Nissan Juke F15. Manual - part 640

EM-114

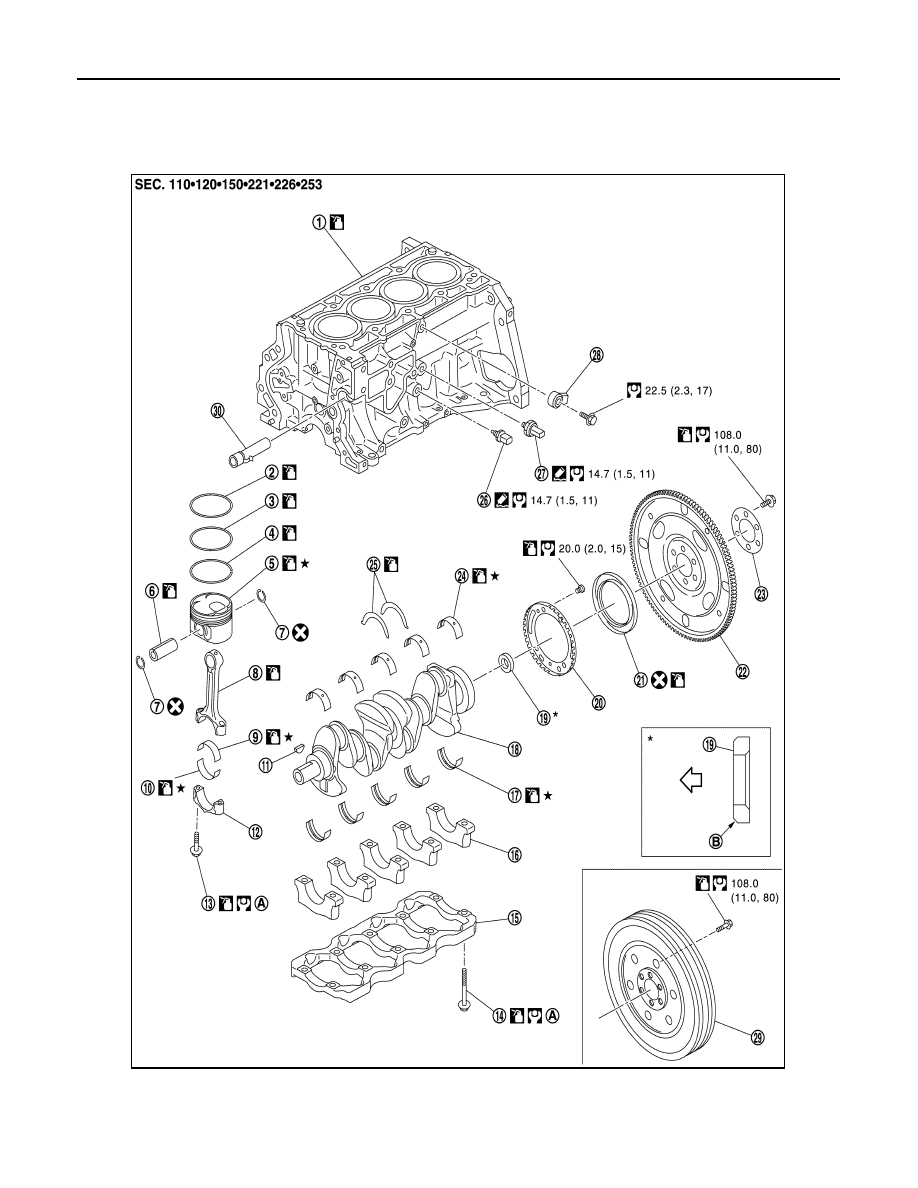

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR FOR NISMO RS MODELS]

CYLINDER BLOCK

CYLINDER BLOCK

Exploded View

INFOID:0000000012197309

1.

Cylinder block

2.

Top ring

3.

Second ring

4.

Oil ring

5.

Piston

6.

Piston pin

7.

Snap ring

8.

Connecting rod

9.

Connecting rod bearing (upper)

JPBIA5495GB