содержание .. 1119 1120 1121 1122 ..

Nissan Tiida C11. Manual - part 1121

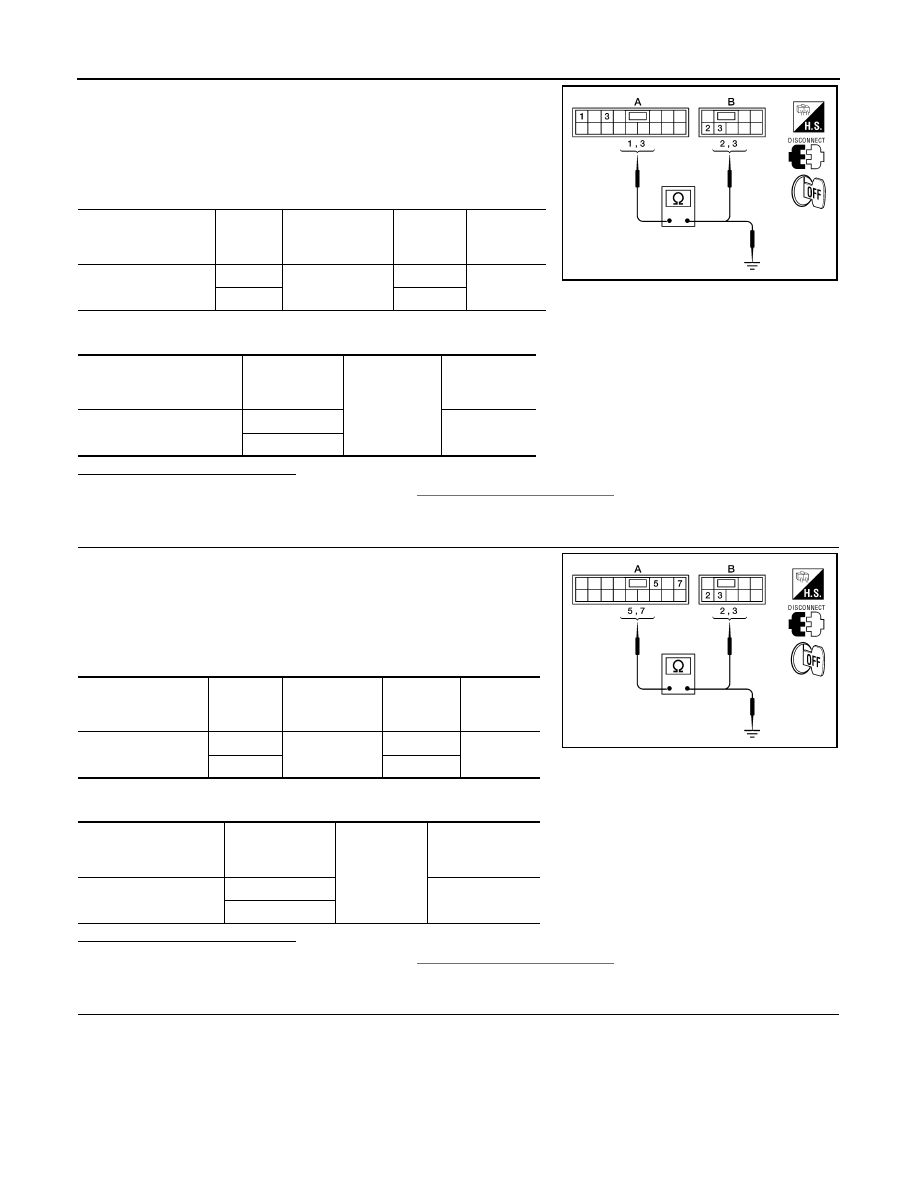

PWC-20

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect main power window and door lock/unlock switch and

rear power window switch LH.

3.

Check continuity between main power window and door lock/

unlock switch connector (A) and rear power window switch LH

connector (B).

4.

Check continuity between main power window and door lock/unlock switchh connector (A) and ground.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-55, "Intermittent Incident"

.

NO

>> Repair or replace harness.

3.

CHECK HARNESS CONTINUITY (REAR POWER WINDOW SWITCH RH)

1.

Turn ignition switch OFF.

2.

Disconnect main power window and door lock/unlock switch and

rear power window switch RH.

3.

Check continuity between main power window and door lock/

unlock switch connector (A) and rear power window switch RH

connector (B).

4.

Check continuity between main power window and door lock/unlock switch connector (A) and ground.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-55, "Intermittent Incident"

.

NO

>> Repair or replace harness.

4.

CHECK HARNESS CONTINUITY

Main power window

and door lock/unlock

switch connector

Terminal

Rear power win-

dow switch LH

connector

Terminal

Continuity

D7 (A)

1

D203 (B)

2

Yes

3

3

Main power window and

door lock/unlock switch

connector

Terminal

Ground

Continuity

D7 (A)

1

No

3

ALKIA0278ZZ

Main power window

and door lock/unlock

switch connector

Terminal

Rear power

window switch

RH connector

Terminal

Continuity

D7 (A)

5

D303 (B)

3

Yes

7

2

Main power window

and door lock/unlock

switch connector

Terminal

Ground

Continuity

D7 (A)

5

No

7

ALKIA0279ZZ