Mitsubishi Outlander XL. Manual - part 695

SPECIAL TOOL

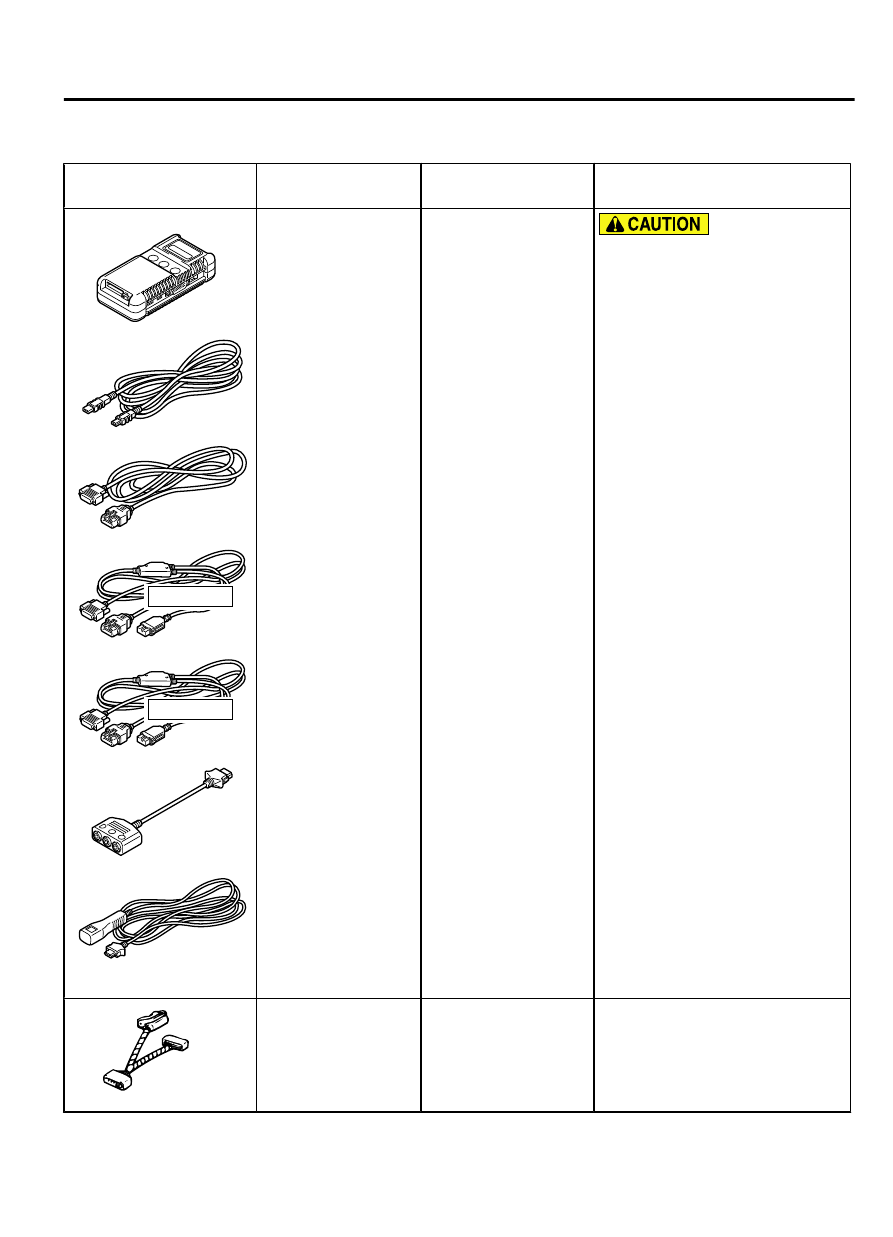

M13506100002USA0000010000

Tool

Tool number and

name

Supersession

Application

MB991910

MB991826

YB9919580000

MB991911

MB991914

MB991824

MB991827

MB991825

Do not use

Do not use

a

b

c

d

e

f

g

MB991958

a.

MB991824

b.

MB991827

c.

MB991910

d.

MB991911

e.

MB991914

f.

MB991825

g.

MB991826

M.U.T.-III

sub

assembly

a.

Vehicle

communication

interface (V.C.I.)

b.

M.U.T.-III

USB

cable

c.

M.U.T.-III

main

harness

A

(Vehicles

with

CAN

communication

system)

d.

M.U.T.-III

main

harness

B

(Vehicles without

CAN

communication

system)

e.

M.U.T.-III

main

harness C (for

Daimler Chrysler

models only)

f.

M.U.T.-III

measurement

adapter

g.

M.U.T.-III trigger

harness

MB991824-KIT

NOTE:

G: MB991826

M.U.T.-III Trigger

Harness is not

necessary when

pushing V.C.I. ENTER

key.

M.U.T.-III main harness A

(MB991910) should be used.

M.U.T.-III main harness B and C

should not be used for this

vehicle.

ASC check (Diagnostic trouble

code display, service data display

and calibration by scan tool )

MB991997

MB991997

ASC check harness

Voltage inspection at ASC-ECU

terminals

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-187

SPECIAL TOOL