Nissan Qashqai J11. Manual - part 66

CAMSHAFT

EM-203

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

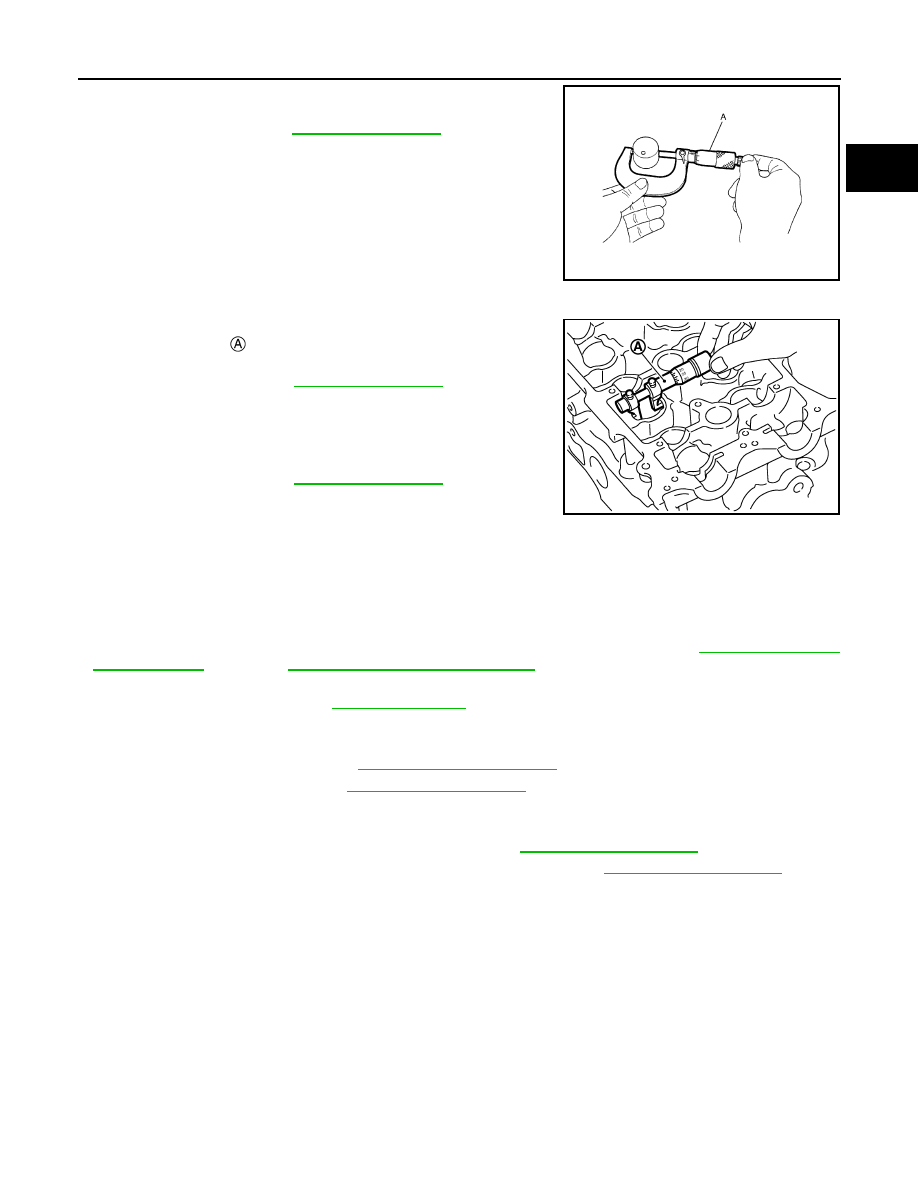

• Measure the outer diameter of valve lifter with a micrometer (A).

VALVE LIFTER HOLE DIAMETER

Measure the inner diameter of valve lifter hole of cylinder head with

an inside micrometer

.

VALVE LIFTER CLEARANCE

• (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter

outer diameter)

• If out of the standard, referring to the each standard of valve lifter

outer diameter and valve lifter hole diameter, replace either or both

valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT), (EXH) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 or P0014 is detected in self-diagnostic results of CON-

SULT and it is directed according to inspection procedure of EC section. Refer to

(P0011) or

ECM-161, "Diagnosis Procedure"

• Check when engine is cold so as to prevent burns by the splashing engine oil.

1.

Check engine oil level. Refer to

2.

Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a.

Release the fuel pressure. Refer to

.

b.

Remove intake manifold. Refer to

c.

Disconnect ignition coil and injector harness connectors.

d.

Support the bottom surface of engine using a transmission jack, and then remove the engine mounting

bracket (RH) and engine mounting insulator (RH). Refer to

.

3.

Remove intake or exhaust valve timing control solenoid valve. Refer to

.

• Lift the front side of the engine with a jack base to remove intake or exhaust valve timing control sole-

noid valve.

4.

Clean the mounting area of intake or exhaust valve timing control solenoid valve, and then insert a clean

waste with no oil adhesion into the oil hole of the cylinder head.

5.

Install engine mounting insulator (RH) and engine mounting bracket (RH). (After the removal of intake or

exhaust valve timing control solenoid valve and insertion of a waste into the oil hole.)

6.

Perform cranking to check that engine oil comes out from the oil hole (mounting hole of intake or exhaust

valve timing control solenoid valve) of cylinder head.

• Regarding the engine oil check, judge it by the amount of oil adhered to the wasted inserted into the oil

hole.

WARNING:

• Never insert fingers into the oil hole.

• Never touch rotating parts (drive belt, idler pulleys and crankshaft pulley, etc.).

CAUTION:

Standard

: Refer to

.

JPBIA0125ZZ

Standard

: Refer to

.

Standard

: Refer to

.

PBIC3184J