содержание .. 378 379 380 381 ..

Nissan Tiida C11. Manual - part 380

EC-170

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0139 HO2S2

P0139 HO2S2

Description

INFOID:0000000001670936

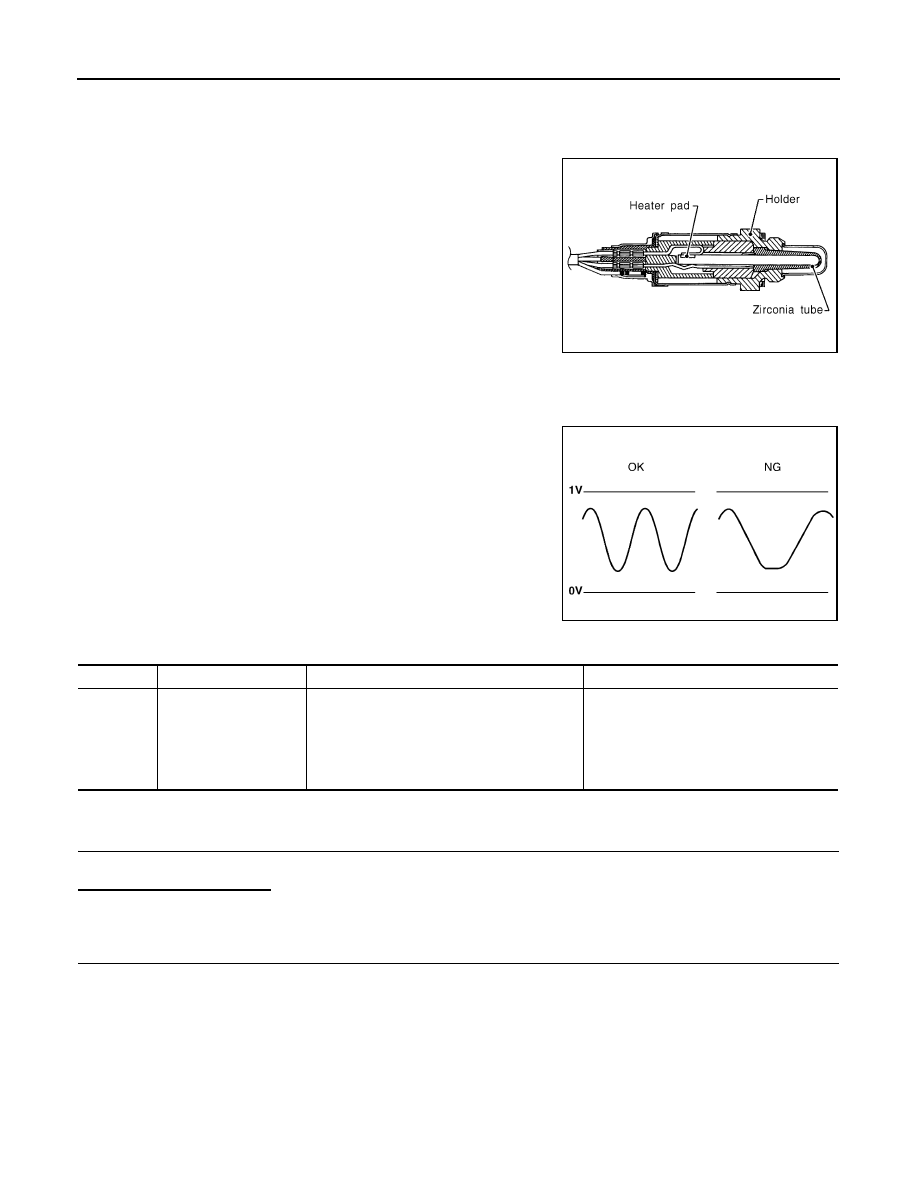

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the heated oxygen sensor 1 are

shifted, the air-fuel ratio is controlled to stoichiometric, by the signal

from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

DTC Logic

INFOID:0000000001670937

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

DTC CONFIRMATION PROCEDURE

1.

INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III?

YES

>> GO TO 2.

NO

>> GO TO 11.

2.

PRECONDITIONING

“COMPLETED” will appear on CONSULT-III screen when all tests “COND1”, “COND2” and “COND3” are

completed.

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION

For the best results, perform DTC WORK SUPPORT at a temperature of 0 to 30

°

C (32 to 86

°

F).

Never stop engine during this procedure. If the engine is stopped, retry this procedure from PERFORM PRO-

CEDURE FOR COND1 - II.

SEF327R

SEF302U

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0139

Heated oxygen sensor 2

circuit slow response

It takes more time for the sensor to respond be-

tween rich and lean than the specified time.

• Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks