Content .. 1544 1545 1546 1547 ..

Nissan Qashqai J11. Manual - part 1546

BRM-12

< PRECAUTION >

[FOR EUROPE (LHD)]

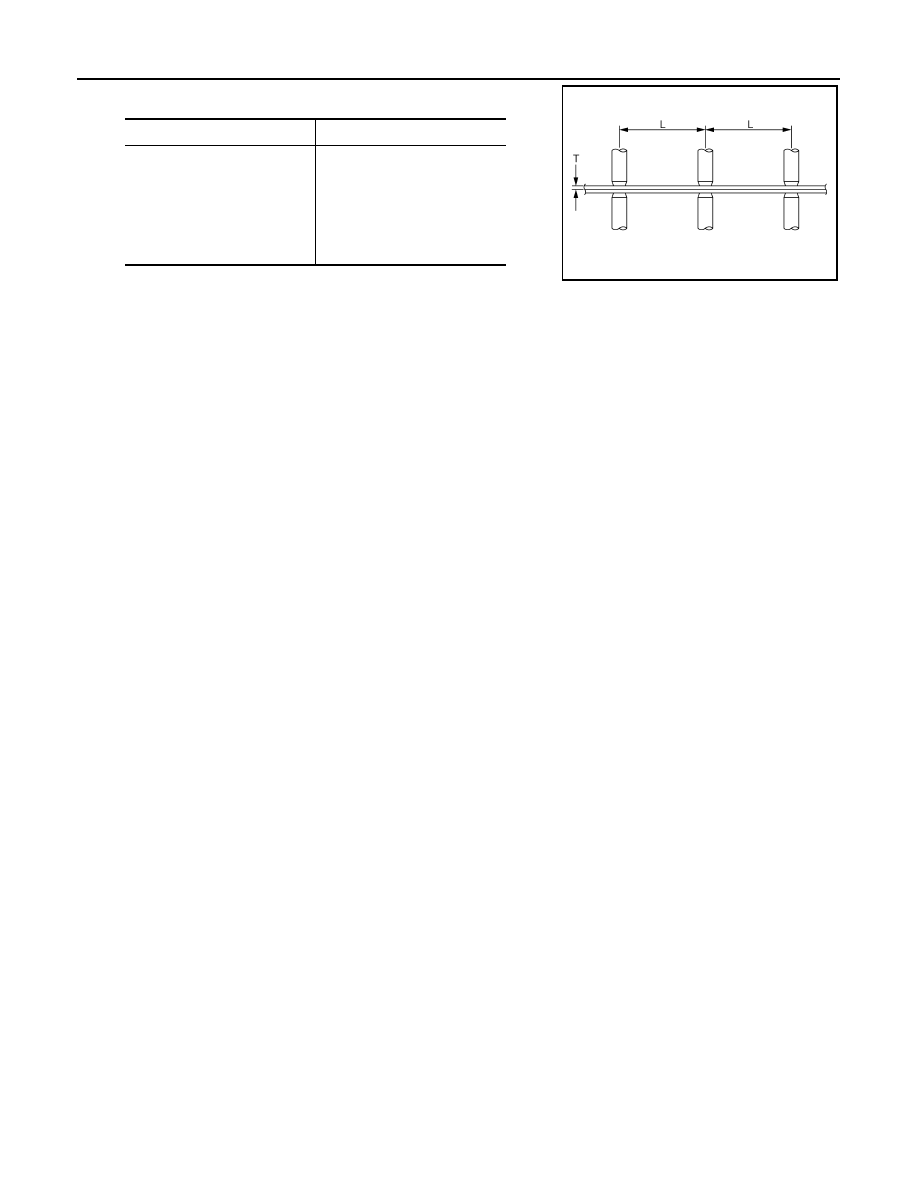

REPAIRING HIGH STRENGTH STEEL

• Follow the specifications for the proper welding pitch.

Unit: mm (in)

Thickness (T)

Minimum pitch (L)

0.6 (0.024)

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.6 (0.063)

1.8 (0.071)

10 (0.39) or more

12 (0.47) or more

18 (0.71) or more

20 (0.79) or more

27 (1.06) or more

31 (1.22) or more

JSKIA0781ZZ