Nissan Juke F15. Manual - part 652

EM-162

< SYSTEM DESCRIPTION >

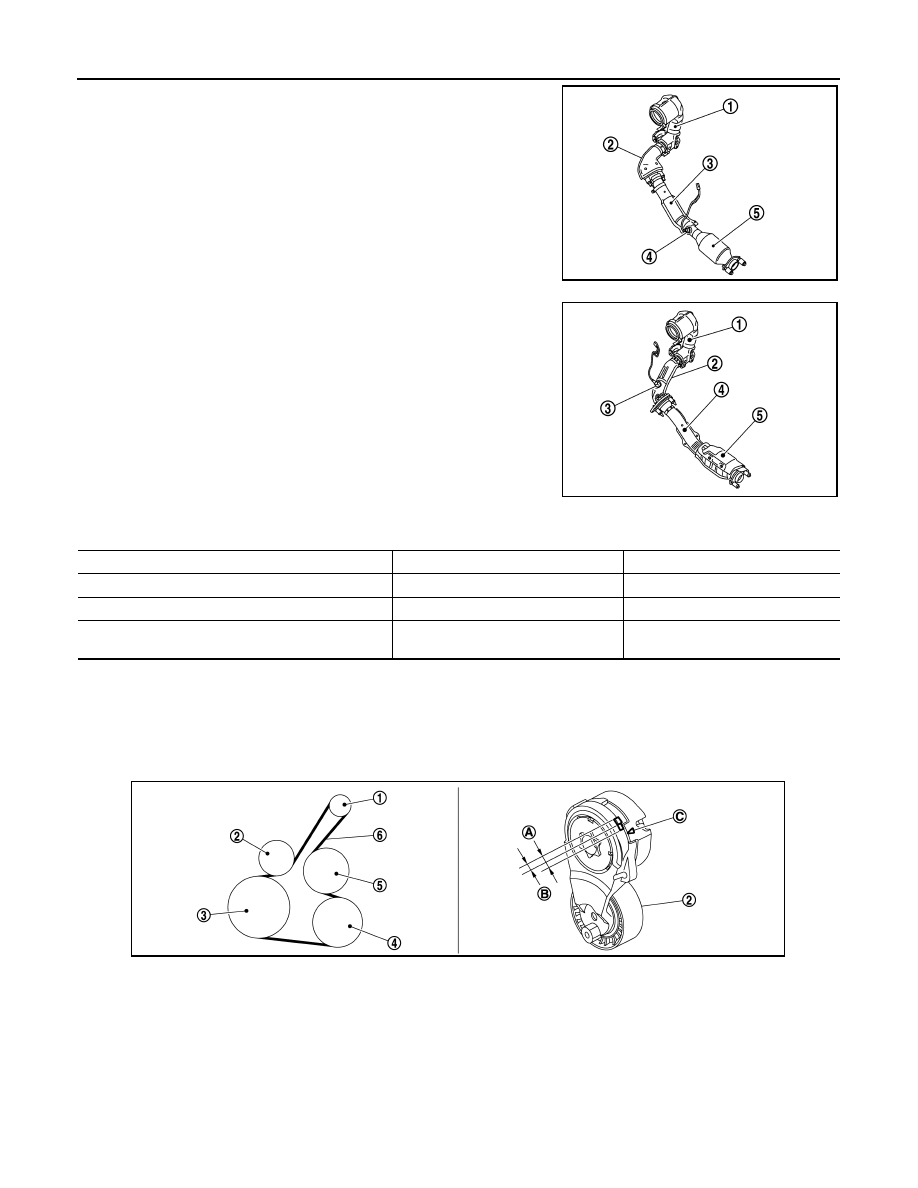

[MR EXCEPT FOR NISMO RS MODELS]

COMPONENT PARTS

- 2WD

- AWD

SPECIFICATION

Drive Belt

INFOID:0000000012197346

• A serpentine belt

*

that drives all auxiliary devices with a single belt is used.

*

Serpentine

• The drive belt auto tensioner is installed between the crank pulley and alternator.

SPECIFICATION

• The belt used is a V-ribbed 6PK belt.

• The drive belt auto tensioner mechanism contains a coil spring and uses the idler pulley to maintain appro-

priate belt tension at all times, making regular belt tension adjustment unnecessary.

1

: Catalyst converter (supercharger

exit)

2

: Catalyst converter adapter

3

: Front tube

4

: Heated oxygen sensor 2

5

: Three-way catalyst converter (un-

der floor)

JSBIA5738ZZ

1

: Catalyst converter (supercharger

exit)

2

: Catalyst converter adapter

3

: Heated oxygen sensor 2

4

: Front tube

5

: Three-way catalyst converter (un-

der floor)

JSBIA5739ZZ

Installation position

Supercharger exit

Underfloor

Structure

Monolithic (ceramic)

Monolithic (ceramic)

Capacity

liters (US qt, Imp qt)

0.92 (1, 6/8)

1.20 (1-2/8, 1)

Catalyst precious metal

types

Palladium, rhodium

Palladium, rhodium

1.

Alternator

2.

Drive belt auto tensioner

3.

Crankshaft pulley

4.

A/C compressor

5.

Water pump

6.

Drive belt

A. Usable range

B. Range for installation of new drive

belt

C. Indicator

JSBIA5907ZZ