Nissan Qashqai J11. Manual - part 42

CYLINDER BLOCK

EM-107

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• Place a dial indicator (A) straight up on the No. 3 journal.

• While rotating crankshaft, read the movement of the pointer on the

dial indicator. (Total indicator reading)

• If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

• Install connecting rod bearings (2) to connecting rod (3) and con-

necting rod bearing cap (1), and tighten connecting rod cap bolts to

the specified torque. Refer to

EM-93, "Disassembly and Assem-

• Measure the inner diameter of connecting rod bearing with an

inside micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter)

– (Crankshaft pin journal diameter)

• If clearance exceeds the limit, select proper connecting rod bearing according to connecting rod big end

diameter and crankshaft pin journal diameter to obtain specified bearing oil clearance. Refer to

.

Method of Using Plastigage

• Remove engine oil and dust on crankshaft pin and the surfaces of each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install connecting rod bearings to connecting rod and cap, and tighten connecting rod cap bolts to the speci-

EM-93, "Disassembly and Assembly"

.

CAUTION:

Never rotate crankshaft.

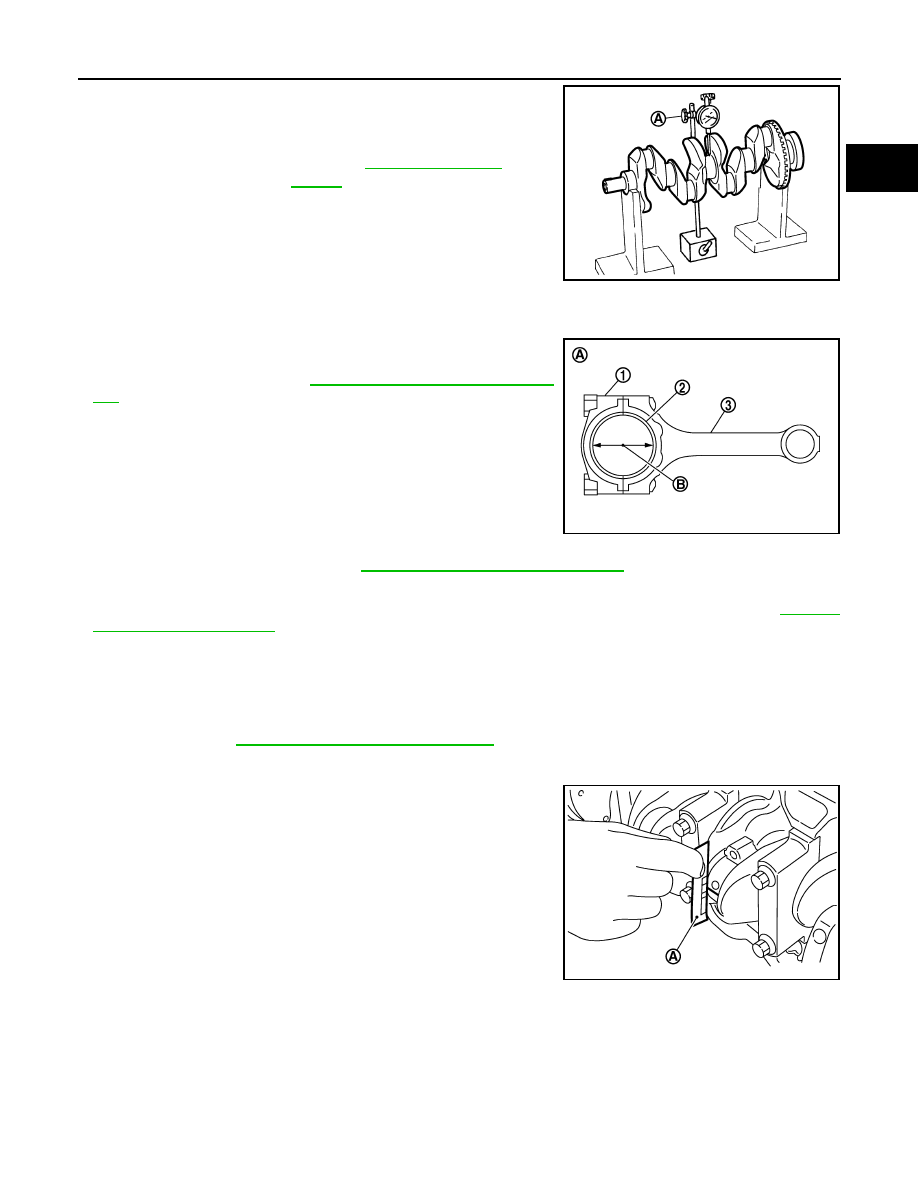

• Remove connecting rod cap and bearing, and using the scale (A)

on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

Standard and Limit

: Refer to

PBIC3458J

A

: Example

B

: Inner diameter measuring direction

Standard and Limit

: Refer to

EM-121, "Connecting Rod Bearing"

PBIC3275J

PBIC3276J