Mitsubishi Outlander XL. Manual - part 541

REMOVAL SERVICE POINTS

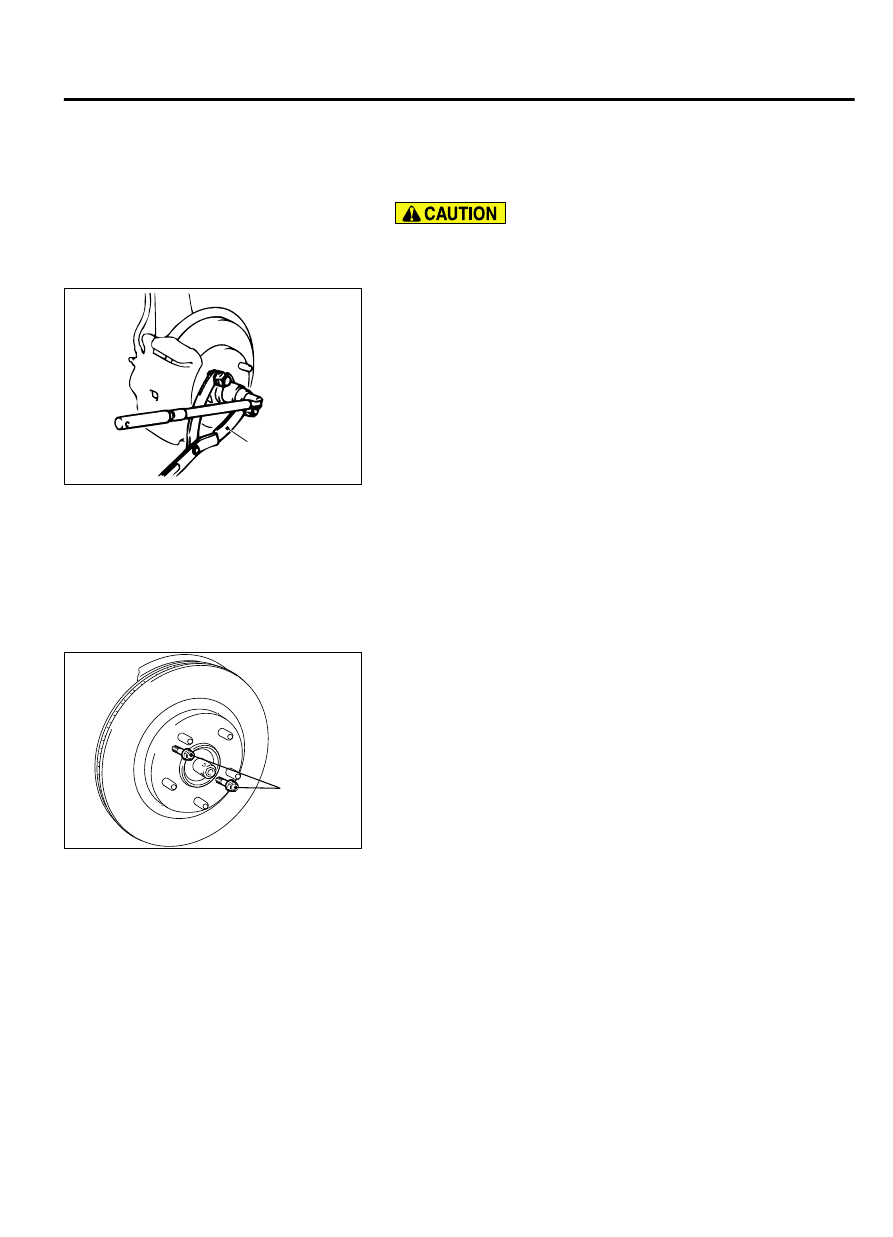

<<A>> DRIVESHAFT NUT REMOVAL

Do not apply the vehicle weight on the front wheel hub

assembly with the driveshaft nut loosened. Otherwise, the

wheel bearing may be broken.

ZC5000630000

MB990767

Use special tool MB990767 to counter the hub as shown in the

figure to remove the driveshaft nut.

<<B>> CALIPER ASSEMBLY REMOVAL

Secure the removed caliper assembly with wire, etc.

<<C>> BRAKE DISC REMOVAL

ZC5018610000

Bolts

(M8 × 1.25)

If the brake disc removal is difficult, install bolts (M8 x 1.25 mm)

shown in the figure, and tighten them evenly and gradually to

remove the brake disc.

FRONT AXLE

26-11

FRONT AXLE HUB ASSEMBLY