Nissan Juke F15. Manual - part 435

HIGH PRESSURE FUEL PUMP

EC-553

< DTC/CIRCUIT DIAGNOSIS >

[MR FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NO

>> Replace high pressure fuel pump. Refer to

.

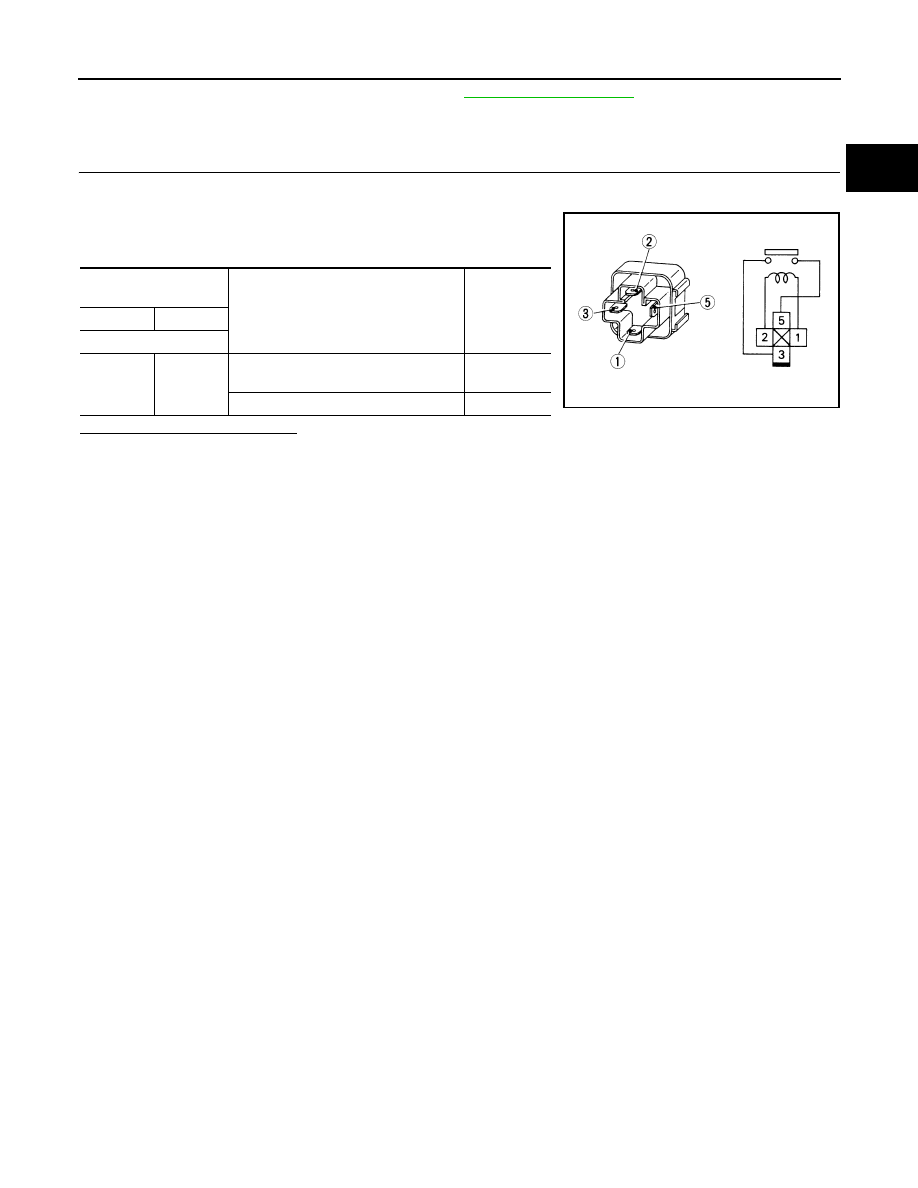

Component Inspection (High Pressure Fuel Pump Relay)

INFOID:0000000012198097

1.

CHECK HIGH PRESSURE FUEL PUMP RELAY

1. Turn ignition switch OFF.

2. Remove high pressure fuel pump relay.

3. Check the continuity between high pressure fuel pump relay ter-

minals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace high pressure fuel pump relay.

High pressure fuel

pump relay

Conditions

Continuity

+

−

Terminal

3

5

12 V direct current supply between ter-

minals 1 and 2

Existed

No current supply

Not existed

SEF090M