Nissan Juke F15. Manual - part 276

RING GEAR SHAFT

DLN-109

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21B]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

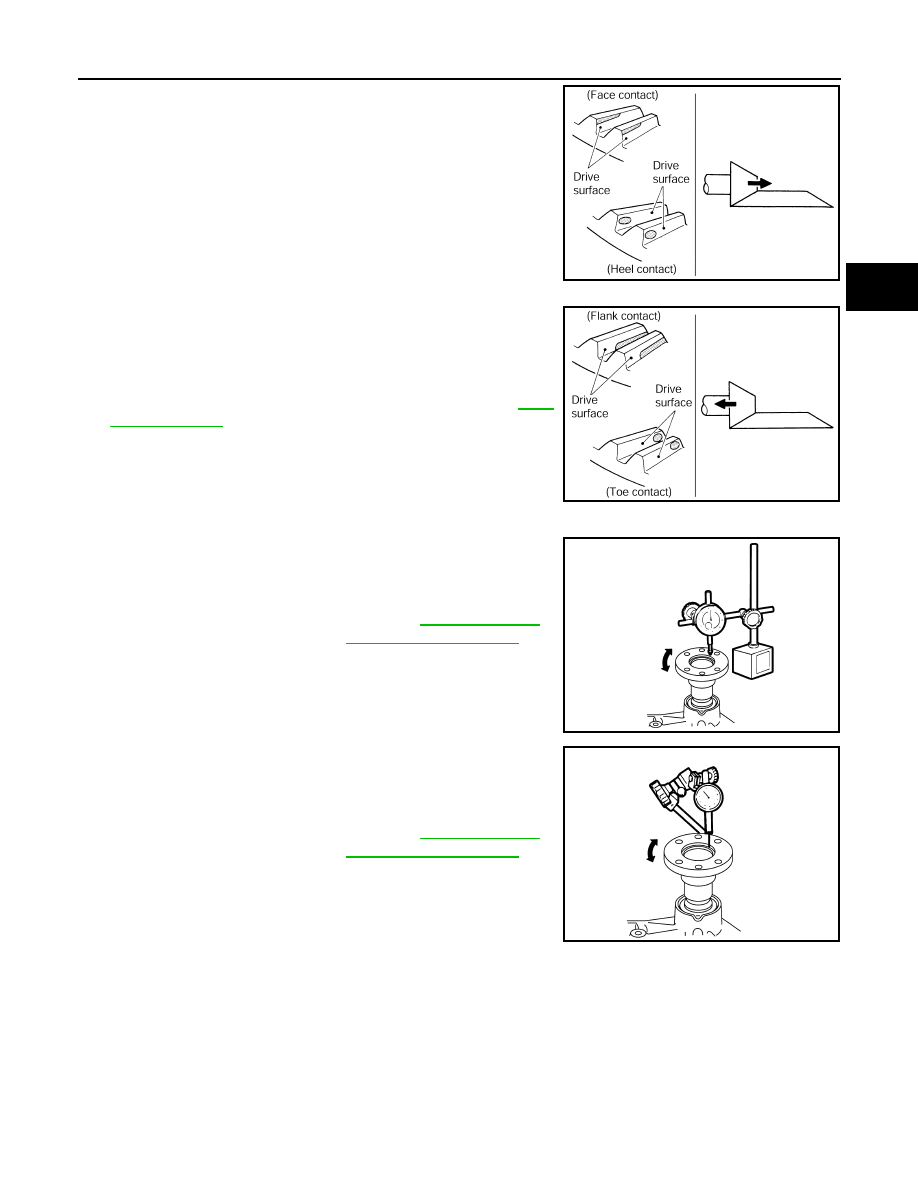

• Thicken the drive pinion adjusting shim to move the drive pin-

ion closer to the ring gear in case of face contact or heel con-

tact.

CAUTION:

Only one adjusting shim can be selected.

• Thin the drive pinion adjusting shim to move the drive pinion

farther from the ring gear in case of flank contact or toe con-

tact.

CAUTION:

Only one adjusting shim can be selected.

9. Reinstall transfer cover for applying liquid gasket. Refer to

COMPANION FLANGE RUNOUT

1. Fit a dial indicator onto the companion flange face (inner side of

the propeller shaft bolt holes).

2. Rotate the companion flange to check for runout.

3. Fit a test indicator to the inner side of the companion flange

(socket diameter).

4. Rotate the companion flange to check for runout.

5. Follow the procedure below to adjust if runout value is outside

the repair limit.

CAUTION:

Replace collapsible spacer to check and adjust each part

when companion flange is adjusted or replaced.

a. Check for runout while changing the phase between companion flange and drive pinion in 90

° steps. Then

search for the minimum point.

b. Replace companion flange if runout value is still outside the limit after the phase has been changed.

c. Adjust assembly status of the pinion bearings and drive pinion, or replace drive pinion bearings if runout is

outside the standard after the companion flange is replaced.

Inspection

INFOID:0000000012199469

INSPECTION AFTER DISASSEMBLY

Check items below. If necessary, replace them with new ones.

PDIA0440E

PDIA0441E

Companion flange runout

: Refer to

.

JSDIA2503ZZ

Companion flange runout

: Refer to

.

JSDIA2504ZZ