содержание .. 53 54 55 56 ..

Nissan Tiida C11. Manual - part 55

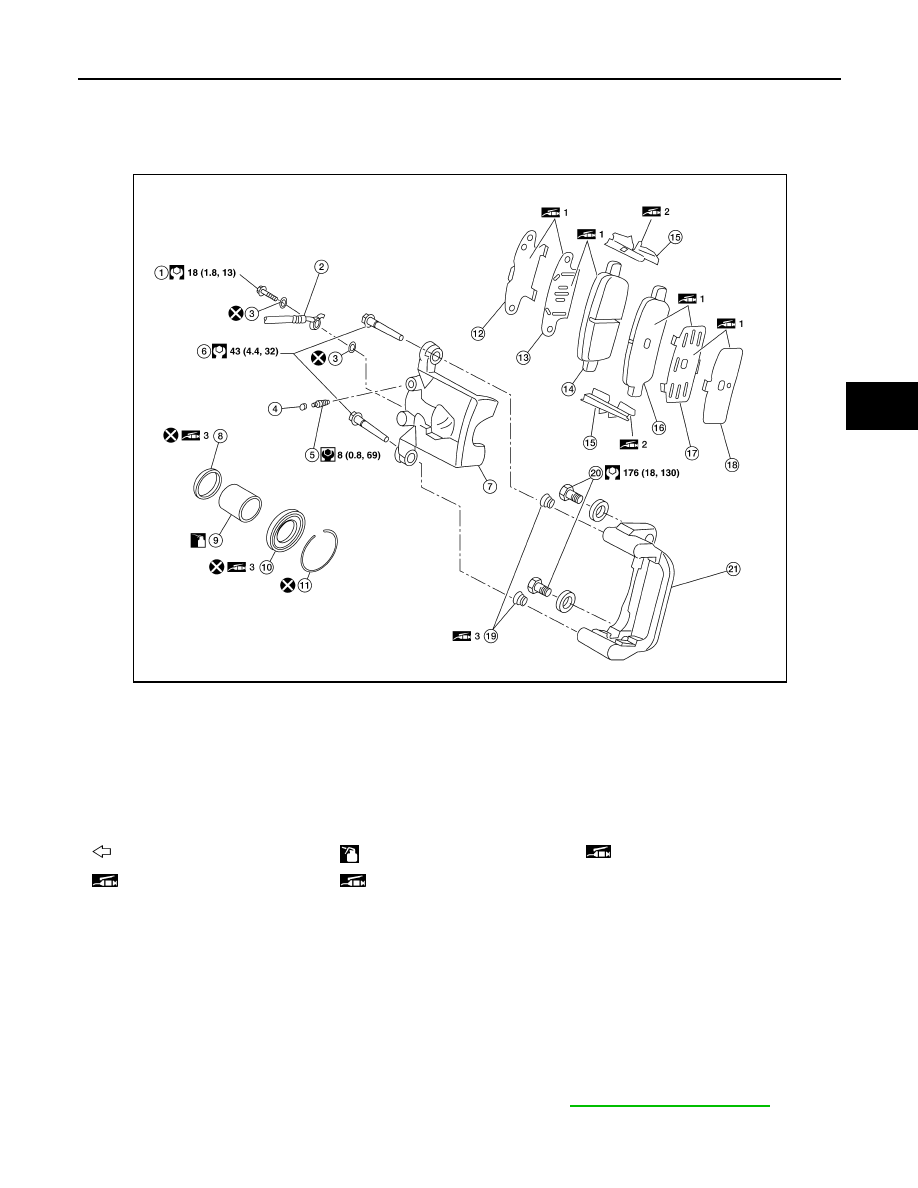

REAR DISC BRAKE

BR-27

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

REAR DISC BRAKE

Component

INFOID:0000000001724666

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

CAUTION:

• While removing cylinder body, never depress the brake pedal because the piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of the cylinder body. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

• Do not damage piston boot.

• Always replace shims and shim covers as a set when replacing brake pads.

• Keep the rotor clean of brake fluid.

• Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads

or linings, or if a soft pedal occurs at very low mileage. Refer to

1.

Connecting bolt

2.

Brake hose

3.

Copper washer

4.

Cap

5.

Air bleeder

6.

Sliding pin

7.

Cylinder body

8.

Piston seal

9.

Piston

10.

Piston boot

11.

Retaining ring

12.

Inner shim cover

13.

Inner shim

14. Inner pad

15.

Pad retainer

16.

Outer pad

17. Outer shim

18.

Outer shim cover

19.

Sliding pin boot

20. Torque member bolts

21.

Torque member

: Front

: Brake fluid

1: M-77 grease

2: M7439 grease

3: Rubber grease

AWFIA0085GB