Nissan Juke F15. Manual - part 562

P0643 SENSOR POWER SUPPLY

EC-1061

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is DTC detected?

YES

>> Proceed to

EC-1061, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000012198577

1.

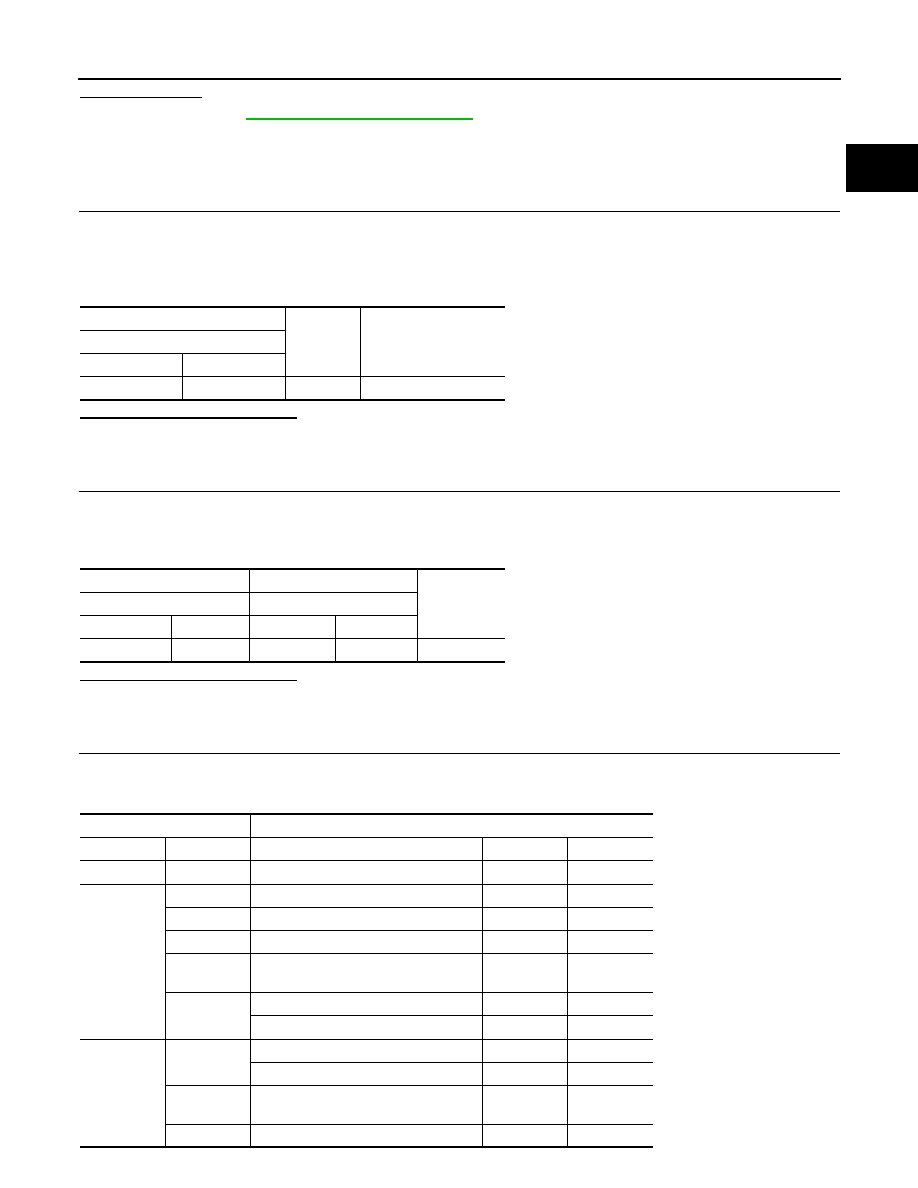

CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT-1

1. Turn ignition switch OFF.

2. Disconnect accelerator pedal position (APP) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between APP sensor harness connector and ground.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT-2

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between APP sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair open circuit.

3.

CHECK SENSOR POWER SUPPLY 1 CIRCUIT

1. Disconnect following sensors harness connector.

2. Check harness for short to power and short to ground, between the following terminals.

+

−

Voltage

(Approx.)

APP sensor

Connector

Terminal

E101

4

Ground

5 V

+

−

Continuity

APP sensor

ECM

Connector

Terminal

Connector

Terminal

E101

4

E19

146

Existed

ECM

Sensor

Connector

Terminal

Name

Connector

Terminal

E19

146

APP sensor 1

E101

4

F23

30

Battery current sensor

F52

1

27

Crankshaft position sensor

F107

3

30

EGR pressure sensor

F46

1

30

Intake manifold runner control valve po-

sition sensor

F73

1

30

Manifold absolute pressure sensor

F76

1

EGR volume control valve

F74

3

F24

61

Electric wastegate position sensor

F61

3

Multi-way control valve position sensor

F60

5

73

Exhaust valve timing control position

sensor

F111

1

83

Throttle position sensor

F29

5