Content .. 1212 1213 1214 1215 ..

Nissan Juke F15. Manual - part 1214

TM-46

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

TRANSAXLE ASSEMBLY

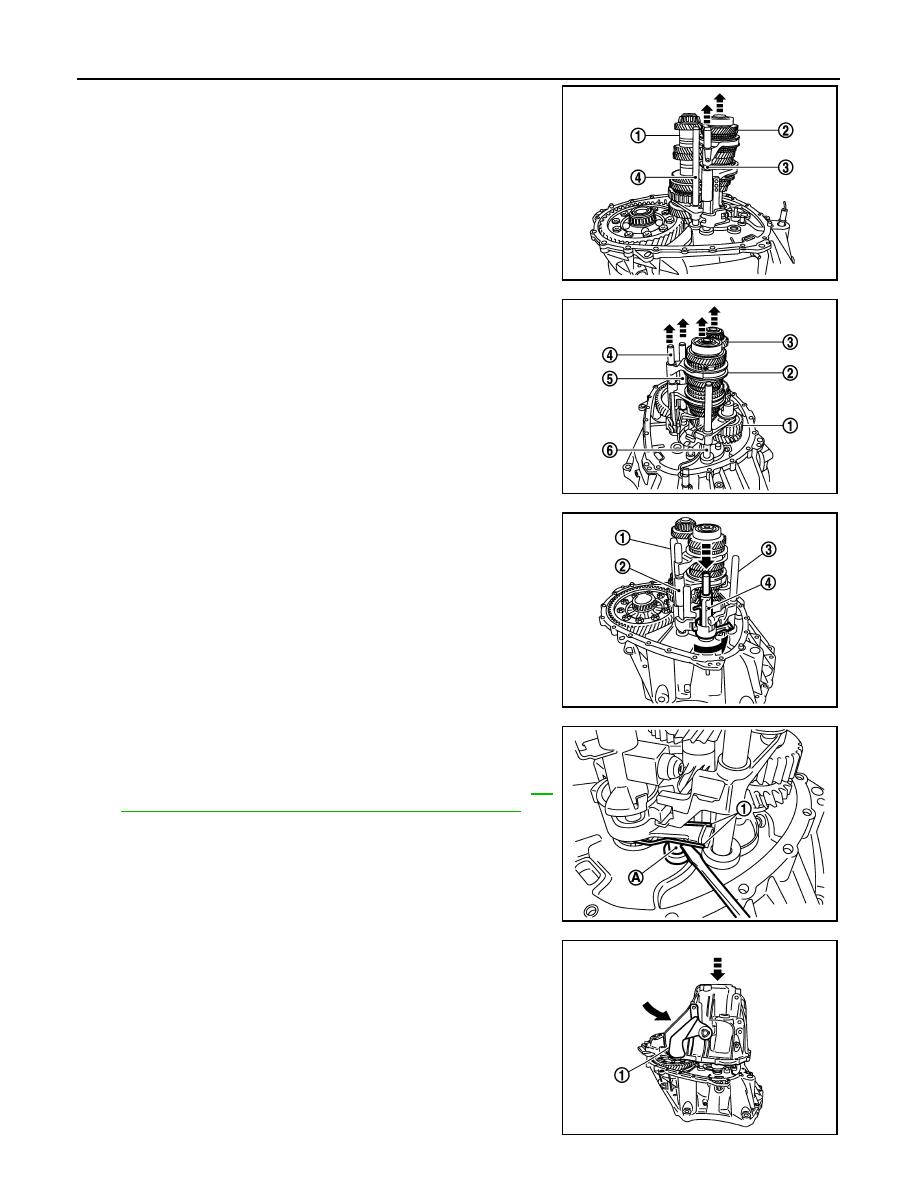

23. Install mainshaft assembly (1), as per the following procedure.

a. Pull up input shaft assembly (2) and fork rod (3).

b. Set 1st-2nd fork rod (4) to mainshaft assembly, and then install

them to clutch housing.

24. Install reverse idler shaft assembly (1), as per the following pro-

cedure.

a. Install spring washer to clutch housing.

b. Pull up input shaft assembly (2), mainshaft assembly (3), fork

rod (4), and 1st-2nd fork rod (5).

NOTE:

It is easier to pull up when shifting each fork rod to each shaft

side.

c.

Set reverse fork rod (6) to reverse idler shaft assembly, and then

install them to clutch housing.

25. Shift 1st-2nd fork rod (1), fork rod (2), and reverse fork rod (3) to

the neutral position.

26. Install selector (4) to clutch housing.

CAUTION:

Replace selector lever and selector as a set.

27. Install selector spring (1) to return bushing (A).

28. Apply recommended sealant to mounting surface of transaxle

case.

• Use Genuine Silicone RTV or an equivalent. Refer to

22, "Recommended Chemical Products and Sealants"

.

CAUTION:

• Never allow old liquid gasket, moisture, oil, or foreign

matter to remain on mounting surface.

• Check that mounting surface is not damaged.

• Apply sealant bead continuously.

29. Install transaxle case to clutch housing while rotating shifter

lever A (1) in the direction as shown in the figure.

JPDIC0609ZZ

JPDIC0606ZZ

SCIA7782E

JPDIC0445ZZ

JPDIC0110ZZ