Mitsubishi Outlander XL. Manual - part 713

NOTE:

⦆

When pushing the engine assembly and transaxle assembly,

check that the propeller shaft assembly, front exhaust pipe,

front roll stopper, and center member assembly are already

removed.

INSTALLATION SERVICE POINTS

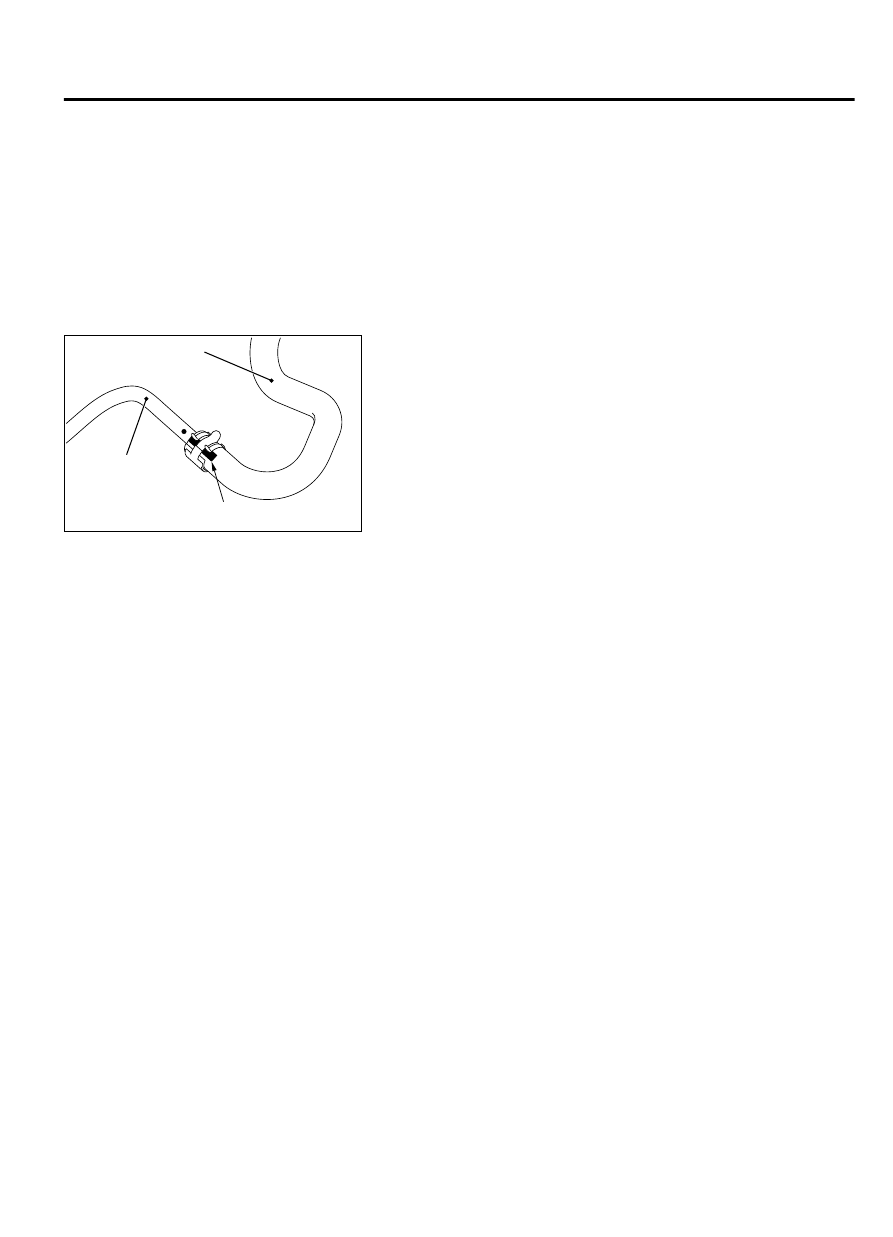

>>A<< RETURN TUBE B/RETURN HOSE C INSTALLATION

ZC5019780000

Marking

Return hose G1

Return tube C

1.

Align the marking as shown in the figure and connect the

return hose G1.

INSPECTION

M13702000058USA0000010000

POWER STEERING OIL PRESSURE SENSOR

CHECK

Refer to GROUP 13Ab - Diagnostic trouble code chart P.

13Ab-44.

NOTE:

The engine ECU diagnoses the power steering oil

pressure sensor and sets the diagnostic trouble code if any

malfunction occurs.

POWER STEERING

37-41

POWER STEERING HOSES