Content .. 1043 1044 1045 1046 ..

Nissan Qashqai J11. Manual - part 1045

HA-6

< HOW TO USE THIS MANUAL >

[TYPE 1]

APPLICATION NOTICE

HOW TO USE THIS MANUAL

APPLICATION NOTICE

Information

INFOID:0000000010709184

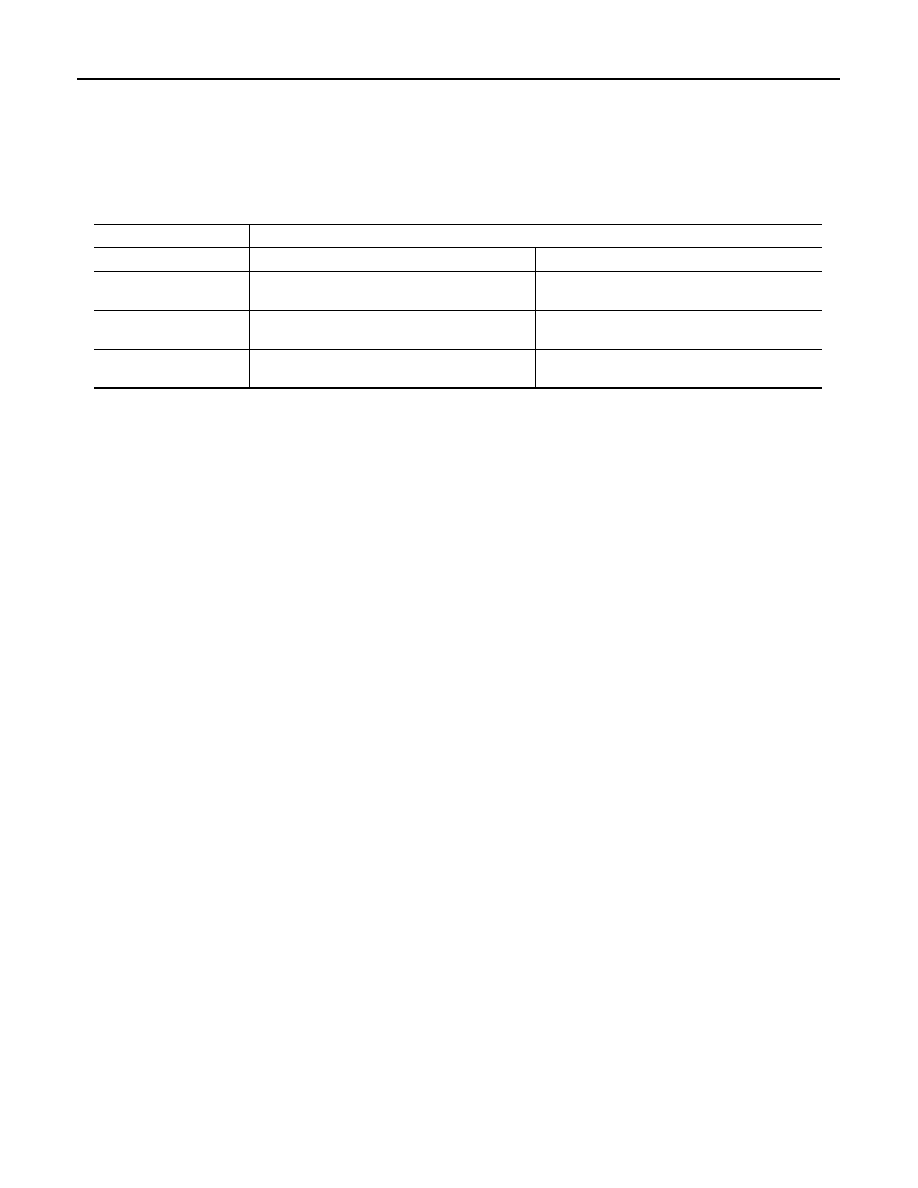

Check the vehicle type to use the service information in this section.

Service information

Destination

Type 1

For Europe

HRA2DDT engine models

Type 2

For Europe

• K9K engine models

• R9M engine models

Type 3

Except for Europe

• HRA2DDT engine models

• MR20DD engine models

Type 4

Except for Europe

• K9K engine models

• R9M engine models