Nissan Juke F15. Manual - part 657

EM-182

< BASIC INSPECTION >

[MR EXCEPT FOR NISMO RS MODELS]

COMPRESSION PRESSURE

COMPRESSION PRESSURE

Inspection

INFOID:0000000012197368

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to

3. Remove ignition coil and spark plug from each cylinder. Refer to

4. Connect engine tachometer (not required in use of CONSULT).

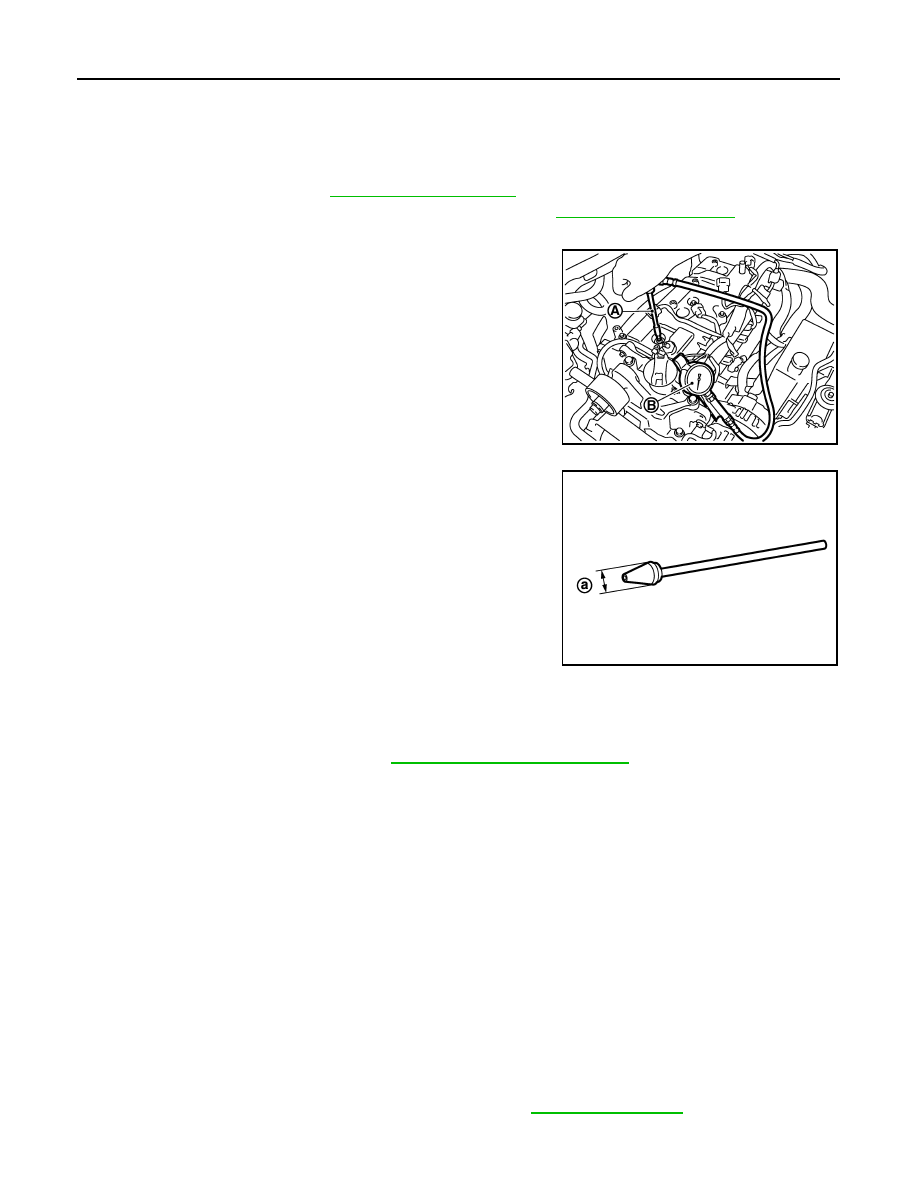

5. Install compression gauge (B) with an adapter (A) (commercial

service tool) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plug

hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it

may be caught by cylinder head during removal.

6. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge

pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each

cylinder.

CAUTION:

Always use a fully charged battery to obtain the specified engine speed.

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances, and parts associated with

combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, and cylinder

head gasket). After the checking, measure compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to recheck it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cyl-

inder head gaskets.

7. After inspection is completed, install removed parts.

8. Start the engine, and check that the engine runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to

PBIC3541J

a

: 20 mm (0.79 in)

JPBIA0171ZZ

Compression pressure : Refer to