Nissan Qashqai J11. Manual - part 96

CYLINDER HEAD

EM-323

< UNIT DISASSEMBLY AND ASSEMBLY >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

CYLINDER HEAD

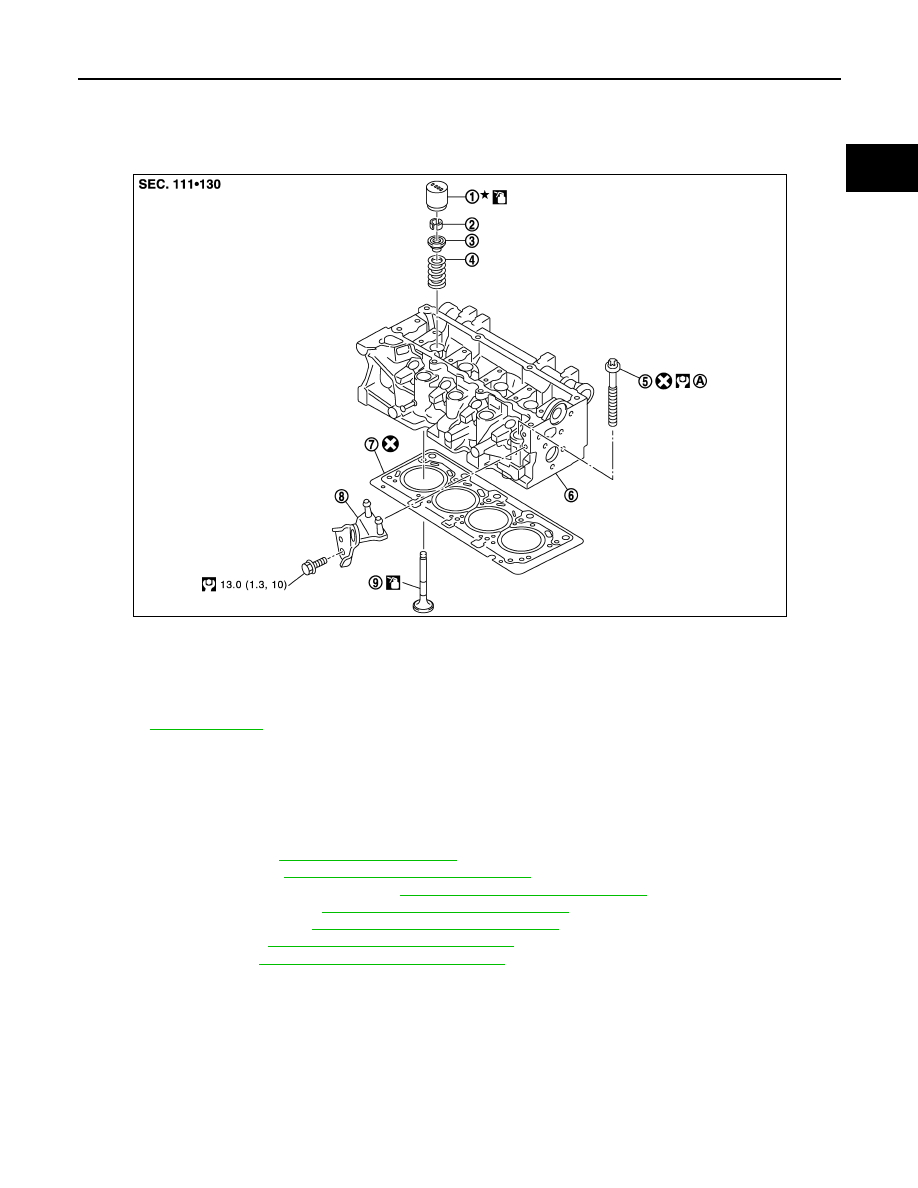

Exploded View

INFOID:0000000010282099

Removal and Installation

INFOID:0000000010282100

REMOVAL

1.

Remove the following parts.

• Engine cover.

• Air inlet tube: Refer to

.

• Rocker cover: Refer to

EM-303, "Removal and Installation"

• Injection tube and fuel injector: Refer to

EM-293, "Removal and Installation"

• High pressure supply pump:

EM-300, "Removal and Installation"

.

• Exhaust manifold: Refer to

EM-289, "Removal and Installation"

• Timing belt: Refer to

EM-305, "Removal and Installation"

.

• Camshaft: Refer to

EM-313, "Removal and Installation"

.

1.

Valve lifter

2.

Valve collet

3.

Valve spring retainer

4.

Valve spring

5.

Cylinder head bolt

6.

Cylinder head

7.

Cylinder head gasket

8.

Engine slinger

9.

Valve

A.

25.0 N·m (2.6 kg-m, 18ft-lb) and 255 degrees

Refer to

E1BIA0024GB