содержание .. 1338 1339 1340 1341 ..

Nissan Tiida C11. Manual - part 1340

A/T TCC S/V FUNCTION (LOCK-UP)

TM-411

< COMPONENT DIAGNOSIS >

[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

10.

CHECK DTC

Perform

TM-408, "DTC Confirmation Procedure"

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 11.

11.

CHECK LOCK-UP

During

XX-XX, "*****"

.

A/T perform lock-up at the specified speed?

YES

>> Perform

XX-XX, "*****"

again and return to the start

point of this test group.

NO

>> GO TO 12.

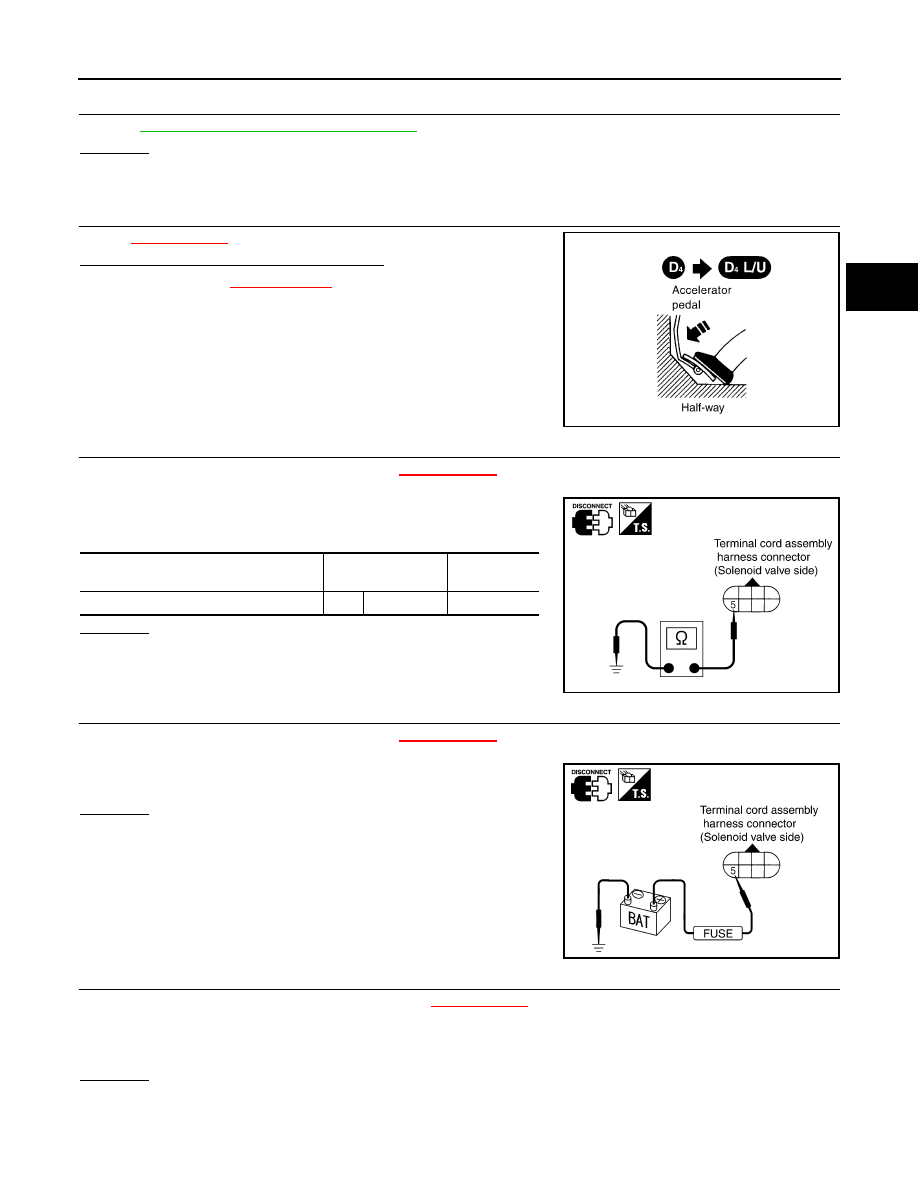

12.

CHECK VALVE RESISTANCE

1.

Remove control valve assembly. Refer to

XX-XX, "*****"

.

-

Torque converter clutch solenoid valve

2.

Check resistance between terminal cord assembly harness con-

nector terminal and ground.

OK or NG

OK

>> GO TO 13.

NG

>> Replace solenoid valve assembly.

13.

CHECK VALVE OPERATION

1.

Remove control valve assembly. Refer to

XX-XX, "*****"

.

-

Torque converter clutch solenoid valve

2.

Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

OK or NG

OK

>> GO TO 14.

NG

>> Replace solenoid valve assembly.

14.

CHECK CONTROL VALVE

1.

Disassemble control valve assembly. Refer to

XX-XX, "*****"

.

2.

Check control valves for sticking.

-

Torque converter clutch control valve

-

Torque converter clutch relief valve

OK or NG

OK

>> GO TO 15.

NG

>> Repair or replace control valve.

SCIA7191E

Solenoid valve

Terminal

Resistance

(Approx.)

Torque converter clutch solenoid valve

5

Ground

5 - 20

Ω

SCIA2063E

SCIA2066E