Mitsubishi Outlander XL. Manual - part 500

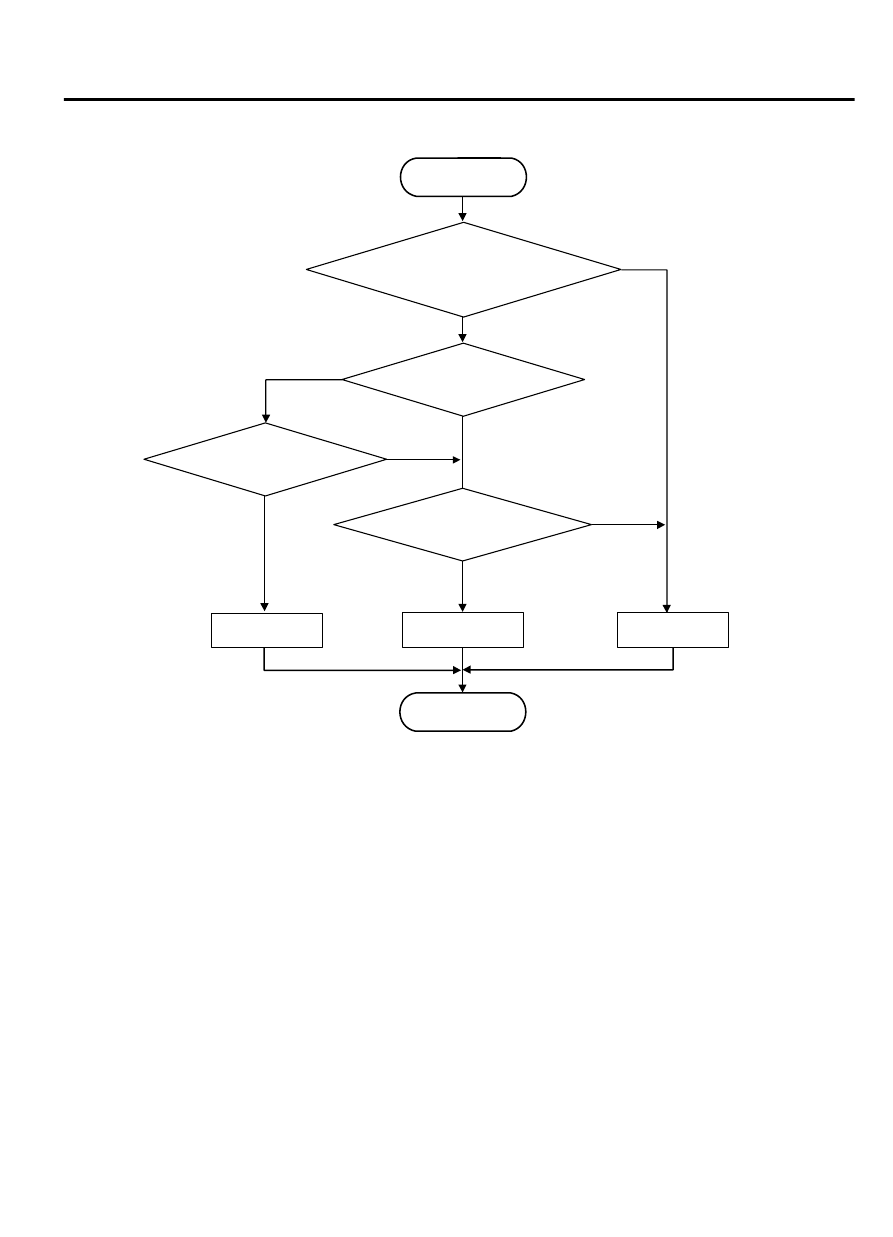

LOGIC FLOW CHARTS (Monitor Sequence)

ZC604085

Continuous failure

for 200 msecs.

Good

Malfunction

END

START

No

No

Good

No

Yes

Yes

Yes

No

Yes

Short to ground

Open judgement

Ignition switch :ON

(Battery positive voltage

≧

2V)

0000

DTC SET CONDITIONS

Check Conditions <Circuit continuity ground>

⦆

Voltage of battery: 2 volts or more.

Judgement Criteria <Circuit continuity ground>

⦆

Ground short judgement: abnormal. (0.2 second)

Check Conditions <Circuit continuity open>

⦆

Voltage of battery: 2 volts or more.

⦆

Ground short judgement: normal.

Judgement Criteria <Circuit continuity open>

⦆

Open judgement: abnormal. (0.2 second)

OBD-II DRIVE CYCLE PATTERN

Start the engine, and keep the vehicle stopped in "P"

range for 5 seconds.

TROUBLESHOOTING HINTS (THE MOST LIKELY

CAUSES FOR THIS CODE TO BE SET ARE:)

⦆

Malfunction of the low-reverse brake shift solenoid

valve system circuit

⦆

Damaged harness or connector

⦆

Malfunction of the TCM

⦆

Malfunction of the low-reverse brake shift solenoid

valve (valve body assembly)

AUTOMATIC TRANSAXLE MECHANICAL

23A-115

AUTOMATIC TRANSAXLE DIAGNOSIS