содержание .. 56 57 58 59 ..

Nissan Tiida C11. Manual - part 58

REAR DISC BRAKE

BR-39

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

5.

Attach the sliding pin bolt and sliding pin boot to the torque member.

6.

Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the rear of the pad and to both sides

of the shim, and attach the inner shim and shim cover to the inner pad, and the outer shim and outer shim

cover to the outer pad.

7.

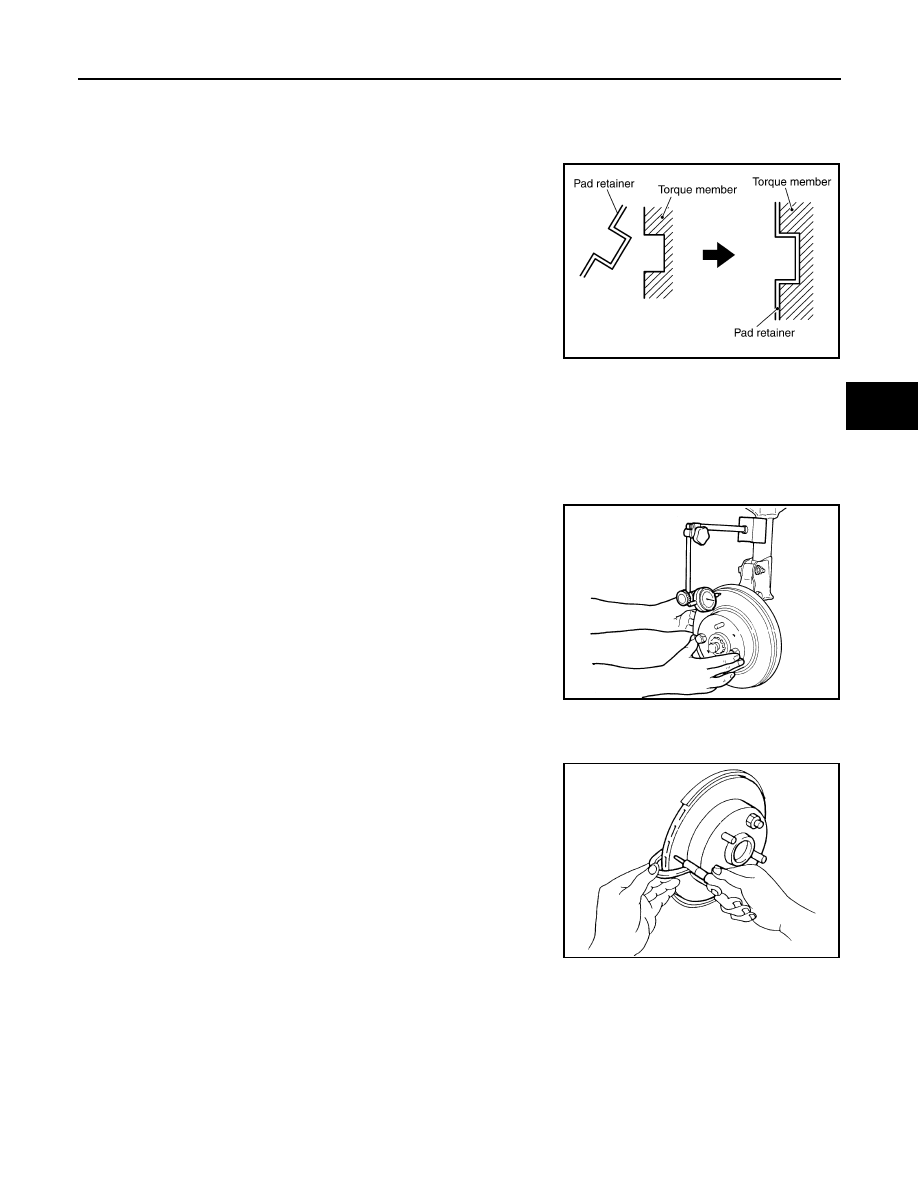

Attach the pad retainer and pad to the torque member.

CAUTION:

When attaching the pad retainer, attach it firmly so that it

does not float up higher than the torque member, as shown

in the figure.

8.

After assembling shims and shim covers to pad, install it to the

torque member.

9.

Install cylinder body. Tighten sliding pin bolts to the specified

torque.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks, and serious damage. If any non-standard condition is

detected, replace applicable part.

Runout Inspection

1.

Using wheel nuts, fix disc rotor to the wheel hub in two or more positions.

2.

Inspect runout using a dial gauge.

CAUTION:

Before measuring, make sure the axle endplay is 0 mm (0

in).

3.

If runout is outside the limit, find the minimum runout point by

shifting mounting positions of the disc rotor and wheel hub by

one hole.

Thickness Inspection

Using a micrometer, check thickness of the disc rotor. If thickness is

not within specification, replace disc rotor.

PFIA0273E

Measurement position

: At a point 10 mm (0.39 in)

from outer edge of the disc.

Runout limit (with it at-

tached to the vehicle)

: 0.07 mm (0.0028 in) or less

BRA0013D

Standard thickness

: 9.0 mm (0.350 in)

Minimum thickness

: 8.0 mm (0.310 in)

Maximum uneven wear

(measured at 8 positions)

: 0.015 mm (0.0006 in) or

less

SBR020B