содержание .. 1316 1317 1318 1319 ..

Nissan Tiida C11. Manual - part 1318

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-323

< SERVICE DATA AND SPECIFICATIONS (SDS)

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

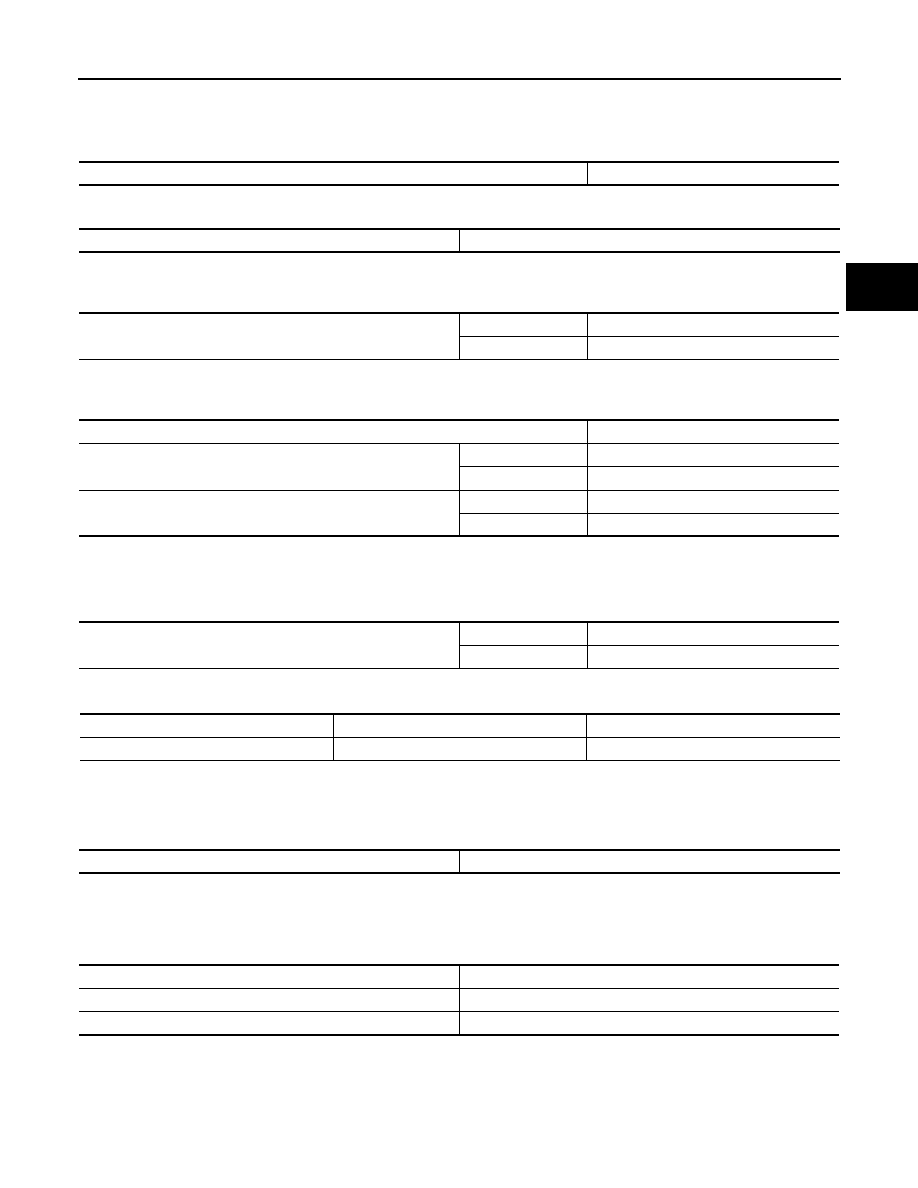

Final Drive

INFOID:0000000001731396

DIFFERENTIAL SIDE GEAR CLEARANCE

DIFFERENTIAL SIDE BEARING END PLAY

Planetary Carrier

INFOID:0000000001731397

Oil Pump

INFOID:0000000001731398

Input Shaft

INFOID:0000000001731399

SEAL RING CLEARANCE

SEAL RING

Unit: mm (in)

Reduction Pinion Gear

INFOID:0000000001731400

TURNING TORQUE

Band Servo

INFOID:0000000001731401

RETURN SPRINGS

Unit: mm (in)

Output Shaft

INFOID:0000000001731402

SEAL RING CLEARANCE

Clearance between side gear and differential case with washer [mm (in)]

0.1 - 0.2 (0.004 - 0.008)

Differential side bearing end play [mm (in)]

0 - 0.15 (0 - 0.0059)

Clearance between planetary carrier and pinion washer [mm (in)]

Standard

0.15 - 0.70 (0.0059 - 0.0276)

Allowable limit

0.80 (0.0315)

Oil pump side clearance

0.02 - 0.04 (0.0008 - 0.0016)

Clearance between oil pump housing and outer gear [mm (in]

Standard

0.08 - 0.15 (0.0031 - 0.0059)

Allowable limit

0.15 (0.0059)

Oil pump cover seal ring clearance [mm (in)]

Standard

0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit

0.25 (0.0098)

Input shaft seal ring clearance [mm (in)]

Standard

0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit

0.25 (0.098)

Outer diameter

Inner diameter

Width

24 (0.94)

20.4 (0.803)

1.97 (0.0776)

Turning torque of reduction pinion gear [N·m (kg-m, in-lb)]

0.11 - 0.69 (0.02 - 0.07, 1 - 6)

Return spring

Free length

2nd servo return spring

32.5 (1.280)

OD servo return spring

38.52 (1.5165)