Nissan Juke F15. Manual - part 530

P0234 TC SYSTEM

EC-933

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NO

>> Replace Turbocharger Assembly (do not replace electric wastegate control actuator only). Refer

to

EC-600, "ENGINE CONTROL SYSTEM : Component Parts Location"

Diagnosis Procedure

INFOID:0000000012198432

1.

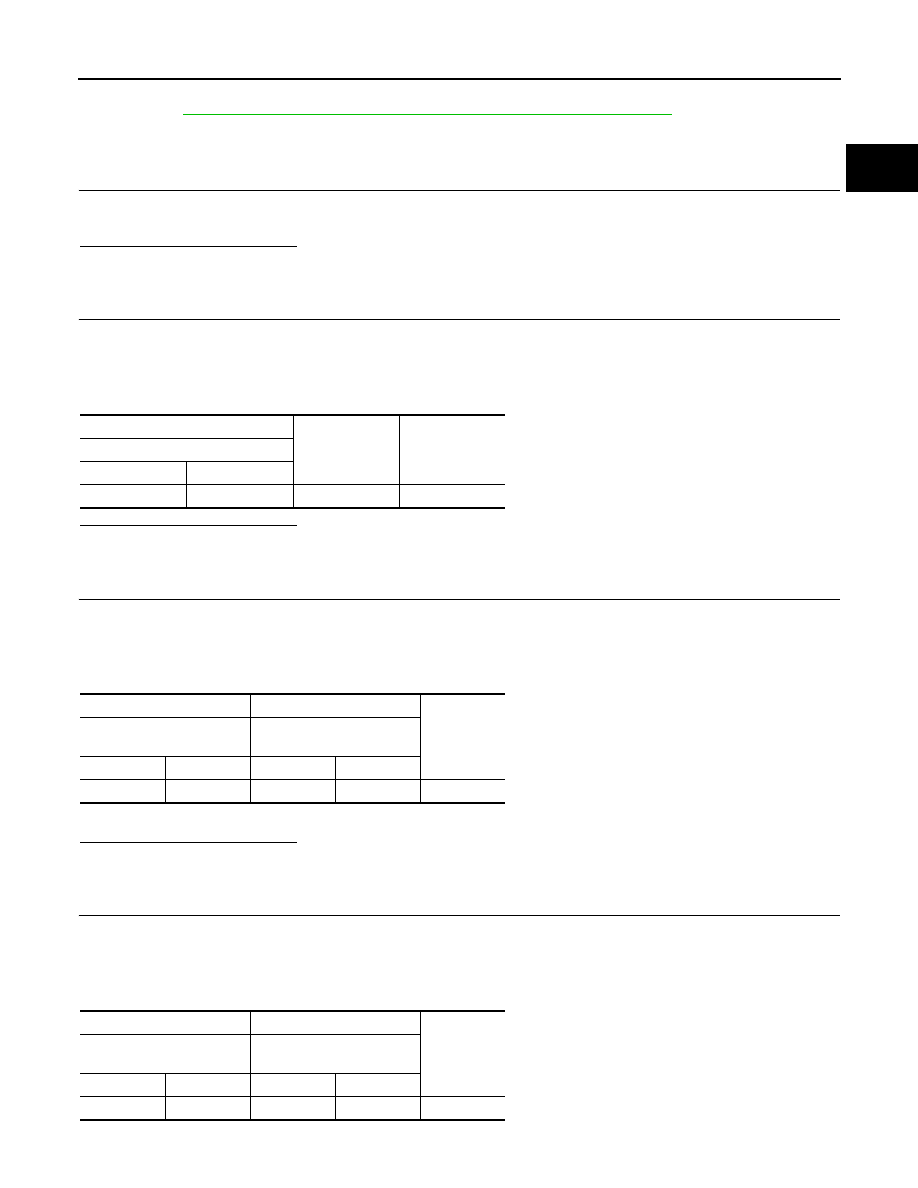

CHECK BOOST CONTROL ACTUATOR HOSE

Check disconnection, looseness or improper connection of hose between turbocharger bypass control valve

solenoid valve and boost control actuator.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace error-detected parts.

2.

CHECK TURBOCHARGER BYPASS CONTROL VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect turbocharger bypass control valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between turbocharger bypass control valve harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

CHECK TURBOCHARGER BYPASS CONTROL VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between turbocharger bypass control valve harness connector and IPDM E/R har-

ness connector.

4. Also check harness for short to ground and short.

Is the inspection result normal?

YES

>> Perform the trouble diagnosis for power supply circuit.

NO

>> Repair or replace error-detected parts.

4.

CHECK TURBOCHARGER BYPASS CONTROL VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between turbocharger bypass control valve harness connector and ECM harness

connector.

4. Also check harness for short to power.

+

−

Voltage

Turbocharger bypass control valve

Connector

Terminal

F64

1

Ground

Battery voltage

+

−

Continuity

Turbocharger bypass con-

trol valve

IPDM E/R

Connector

Terminal

Connector

Terminal

F64

1

E14

36

Existed

+

−

Continuity

Turbocharger bypass con-

trol valve

ECM

Connector

Terminal

Connector

Terminal

F64

2

F24

105

Existed