Nissan Juke F15. Manual - part 960

LAN

IPDM-E BRANCH LINE CIRCUIT

LAN-177

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 8)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

IPDM-E BRANCH LINE CIRCUIT

Diagnosis Procedure

INFOID:0000000012200643

1.

CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the IPDM E/R for damage, bend and loose connection (unit side

and connector side).

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

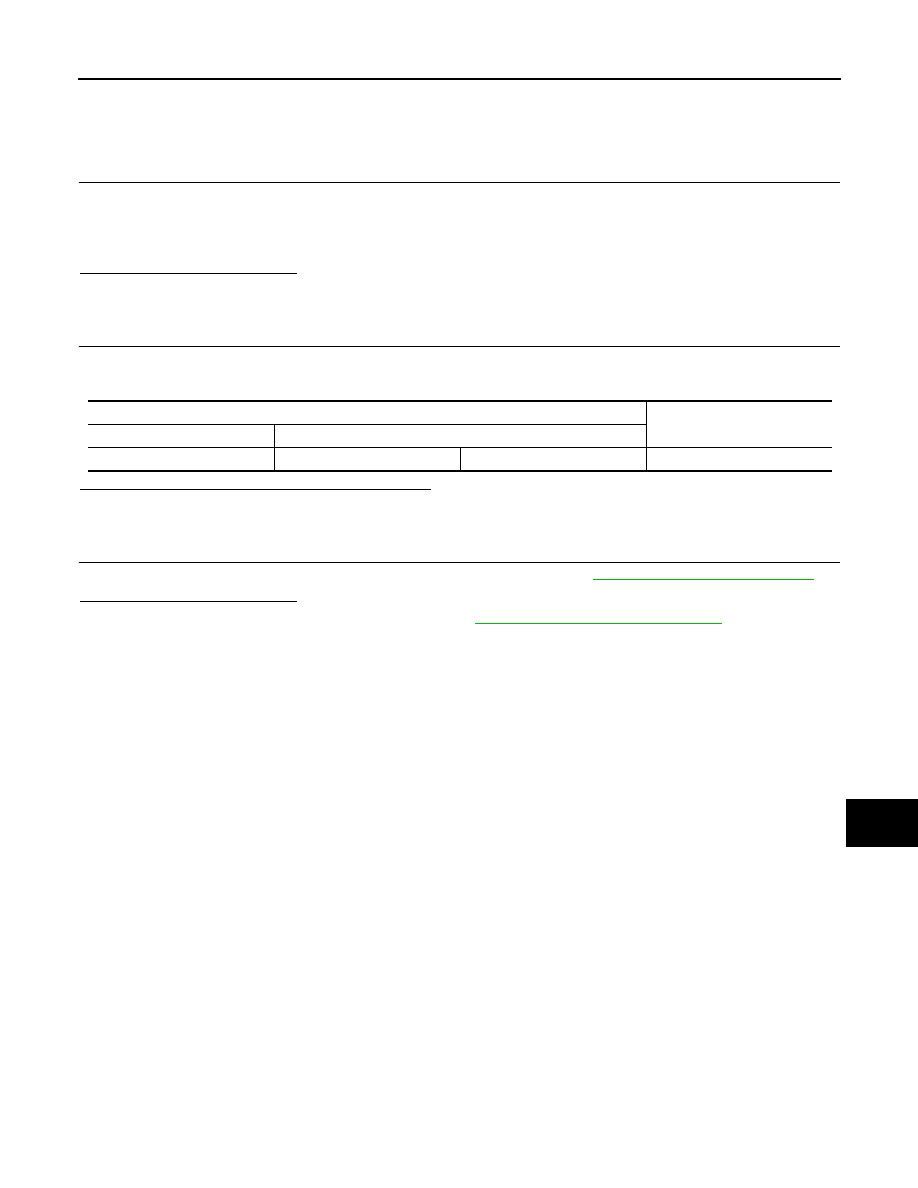

CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of IPDM E/R.

2. Check the resistance between the IPDM E/R harness connector terminals.

Is the measurement value within the specification?

YES

>> GO TO 3.

NO

>> Repair the IPDM E/R branch line.

3.

CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the IPDM E/R. Refer to

Is the inspection result normal?

YES (Present error)>>Replace the IPDM E/R. Refer to

PCS-37, "Removal and Installation"

YES (Past error)>>Error was detected in the IPDM E/R branch line.

NO

>> Repair the power supply and the ground circuit.

IPDM E/R harness connector

Resistance (

Ω)

Connector No.

Terminal No.

E13

27

26

Approx. 54 – 66