содержание .. 380 381 382 383 ..

Nissan Tiida C11. Manual - part 382

EC-178

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0141 HO2S2 HEATER

Component Inspection

INFOID:0000000001670944

1.

CHECK HEATED OXYGEN SENSOR 2 HEATER

1.

Turn ignition switch OFF.

2.

Disconnect heated oxygen sensor 2 harness connector.

3.

Check resistance between HO2S2 terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool and approved anti-seize lubricant.

>> INSPECTION END

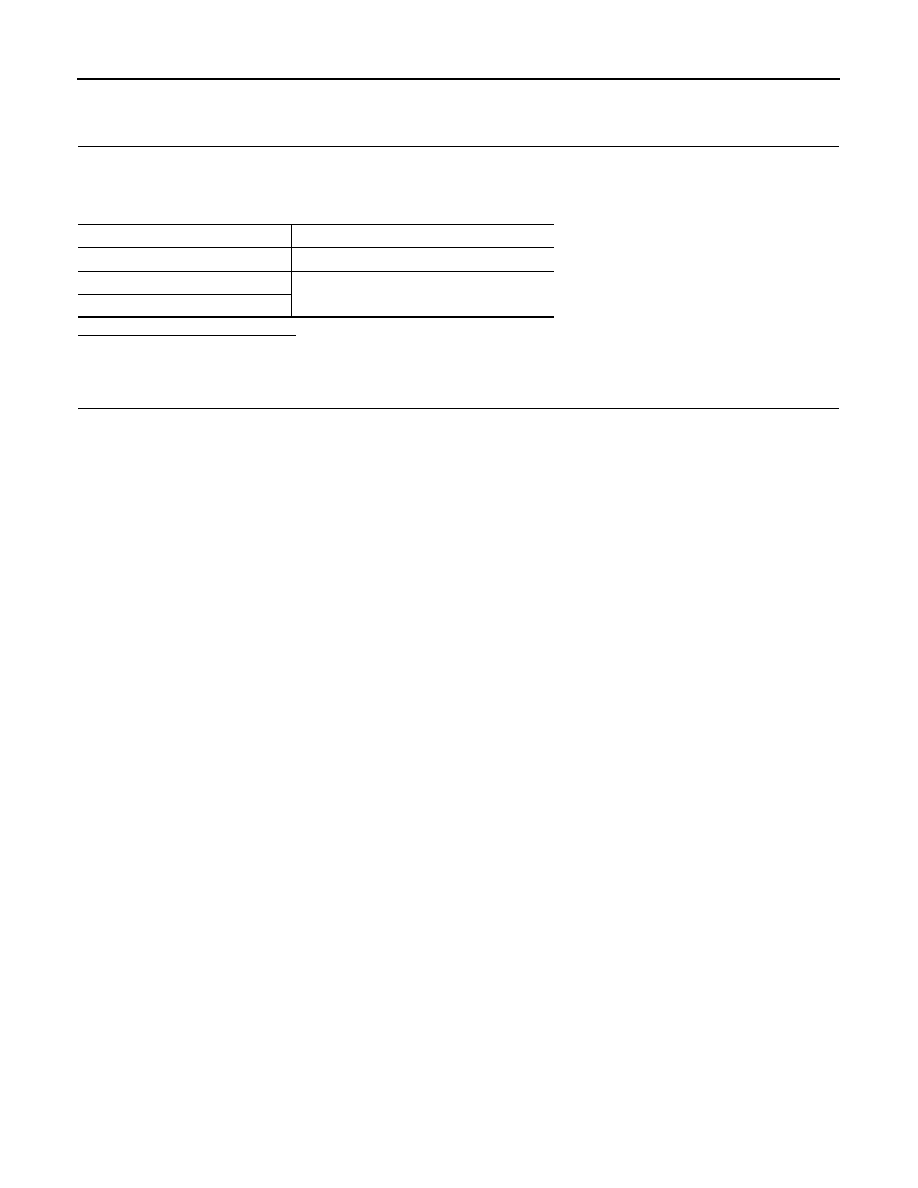

Terminals

Resistance [at 25

°

C (77

°

F)

2 and 3

3.3 - 4.4

Ω

1 and 2, 3, 4

∞

Ω

(Continuity should not exist)

4 and 1, 2, 3