содержание .. 126 127 128 129 ..

Nissan Tiida C11. Manual - part 128

CO-30

< SYMPTOM DIAGNOSIS >

[MR18DE]

OVERHEATING CAUSE ANALYSIS

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

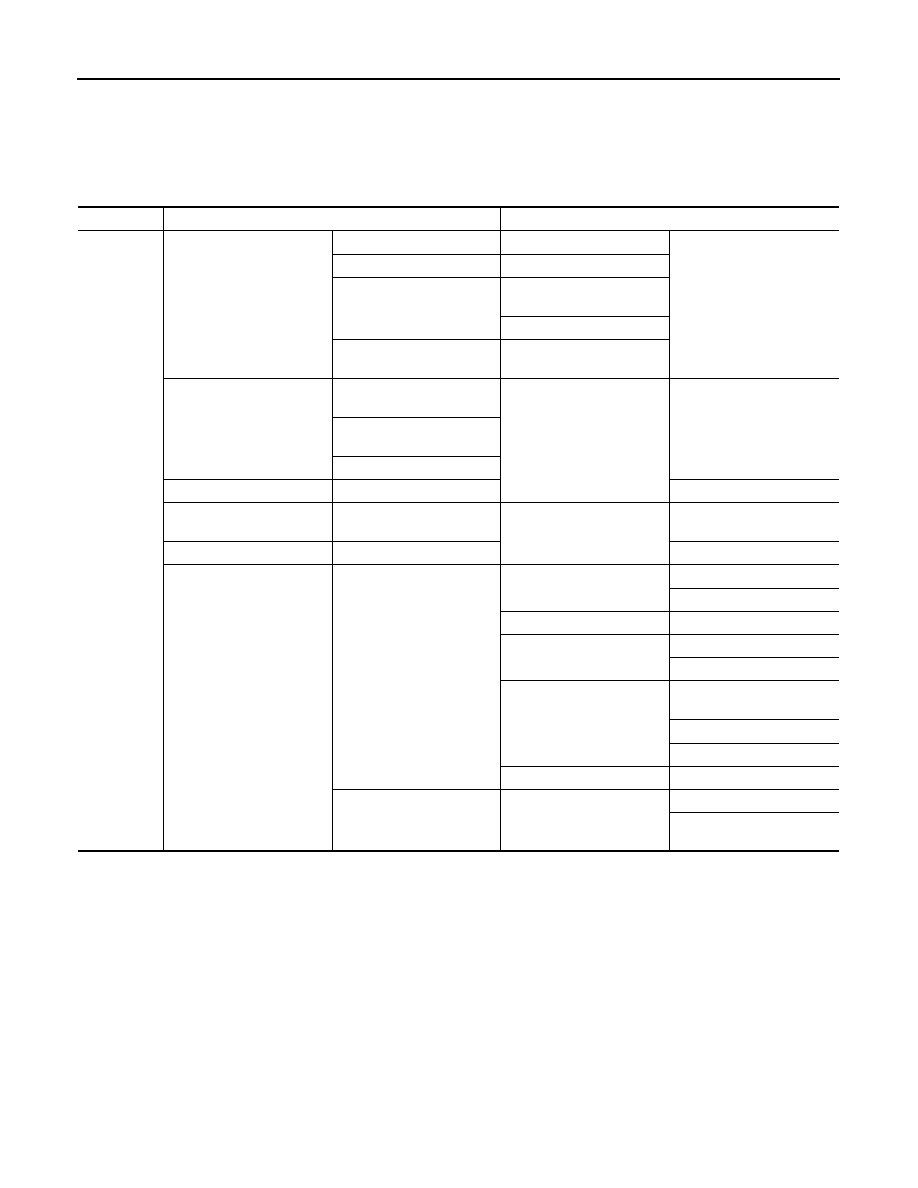

Troubleshooting Chart

INFOID:0000000001337836

Symptom

Check items

Cooling sys-

tem parts

malfunction

Poor heat transfer

Water pump malfunction

Worn or loose drive belt

—

Thermostat stuck closed

Thermostat

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube

Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow

Cooling fan does not oper-

ate

Fan assembly

—

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud

—

—

Improper engine coolant

mixture ratio

—

—

Engine coolant viscosity

—

Poor engine coolant quality

—

—

Insufficient engine coolant

Engine coolant leaks

Cooling hose

Loose clamp

Cracked hose

Water pump

Poor sealing

Radiator cap

Loose

Poor sealing

Radiator

O-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank

Cracked reservoir tank

Overflowing reservoir tank

Exhaust gas leaks into cool-

ing system

Cylinder head deterioration

Cylinder head gasket deteri-

oration