Nissan Juke F15. Manual - part 921

LAN

DIAGNOSIS AND REPAIR WORKFLOW

LAN-21

< BASIC INSPECTION >

[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

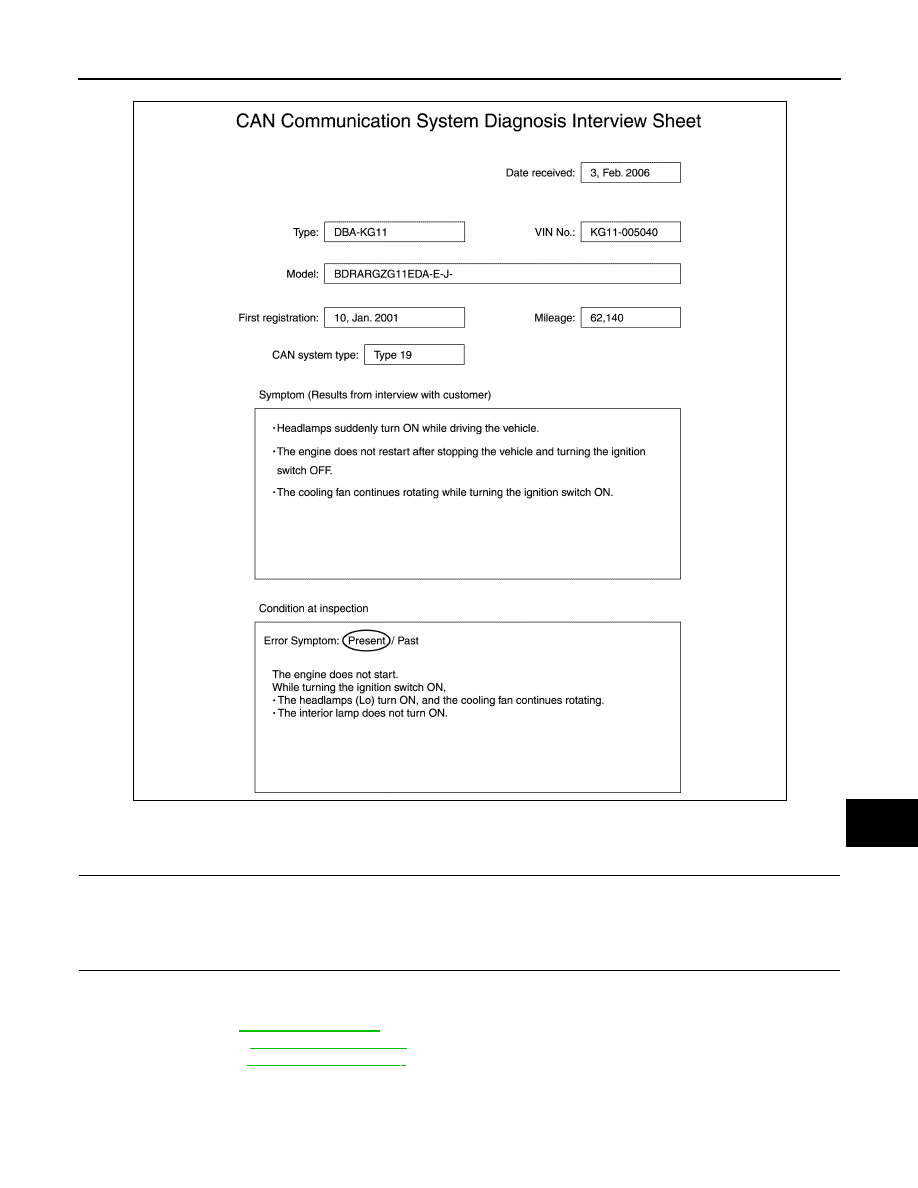

Interview Sheet (Example)

>> GO TO 5.

5.

DETECT THE ROOT CAUSE

CAN diagnosis function of CONSULT detects a root cause.

>> GO TO 6.

6.

REPAIR OR REPLACE MALFUNCTIONING PART

Repair or replace malfunctioning parts identified by CAN diagnosis function of CONSULT.

Maine line>>Refer to

Branch line>> Refer to

Shoort line>> Refer to

.

JSMIA0531GB