содержание .. 133 134 135 136 ..

Nissan Tiida C11. Manual - part 135

CO-58

< ON-VEHICLE MAINTENANCE >

[K9K]

ENGINE COOLANT

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

Inspection

INFOID:0000000001381585

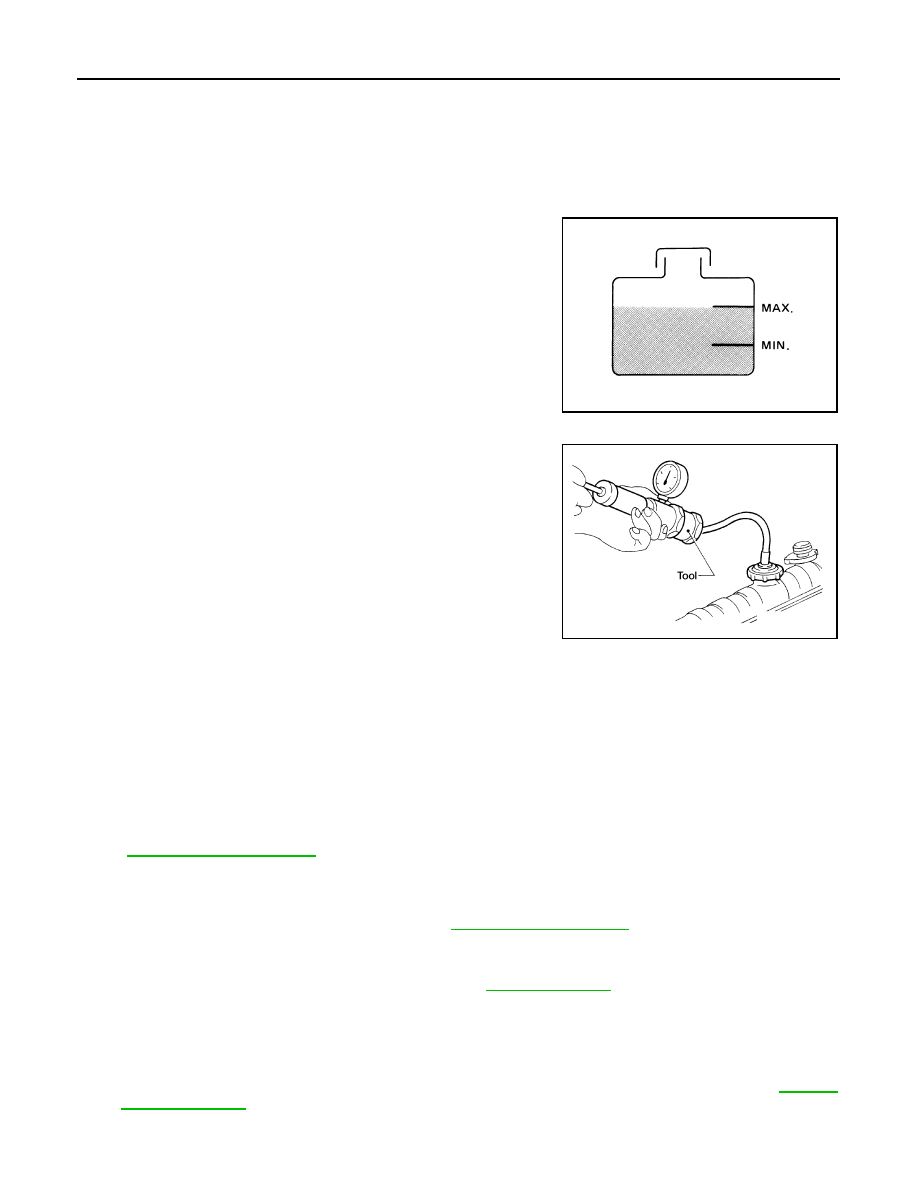

LEVEL CHECK

• Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

• Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Draining

INFOID:0000000001381586

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

• Be careful not to allow engine coolant to contact drive belt.

1.

Remove engine undercover using power tool.

2.

Disconnect radiator hose (lower) from radiator and remove reservoir tank cap.

When draining all of engine coolant in the system, open water drain plug on cylinder block. Refer

to

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

3.

Remove air relief plug from water outlet. Refer to

.

4.

Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

5.

Check drained coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to

.

Refilling

INFOID:0000000001381587

• Before starting work, turn off the automatic air conditioner and the blower motor.

1.

Install reservoir tank if removed, lower radiator hose and air relief plug.

• If water drain plug on cylinder block is removed, install and tighten it. Refer to

.

2.

Fill reservoir tank slowly with coolant until coolant spills from the air relief hole.

SMA412B

Testing pressure

: 157 kPa (1.6 kg/cm

2

, 23 psi)

WBIA0568E