Mitsubishi Outlander XL. Manual - part 543

REMOVAL SERVICE POINTS

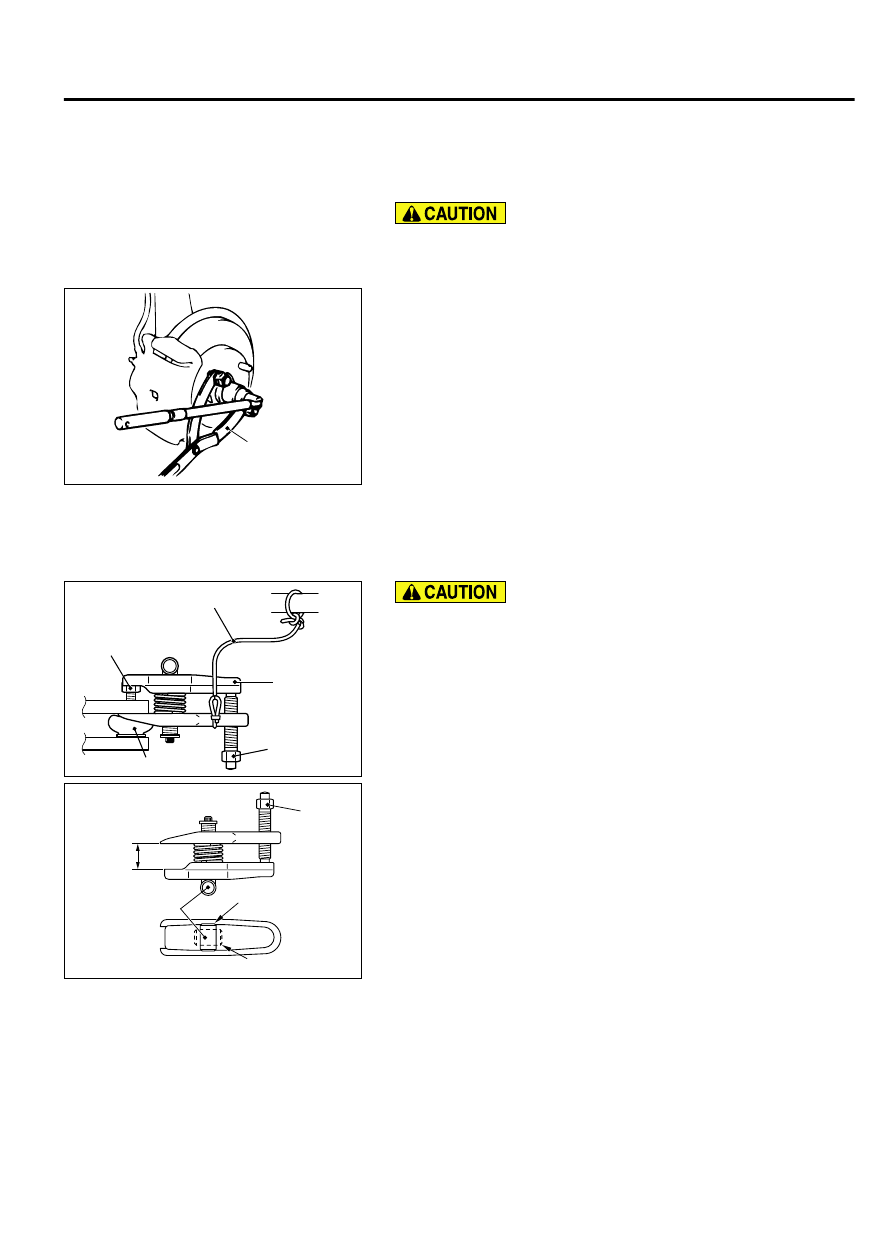

<<A>> DRIVESHAFT NUT REMOVAL

Do not apply the vehicle weight on the wheel bearing with

the driveshaft nut loosened. Otherwise, the wheel bearing

may be broken.

ZC5000630000

MB990767

Use special tool MB990767 to counter the hub as shown in the

figure to remove the driveshaft nut.

<<B>> SELF-LOCKING NUT (TIE-ROD END CONNECTION)

REMOVAL

ZC5018680000

Cord

Bolt

MB991897

or

MB992011

Nut

Ball joint

⦆

Loosen the self-locking nut (tie-rod end connection) from

the ball joint, but do not remove here. Use the special tool.

⦆

To prevent the special tool from dropping off, suspend it

with a rope.

1.

Install special tool MB991897 or MB992011, as shown in the

figure.

ZC5000600000

Parallel

Knob

Bolt

Correct

Wrong

2.

Turn the bolt and knob to make the special tool jaws parallel,

then hand-tighten the bolt. After tightening, check that the jaws

are still parallel.

NOTE:

To adjust the special tool jaws to be parallel, set

the orientation of the knob as shown in the figure.

3.

Unscrew the bolt to disconnect the ball joint.

FRONT AXLE

26-19

DRIVESHAFT ASSEMBLY