содержание .. 67 68 69 70 ..

Nissan Tiida C11. Manual - part 69

BRC-42

< COMPONENT DIAGNOSIS >

[ABS]

C1115 WHEEL SENSOR

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

YES

>> GO TO 4

NO

>> Adjust tire pressure or replace tire(s).

4.

CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to

FAX-6, "On-Vehicle Inspection and Service"

"On-Vehicle Inspection and Service"

(rear).

Is the inspection result normal?

YES

>> GO TO 5

NO

>> Repair or replace as necessary. Refer to

FAX-7, "Removal and Installation"

(front) or

(rear).

5.

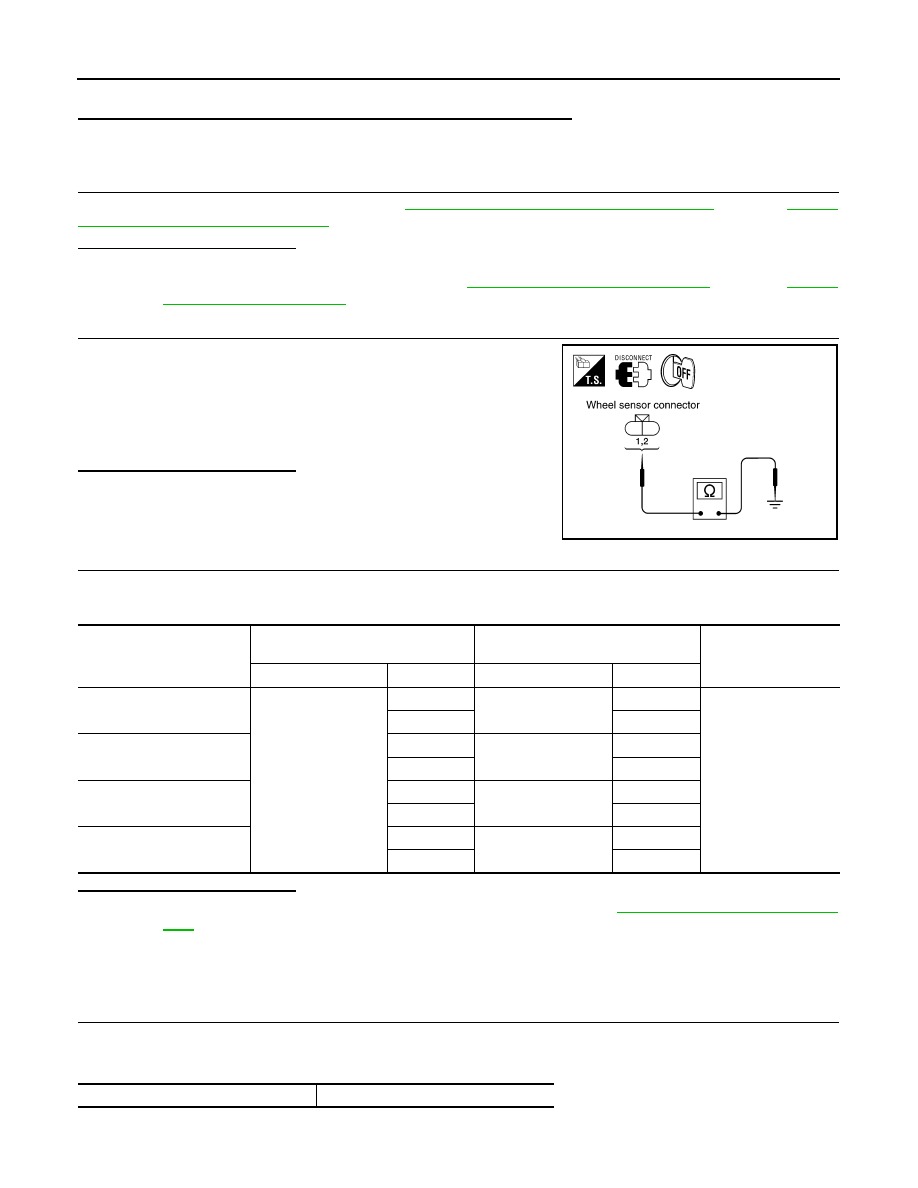

CHECK WIRING HARNESS FOR SHORT CIRCUIT

1.

Disconnect ABS actuator and electric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

2.

Check continuity between wheel sensor harness connector ter-

minals and ground.

Is the inspection result normal?

YES

>> GO TO 6

NO

>> Repair the circuit.

6.

CHECK WIRING HARNESS FOR OPEN CIRCUIT

1.

Check continuity between ABS actuator and electric unit (control unit) harness connector E125 and the

malfunctioning wheel sensor harness connector E18, E117, C10, or C11.

Is the inspection result normal?

YES

>> Replace the ABS actuator and electric unit (control unit). Refer to

BRC-85, "Removal and Installa-

.

NO

>> Repair the circuit.

Component Inspection

INFOID:0000000001731255

1.

CHECK DATA MONITOR

On “DATA MONITOR”, select “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR”, and “RR RH SEN-

SOR”, and check the vehicle speed.

Continuity should not exist.

WFIA0343E

Wheel sensor

ABS actuator and

electric unit (control unit)

Wheel sensor

Continuity

Connector

Terminal

Connector

Terminal

Front LH

E125

45

E18

1

Yes

46

2

Front RH

34

E117

1

33

2

Rear LH

37

C11

2

36

1

Rear RH

42

C10

2

43

1

Wheel sensor

Vehicle speed (DATA MONITOR)