содержание .. 1381 1382 1383 1384 ..

Nissan Tiida C11. Manual - part 1383

REPAIR FOR COMPONENT PARTS

TM-583

< DISASSEMBLY AND ASSEMBLY >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

INSPECTION

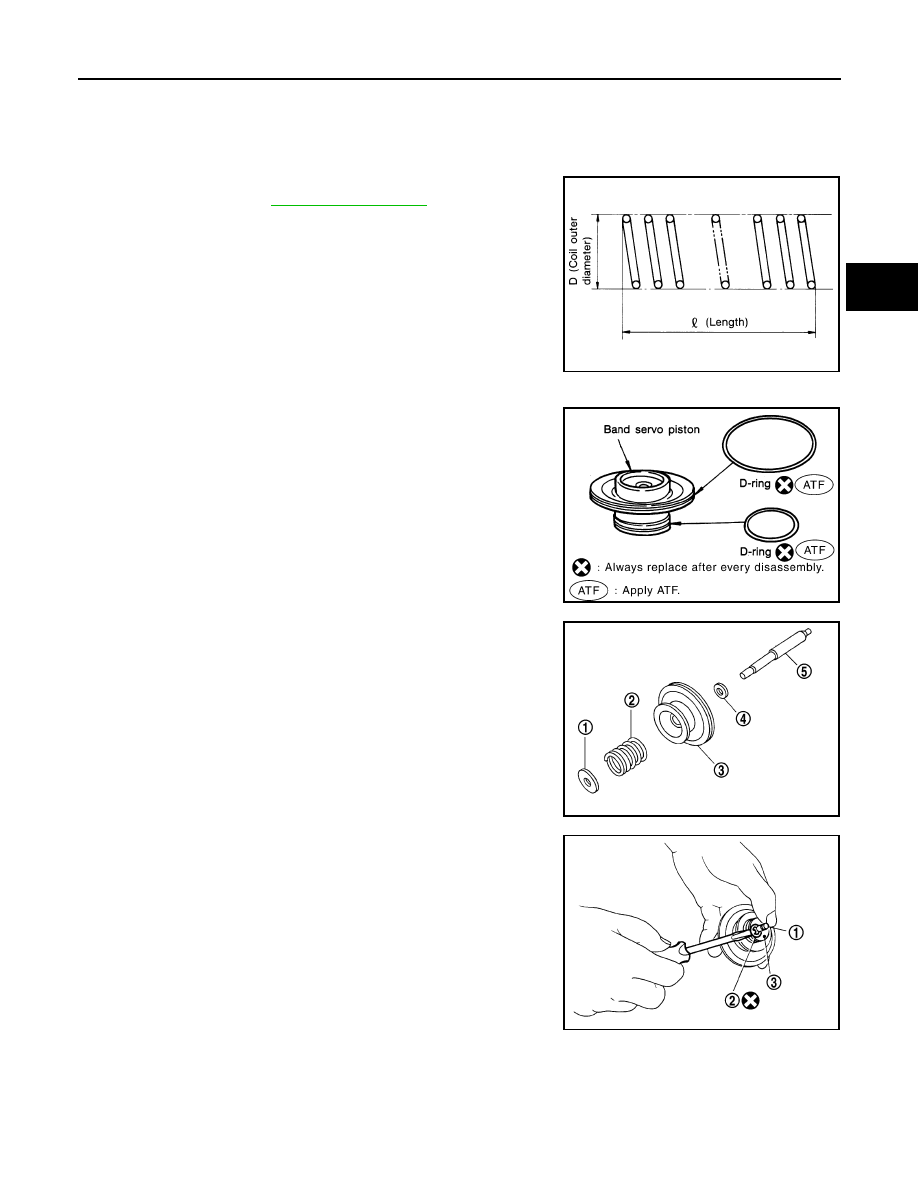

Pistons, Retainers and Piston Stem

Check the sliding surfaces for damage or excessive wear. Replace if necessary.

Return Springs

• Check each return spring for damage or deformation. Also mea-

sure free length. Refer to

• Replace springs if deformed or fatigued.

ASSEMBLY

1.

Install D-rings to band servo piston.

2.

Install band servo thrust washer (4), band servo piston (3), OD

servo return spring (2) and spring retainer (1) to band servo pis-

ton stem (5).

3.

Place band servo piston stem (1) on a wooden block, and install

E-ring (2) to band servo piston stem (1) while pressing spring

retainer (3) downward.

SAT138D

SCIA3688E

SCIA7054E

SCIA7056E