Nissan Qashqai J11. Manual - part 315

P0172 FUEL INJECTION SYSTEM FUNCTION

ECM-237

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

ECM

N

P

O

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 2.

2.

CHECK FOR INTAKE AIR LEAKAGE

1.

Listen for an intake air leakage after the mass air flow sensor.

2.

Check PCV hose connection.

Is intake air leakage detected?

YES

>> Repair or replace malfunctioning part.

NO

>> GO TO 3.

3.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect corresponding A/F sensor 1 harness connector.

3.

Disconnect ECM harness connector.

4.

Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

5.

Check the continuity between A/F sensor 1 harness connector and ground, or ECM harness connector

and ground.

6.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning part.

4.

CHECK FUEL PRESSURE

1.

Install all removed parts.

2.

Release fuel pressure to 0. Refer to

3.

Set a fuel pressure meter and check fuel pressure. Refer to

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace malfunctioning fuel gauge unit. Refer to

.

5.

CHECK MASS AIR FLOW SENSOR

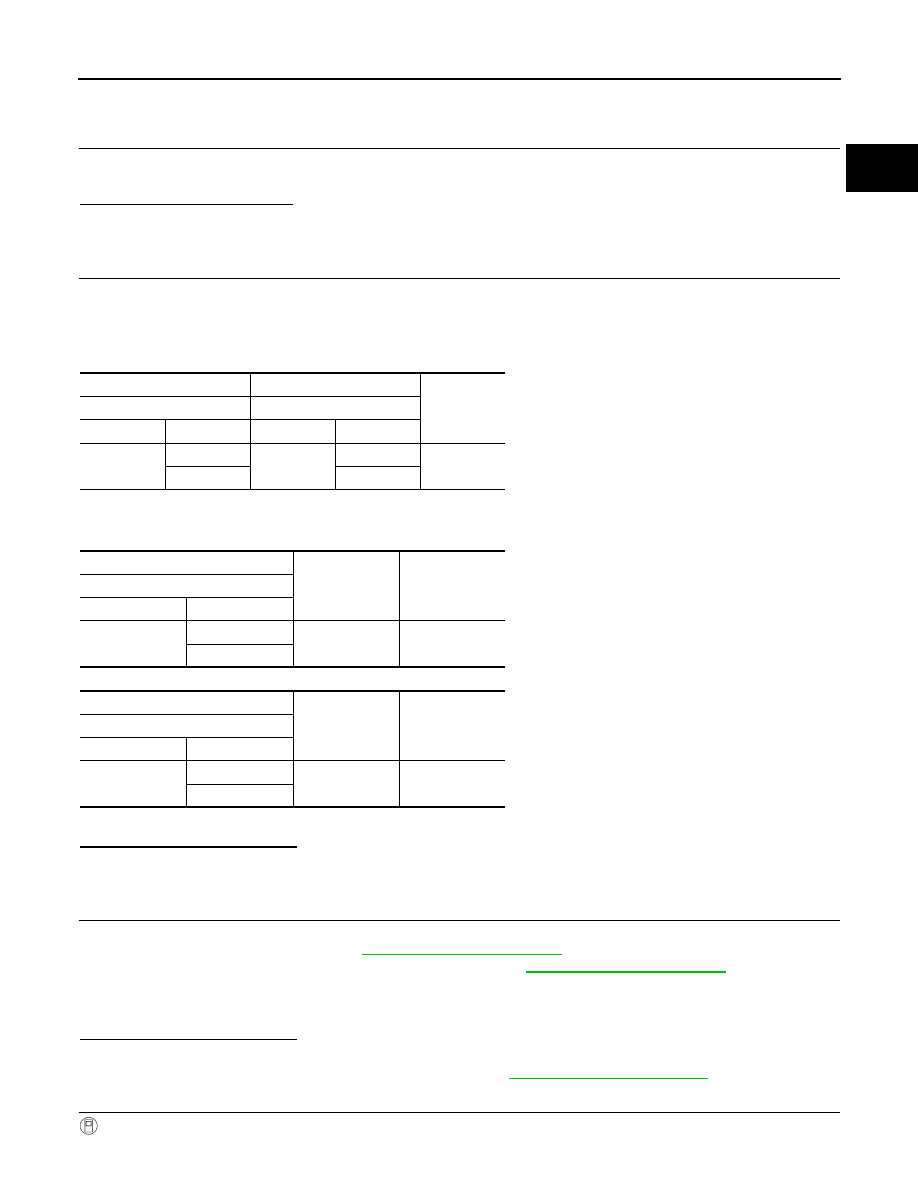

WITH CONSULT

+

−

Continuity

A/F sensor 1

ECM

Connector

Terminal

Connector

Terminal

F74

1

F16

64

Existed

2

72

+

Ground

Continuity

A/F sensor 1

Connector

Terminal

F74

1

Ground

Not existed

2

+

Ground

Continuity

ECM

Connector

Terminal

F16

64

Ground

Not existed

72

At idle: 500 kPa (5.0 bar, 5.1 kg/cm

2

, 73 psi)