Content .. 1077 1078 1079 1080 ..

Nissan Juke F15. Manual - part 1079

RAX-8

< REMOVAL AND INSTALLATION >

[2WD]

REAR WHEEL HUB

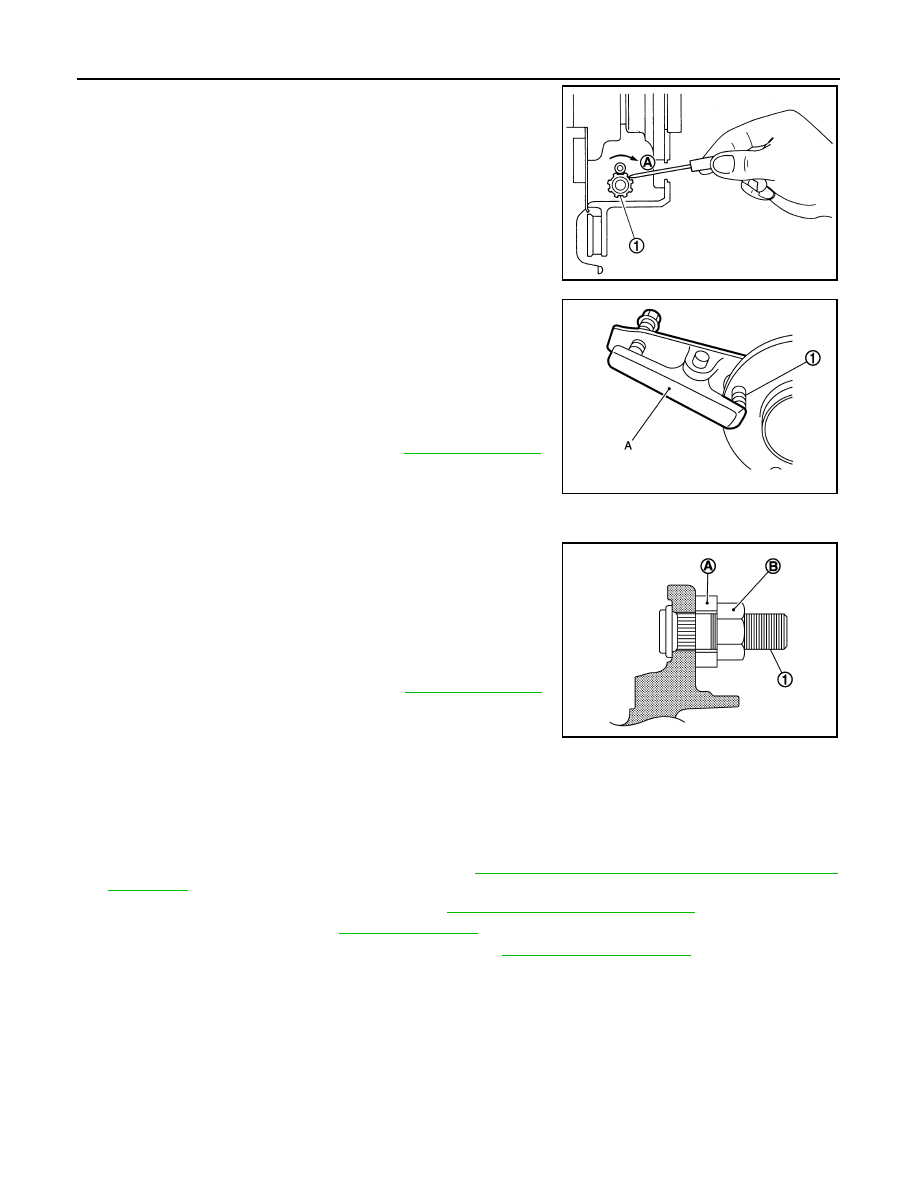

b. Using suitable tool, rotate adjuster (1) in the direction (A) to

retract and loosen brake shoe.

c.

Remove disc rotor.

5. Remove wheel hub assembly.

CAUTION:

Never remove parking brake assembly. Protect it from fall-

ing.

6. Remove hub bolts (1) from wheel hub assembly, using the ball

joint remover (A) (commercial service tool).

CAUTION:

• Remove hub bolt only when necessary.

• Never hammer the hub bolt to avoid impact to the wheel

hub assembly.

• Pull out the hub bolt in a direction perpendicular to the

wheel hub assembly.

7. Perform inspection after removal. Refer to

.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Place a washer (A) as shown in the figure to install the hub bolts

(1) by using the tightening force of the nut (B).

CAUTION:

• Check that there is no clearance between wheel hub assem-

bly and hub bolt.

• Never reuse hub bolt.

• Align the matching marks that have been made during removal

when reusing the disc rotor.

• Perform inspection after installation. Refer to

.

Inspection

INFOID:0000000012196552

INSPECTION AFTER REMOVAL

Check the wheel hub assembly for wear, cracks, and damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection.

BRC-150, "REAR WHEEL SENSOR : Removal and

.

2. Adjust parking brake operation (stroke). Refer to

PB-11, "Inspection and Adjustment"

3. Check wheel alignment. Refer to

4. Adjust neutral position of steering angle sensor. Refer to

.

JPDIG0204ZZ

JPDIF0299ZZ

JPDIF0300ZZ