Nissan Qashqai J11. Manual - part 25

HIGH PRESSURE FUEL PUMP AND FUEL HOSE

EM-39

< REMOVAL AND INSTALLATION >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

a.

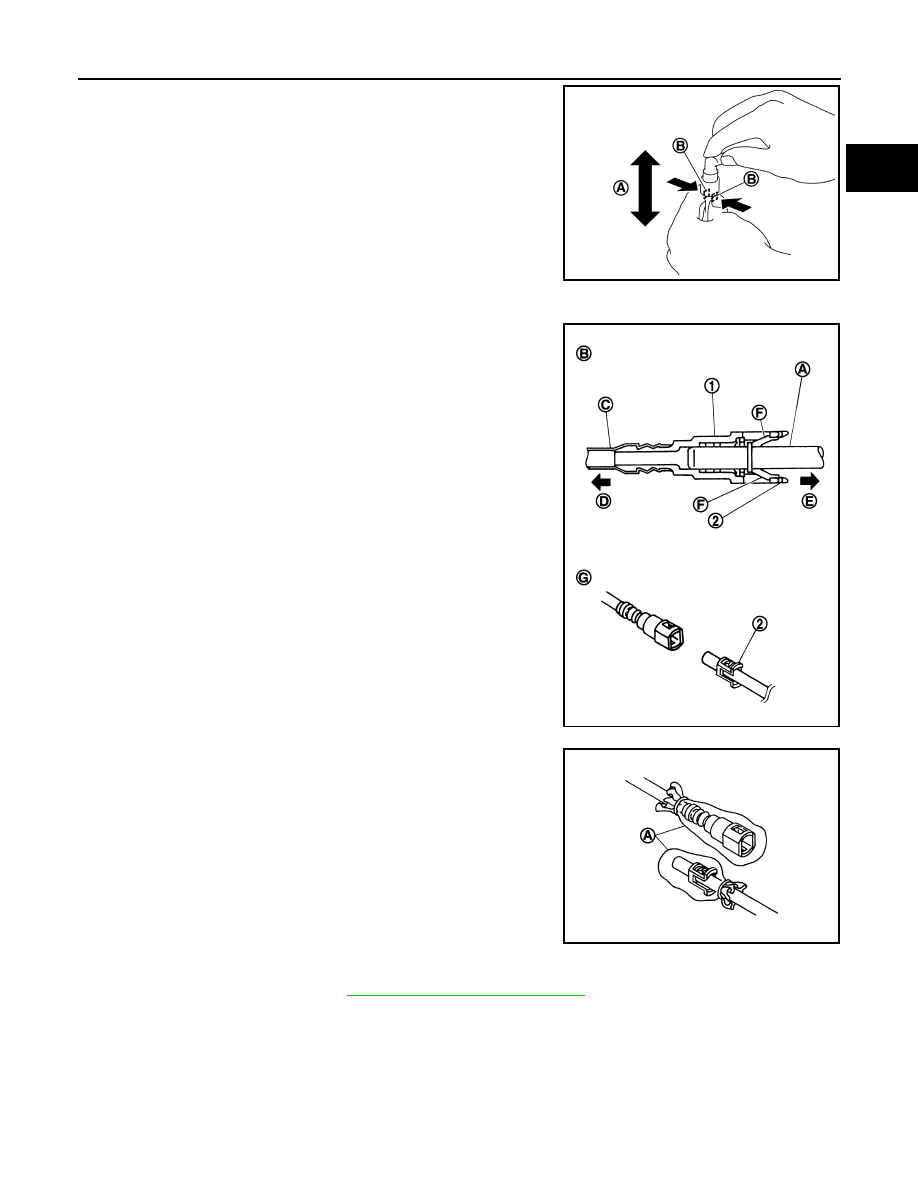

Remove quick connector in the following procedures.

i.

Hold the connector while pushing tabs, and pull out the tube.

ii.

If quick connector sticks to high pressure fuel pump, push and

pull quick connectors several times until they start to move.

Then disconnect them by pulling.

CAUTION:

• Quick connector (1) can be disconnected when the tabs of

retainer (F) are depressed completely. Never twist it more

than necessary.

• Never use any tools to disconnected quick connector.

• Keep resin hose (C) away from heat. Be especially careful

when welding near the resin hose.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Never bend or twist resin tube during installation and dis-

connection.

• Never remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

• To prevent damage to each joint and protect it from the

entry of foreign matter, cover the joint with plastic bag (A)

or an equivalent.

4.

Disconnect high pressure fuel pump connector.

5.

Remove intake manifold. Refer to

EM-25, "Removal and Installation"

6.

Remove high pressure fuel pipe using [SST: KV113E0010 (Mot.1566)].

7.

Remove high pressure fuel pump and lifter.

CAUTION:

To prevent damage to high pressure fuel pump and rocker cover, loosen high pressure fuel pump

bolts alternately by one turn at a time until the reaction force applied on the high pressure fuel

pump disappears.

INSTALLATION

A

: Pull

B

: Push in tabs

JSBIA1689ZZ

B

: Connection (cross-section)

D

: To under floor fuel line

E

: To engine

G

: Disconnection

Retainer color

: Green

JPBIA0130ZZ

JPBIA0135ZZ