Content .. 2264 2265 2266 2267 ..

Nissan Qashqai J11. Manual - part 2266

ENGINE MAINTENANCE (R9M)

MA-99

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

2.

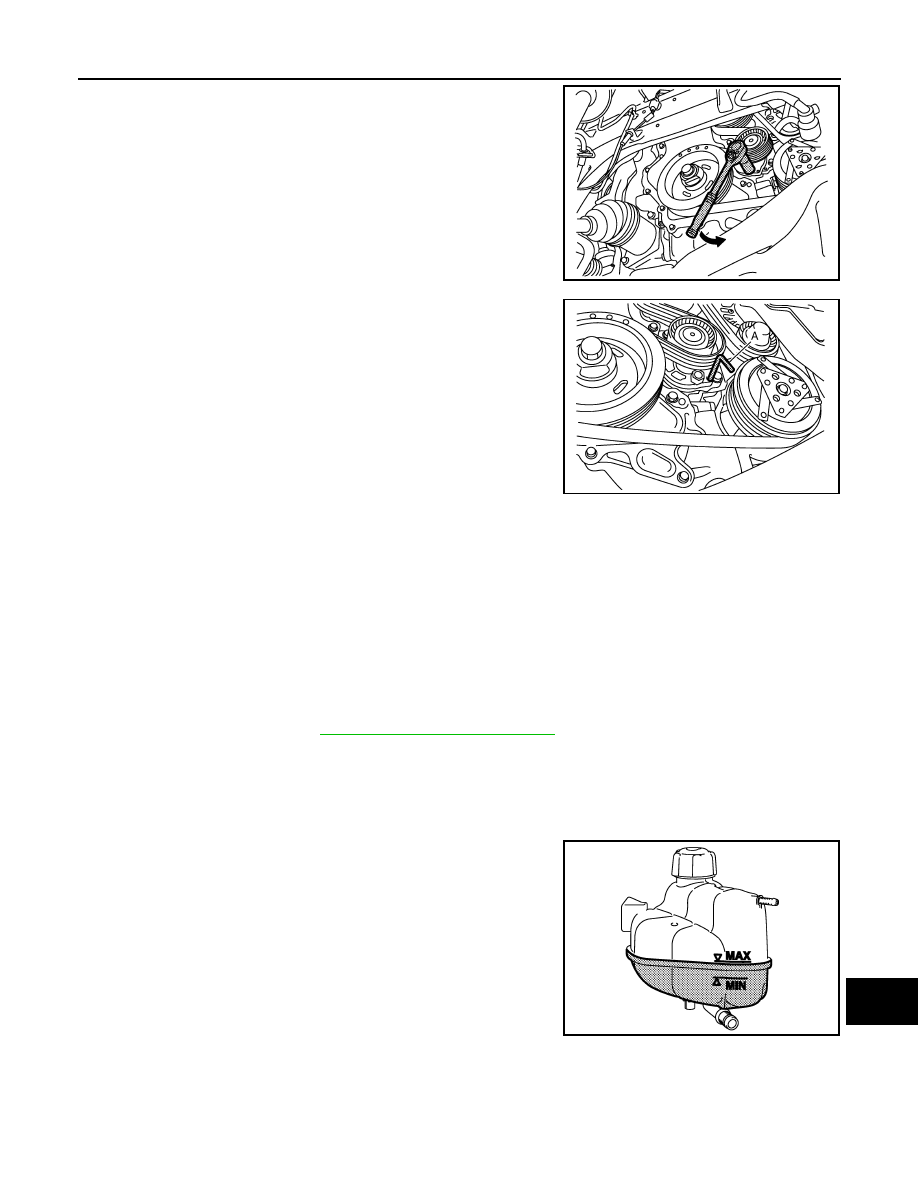

Hold the hexagonal part of drive belt auto-tensioner pulley with a

hexagonal socket (A) securely. Then move the wrench handle in

the direction of arrow (loosening direction of tensioner).

CAUTION:

Never place hand in a location where pinching may occur if

the holding tool accidentally comes off.

3.

Insert a stopper pin (A) in diameter such as short-length screw-

driver into the hole of the retaining boss to fix drive belt auto-ten-

sioner pulley.

• Keep drive belt auto-tensioner pulley arm locked after drive

belt is removed.

NOTE:

Use approximately 3.0 mm (0.118 in) dia. hard metal pin as a

stopper pin.

4.

Remove drive belt.

INSTALLATION

1.

Install drive belt.

CAUTION:

• Check that drive belt is completely set to pulleys.

• Check for engine oil, working fluid and engine coolant are not adhered to drive belt and each

pulley groove.

2.

Release drive belt auto-tensioner, and apply tension to drive belt.

3.

Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

4.

Check that the indicator (notch on fixed side) of drive belt auto-tensioner is within the range when new

drive belt is installed. Refer to

MA-98, "DRIVE BELT : Checking"

.

ENGINE COOLANT

ENGINE COOLANT : Inspection

INFOID:0000000010503164

LEVEL

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” when the engine is cool.

• Adjust the engine coolant level as necessary.

• Check that the reservoir tank cap is tightened.

WARNING:

Never remove reservoir tank cap when engine is hot. Serious

burns could occur from high-pressure engine coolant escaping

from reservoir tank.

LEAKAGE

E1BIA0658ZZ

E1BIA0657ZZ

E1BIA1145ZZ