содержание .. 490 491 492 493 ..

Nissan Tiida C11. Manual - part 492

EC-618

< COMPONENT DIAGNOSIS >

[HR16DE (WITHOUT EURO-OBD)]

HO2S2

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 7.

7.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool and approved anti-seize lubricant.

>> INSPECTION END

8.

CHECK INTERMITTENT INCIDENT

GI-55, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000001697502

1.

INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK HEATED OXYGEN SENSOR 2

With CONSULT-III

1.

Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2.

Start engine and warm it up to the normal operating temperature.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5.

Let engine idle for 1 minute.

6.

Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select “HO2S2 (B1)” as the monitor item with

CONSULT-III.

7.

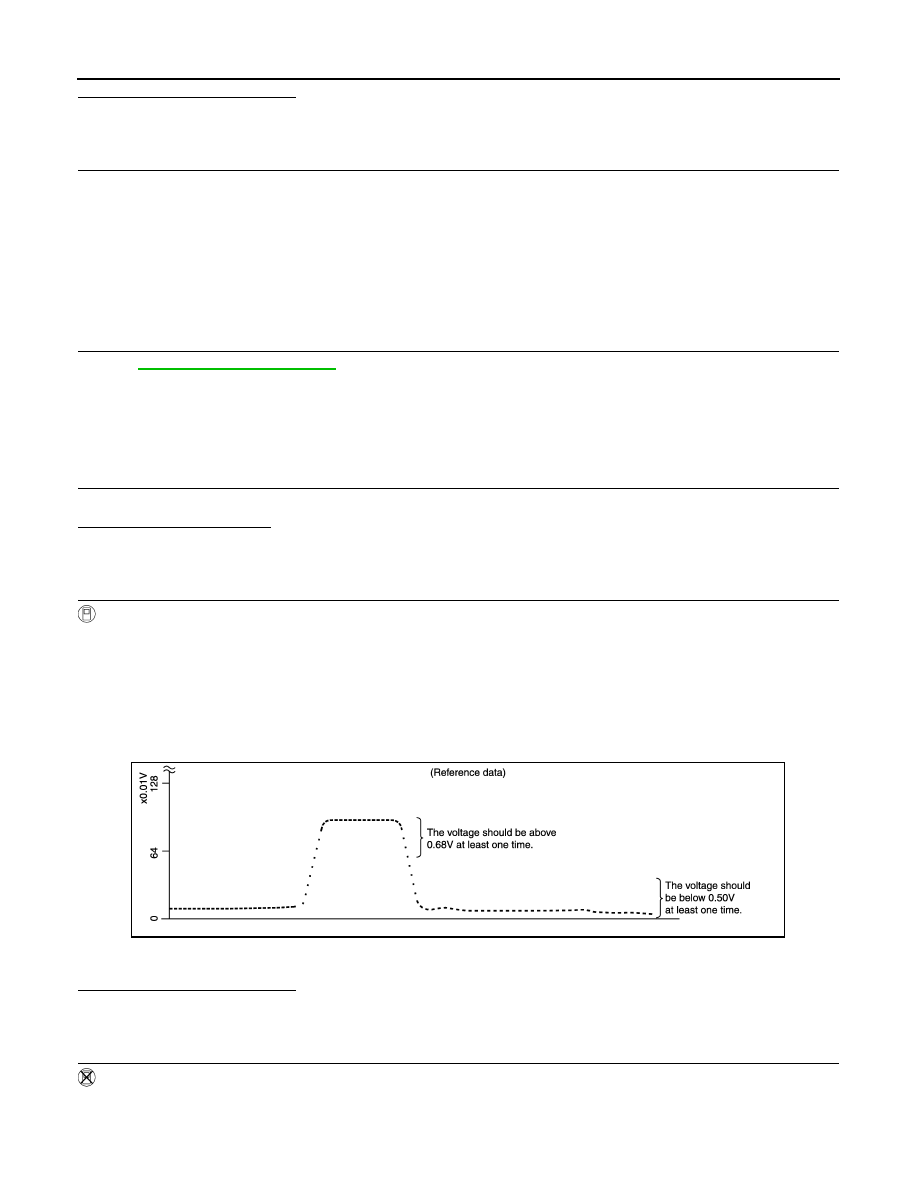

Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to

±

25%.

“HO2S2 (B1)” should be above 0.68V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)” should be below 0.50V at least once when the “FUEL INJECTION” is

−

25%.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 6.

3.

CHECK HEATED OXYGEN SENSOR 2-I

Without CONSULT-III

1.

Start engine and warm it up to the normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

PBIB0551E