Nissan Juke F15. Manual - part 987

MA-40

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

TRANSFER OIL : Refilling

INFOID:0000000012200226

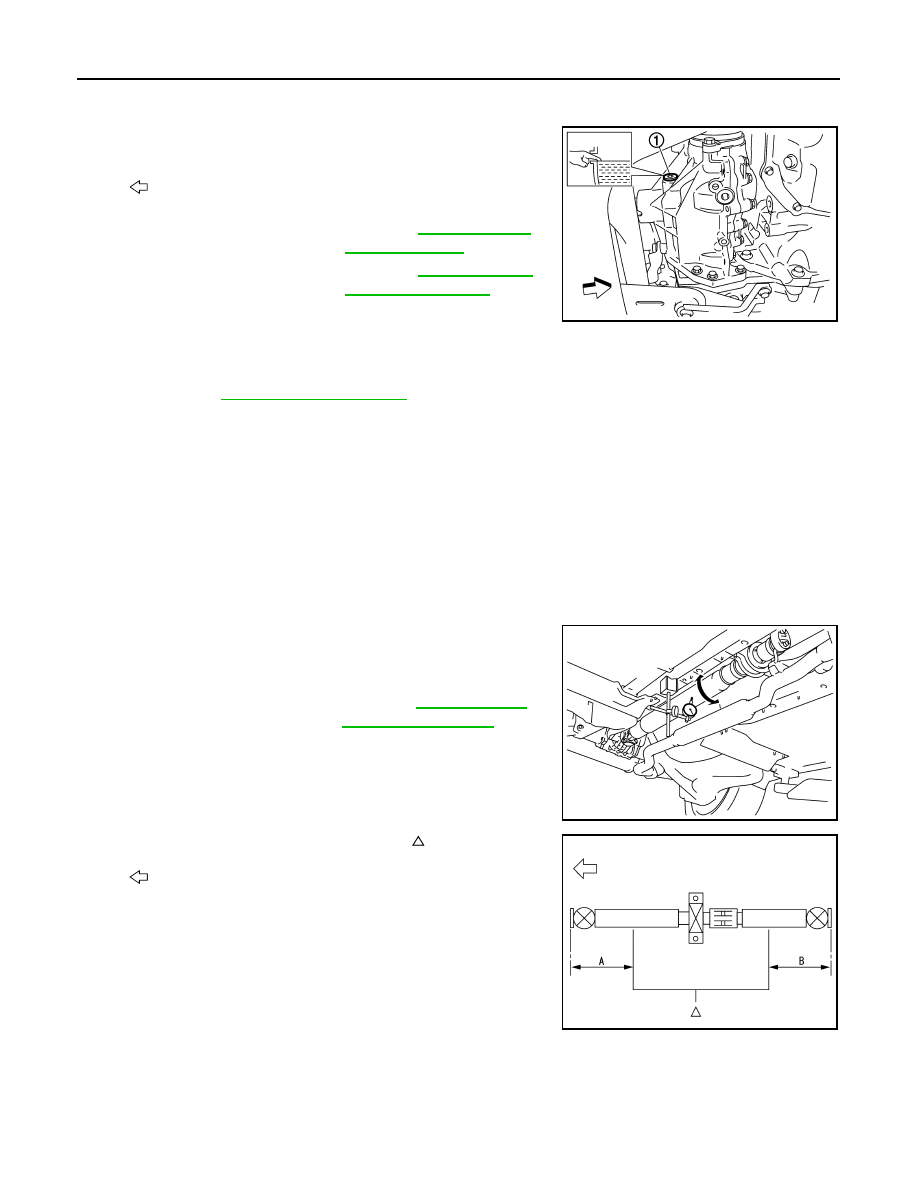

1. Remove filler plug (1) and gasket. Then fill oil up to mounting

hole for the filler plug.

CAUTION:

Carefully fill the oil. (Fill up for approximately 3 minutes.)

2. Leave the vehicle for 3 minutes, and check the oil level again.

3. Before installing filler plug, set a new gasket. Install filler plug on transfer and tighten to the specified

CAUTION:

Never reuse gasket.

REAR PROPELLER SHAFT

REAR PROPELLER SHAFT : Inspection

INFOID:0000000012200227

APPEARANCE AND NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

If vibration is present at high speed, inspect propeller shaft runout first.

1. With a dial indicator, measure propeller shaft runout at runout

measuring points by rotating final drive companion flange with

hands.

• Propeller shaft runout measuring point (Point “ ”)

2. If runout still exceeds specifications, separate propeller shaft at

final drive companion flange or transfer companion flange; then

change the phase between companion flange and propeller

shaft by the one bolt hole at a time and install propeller shaft.

3. Check runout again. If runout still exceeds specifications,

replace propeller shaft assembly.

4. Check the vibration by driving vehicle.

REAR DIFFERENTIAL GEAR OIL

: Vehicle front

Oil and viscosity

: Refer to

.

Oil capacity

: Refer to

.

JSDIA2080ZZ

Propeller shaft runout

: Refer to

.

JPDID0419ZZ

: Front

Dimension

A: 542 mm (21.34 in)

B: 516.5 mm (20.33 in)

JSDIA2286ZZ