содержание .. 1052 1053 1054 1055 ..

Nissan Tiida C11. Manual - part 1054

LU-6

< ON-VEHICLE MAINTENANCE >

[HR16DE]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

Inspection

INFOID:0000000001381527

ENGINE OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1.

Pull out oil level gauge and wipe it clean.

2.

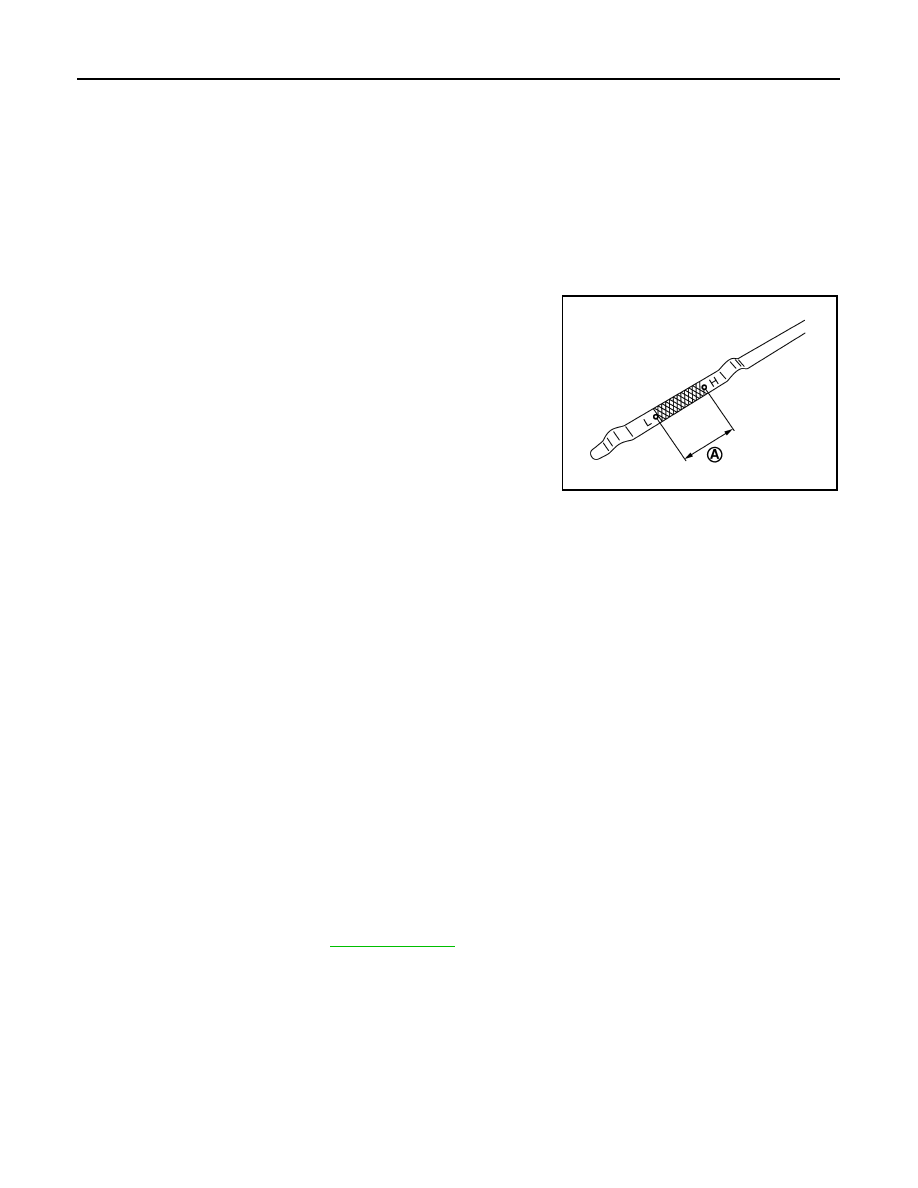

Insert oil level gauge and make sure the engine oil level is within

the range (A) shown in the figure.

3.

If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white turbidity or heavy contamination.

• If engine oil becomes turbid and white, it is highly probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKAGE

Check for engine oil leakage around the following area.

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil level sensor

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder head and camshaft bracket

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• When checking engine oil pressure, shift position should be “Neutral”, and apply parking brake

securely.

1.

Check engine oil level. Refer to

.

JPBIA0554ZZ