содержание .. 66 67 68 69 ..

Nissan Tiida C11. Manual - part 68

BRC-38

< COMPONENT DIAGNOSIS >

[ABS]

C1110, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

C1110, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

DTC Logic

INFOID:0000000001731239

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001731240

INSPECTION PROCEDURE

1.

REPLACE ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

>> Replace ABS actuator and electric unit (control unit). Refer to

BRC-85, "Removal and Installa-

.

Special Repair Requirement

INFOID:0000000001731241

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform neutral position adjustment for the steering angle sensor when replacing the ABS actuator

and electric unit (control unit). Refer to

BRC-90, "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

.

>> GO TO 2

2.

CALIBRATION OF DECEL G SENSOR

Always perform calibration of decel G sensor when replacing the ABS actuator and electric unit (control unit).

Refer to

BRC-91, "CALIBRATION OF DECEL G SENSOR : Description"

.

>> END

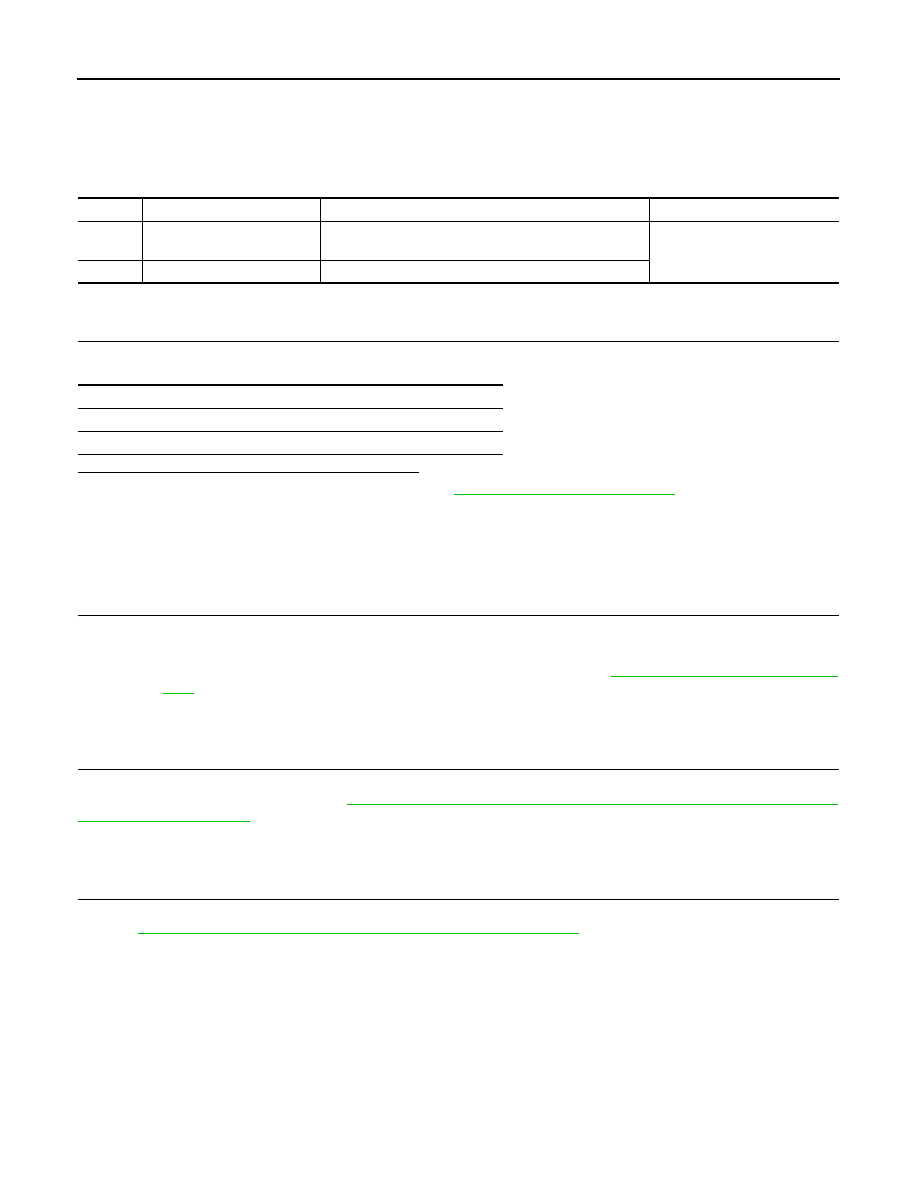

DTC

Display item

Malfunction detected condition

Possible cause

C1110

CONTROLLER FAILURE

When there is an internal malfunction in the ABS actuator

and electric unit (control unit).

• ABS actuator and electric unit

(control unit)

C1170

VARIANT CODING

In a case where VARIANT CODING is different.

Self-diagnosis results

CONTROLLER FAILURE

VARIANT CODING