GO TO 6.

6.

CHECK FUNCTION OF IGNITION COIL-2

1.

Turn ignition switch OFF.

2.

Disconnect spark plug and connect a non-malfunctioning spark plug.

3.

Crank engine for approximately 3 seconds, and recheck whether spark is generated between the spark

plug and the grounded metal portion.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Check ignition coil, power transistor and their circuits. Refer to

ECM-385, "Diagnosis Procedure"

.

Clicking sound should

be heard.

PBIB3332E

Spark should be gener-

ated.

JMBIA0066GB

Spark should be gener-

ated.