Mitsubishi Outlander XL. Manual - part 470

NOTE:

If the operation sound is not heard, and the circuit

is normal, either the stepper motor or the ECM or PCM may

have failed.

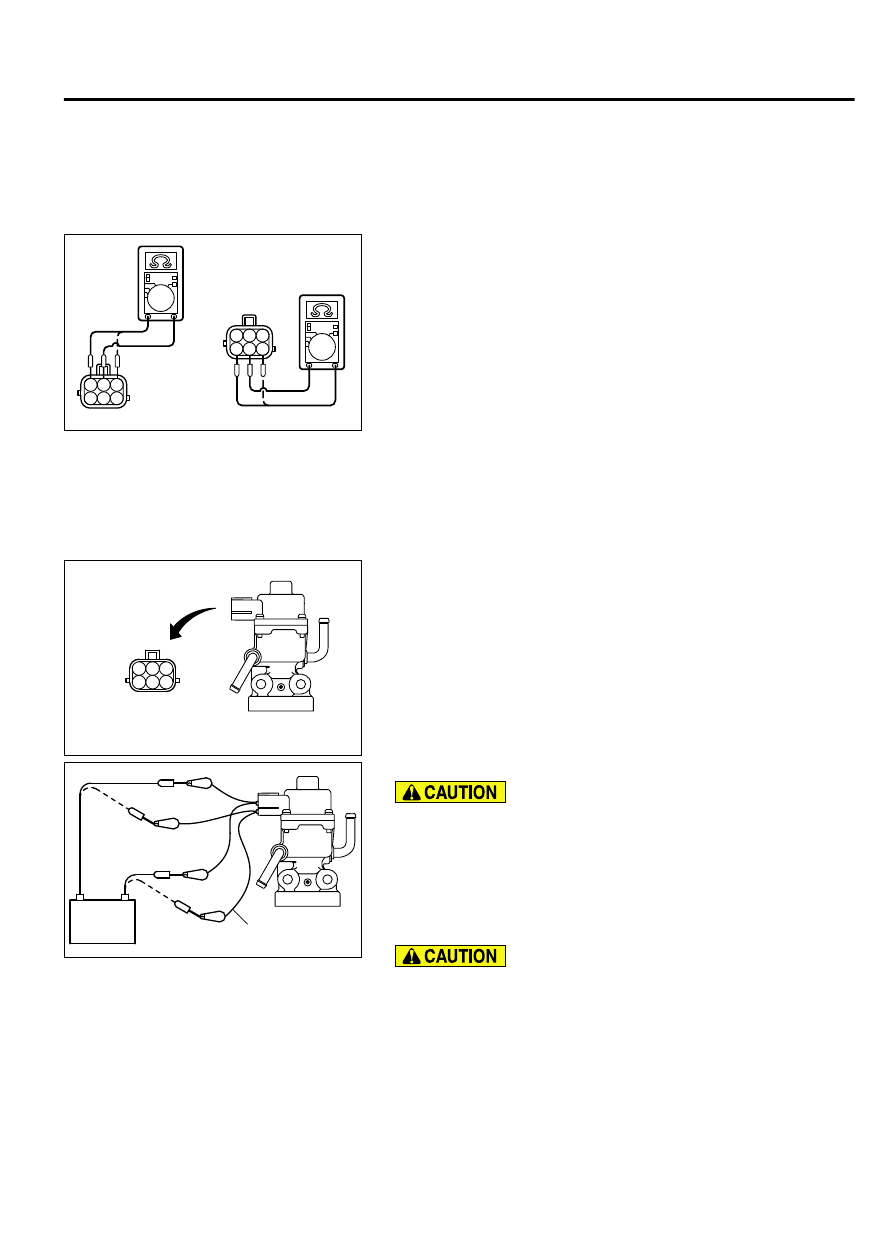

Checking the Coil Resistance

ZK600385

1 2 3

4 5 6

1 2 3

4 5 6

AA00

1.

Remove the EGR valve.

2.

Measure the resistance between terminal No. 2 and either

terminal No. 1 or terminal No. 3 of the connector at the EGR

valve.

Standard value: 20 - 24 Ω [at 20°C (68°F)]

3.

If the resistance is not within the standard, replace the EGR

valve.

4.

Measure the resistance between terminal No. 5 and either

terminal No. 6 or terminal No. 4 of the connector at the EGR

valve.

Standard value: 20 - 24 Ω [at 20°C (68°F)]

5.

If the resistance is not within the standard, replace the EGR

valve.

Operation Check

1.

Remove the EGR valve.

ZK600386

1 2 3

4 5 6

AA00

EGR valve

2.

Connect special tool MB991658 to the EGR valve.

ZK600387

MB991658

Battery

AA00

3.

Connect the battery positive (+) terminal to terminal No. 2.

Connecting battery voltage to the EGR valve for a long time

could damage the coil.

4.

Connect terminals 1 and 3 to the negative (-) terminal of the

battery, in order to test whether the stepper motor vibrates

(with a slight shudder), indicating that the stepper motor is

operating.

5.

Connect the battery positive (+) terminal to terminal No. 5.

Connecting battery voltage to the EGR valve for a long time

could damage the coil.

6.

Connect terminals 4 and 6 to the negative (-) terminal of the

battery, in order to test whether the stepper motor vibrates

(with a slight shudder), indicating that the stepper motor is

operating.

EMISSION CONTROL <MFI>

17c-15

EXHAUST GAS RECIRCULATION (EGR) SYSTEM