содержание .. 1313 1314 1315 1316 ..

Nissan Tiida C11. Manual - part 1315

ASSEMBLY

TM-311

< DISASSEMBLY AND ASSEMBLY >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

3.

Adjust reverse clutch end play “T

2

”.

• Select proper thickness of thrust washer so that reverse clutch end play is within specifications.

Assembly (3)

INFOID:0000000001731000

1.

Remove reverse clutch assembly.

2.

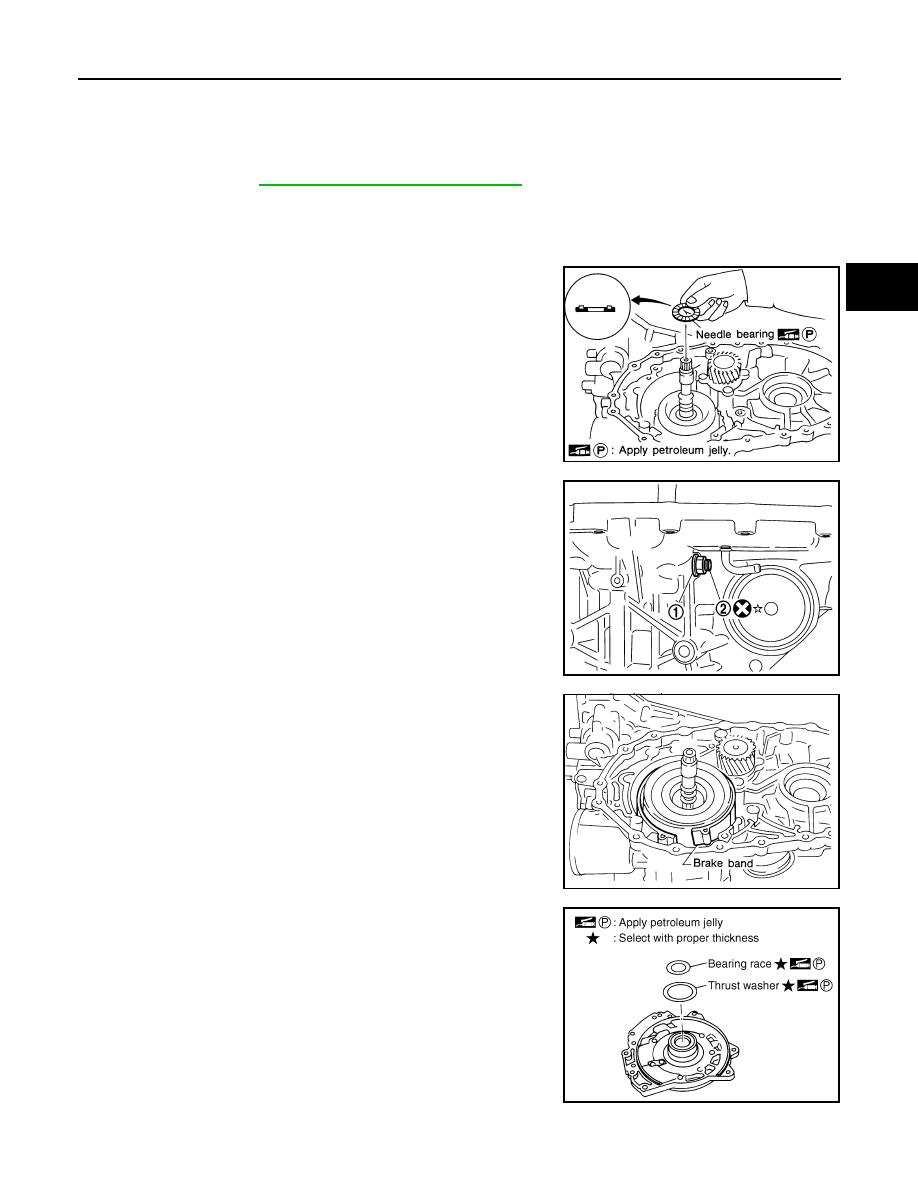

Install needle bearing on input shaft assembly (high clutch

drum).

CAUTION:

Be careful with the direction of needle bearing.

3.

Install reverse clutch assembly.

CAUTION:

Align teeth of reverse clutch drive plates before installing.

4.

Install anchor end pin (2) and lock nut (1) on transaxle case.

5.

Place brake band on outside of reverse clutch drum.

6.

Tighten anchor end pin just enough so that brake band is evenly

fitted on reverse clutch drum.

7.

Install bearing race selected in total end play adjustment step on

oil pump cover.

8.

Install thrust washer selected in reverse clutch end play adjust-

ment step on oil pump cover.

9.

Install O-ring to oil pump assembly.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

T

2

= N – Q

Reverse clutch end play:

TM-324, "Reverse Clutch End Play"

SAT387D

SCIA6037J

SAT038D

SCIA3629E