содержание .. 746 747 748 749 ..

Nissan Tiida C11. Manual - part 748

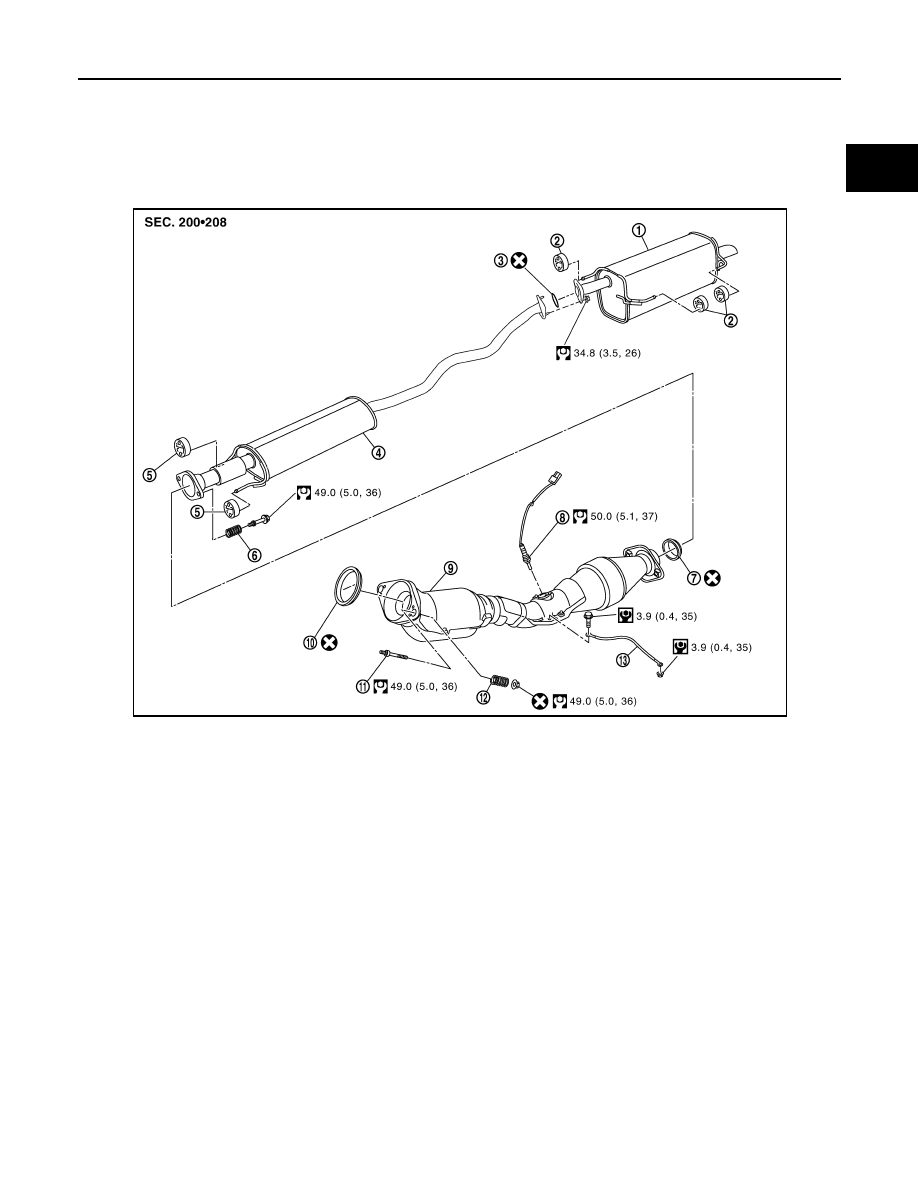

EXHAUST SYSTEM

EX-5

< ON-VEHICLE REPAIR >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EX

N

P

O

ON-VEHICLE REPAIR

EXHAUST SYSTEM

Component

INFOID:0000000001337859

Removal and Installation

INFOID:0000000001337860

REMOVAL

CAUTION:

• Be sure to use genuine NISSAN exhaust system parts or equivalents which are specially designed

for heat resistance, corrosion resistance and shape.

• Perform the operation with the exhaust system fully cooled down because the system will be hot

just after the engine stops.

• Be careful not to cut your hand on heat insulator edge.

1.

Disconnect harness connector of heated oxygen sensor 2.

• Using Tool, remove heated oxygen sensor 2.

CAUTION:

Be careful not to damage heated oxygen sensor 2.

a.

1.

Main muffler

2.

Mounting rubber

3.

Ring gasket

4.

Center muffler

5.

Mounting rubber

6.

Spring

7.

Seal bearing

8.

Heated oxygen sensor 2

9.

Exhaust front tube

10. Seal bearing

11. Stud bolt

12. Spring

13. Ground cable

WBIA0844E

Tool number

: KV10114400 (J-38365)