содержание .. 598 599 600 601 ..

Nissan Tiida C11. Manual - part 600

EC-1050

< BASIC INSPECTION >

[K9K]

INSPECTION AND ADJUSTMENT

3.

Check the continuity between high pressure supply pump (volumetric control valve) harness connector

and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

11.

CHECK HIGH PRESSURE SUPPLY PUMP (VOLUMETRIC CONTROL VALVE)-II

EC-1110, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Replace high pressure supply pump.

12.

CHECK HIGH PRESSURE SUPPLY PUMP (PRESSURE CONTROL VALVE) POWER SUPPLY

1.

Turn ignition switch OFF.

2.

Disconnect high pressure supply pump (pressure control valve) harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between high pressure supply pump (pressure control valve) harness connector and

ground.

Is the inspection result normal?

YES

>> GO TO 14.

NO

>> GO TO 13.

13.

DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R

• Harness for open or short between IPDM E/R and high pressure supply pump (pressure control valve)

• Harness for open or short between ECM and high pressure supply pump (pressure control valve)

>> Repair open circuit or short to ground or short to power in harness or connectors.

14.

CHECK HIGH PRESSURE SUPPLY PUMP (PRESSURE CONTROL VALVE) OUTPUT SIGNAL CIR-

CUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between high pressure supply pump (pressure control valve) harness connector and

ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

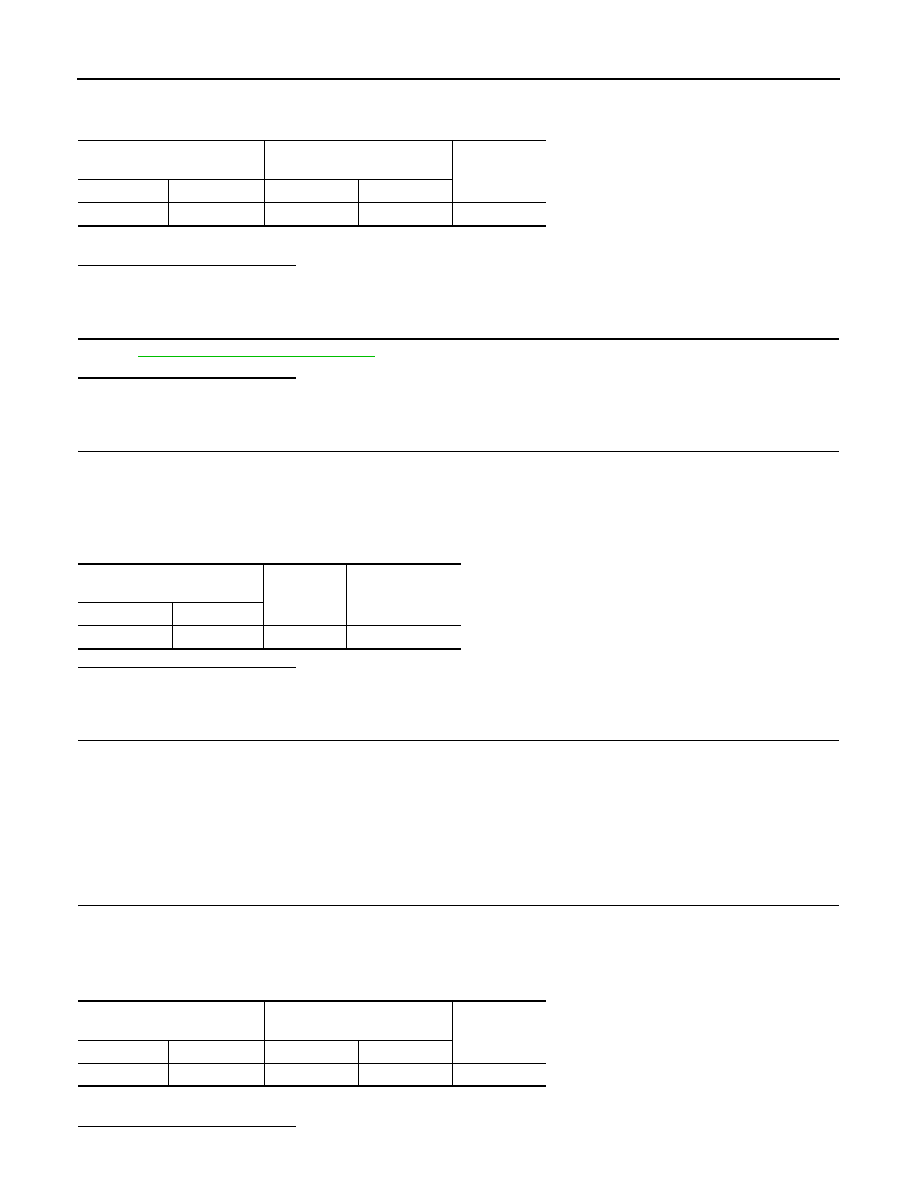

High pressure supply pump

(volumetric control valve)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F54

2

F11

50

Existed

High pressure supply pump

(Pressure control valve)

Ground

Voltage

Connector

Terminal

F53

3

Ground

Battery voltage

High pressure supply pump

(Pressure control valve)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F53

4

F11

49

Existed