Nissan Juke F15. Manual - part 623

EM-46

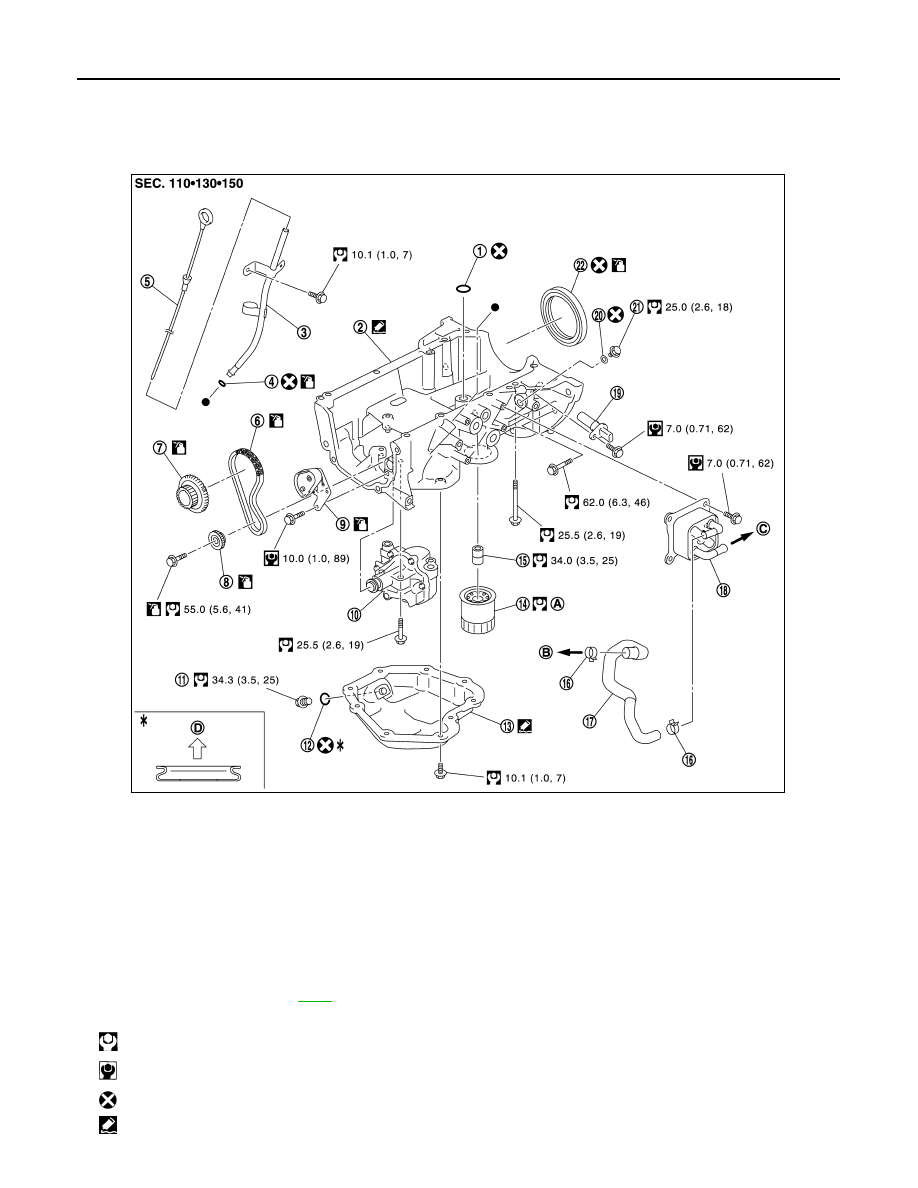

< REMOVAL AND INSTALLATION >

[MR FOR NISMO RS MODELS]

OIL PAN (LOWER)

OIL PAN (LOWER)

Exploded View

INFOID:0000000012197271

1.

O-ring

2.

Oil pan (upper)

3.

Oil level gauge guide

4.

O-ring

5.

Oil level gauge

6.

Oil pump drive chain

7.

Crankshaft sprocket

8.

Oil pump sprocket

9.

Oil pump chain tensioner

10. Oil pump

11. Drain plug

12. Drain plug washer

13. Oil pan (lower)

14. Oil filter

15. Connector bolt

16. Clamp 17. Water

hose

18. Oil

cooler

19. Crankshaft position sensor

20. Gasket

21. Oil pan bolt

22. Rear oil seal

A.

Comply with the assembly proce-

dure when tightening. Refer to

B.

To thermostat hosing

C.

To thermostat housing (M/T models)

To CVT oil warmer (CVT models)

D.

Oil pan side

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Always replace after every disassembly.

: Sealing point

JPBIA4875GB