Mitsubishi Outlander XL. Manual - part 392

ZK603186AA00

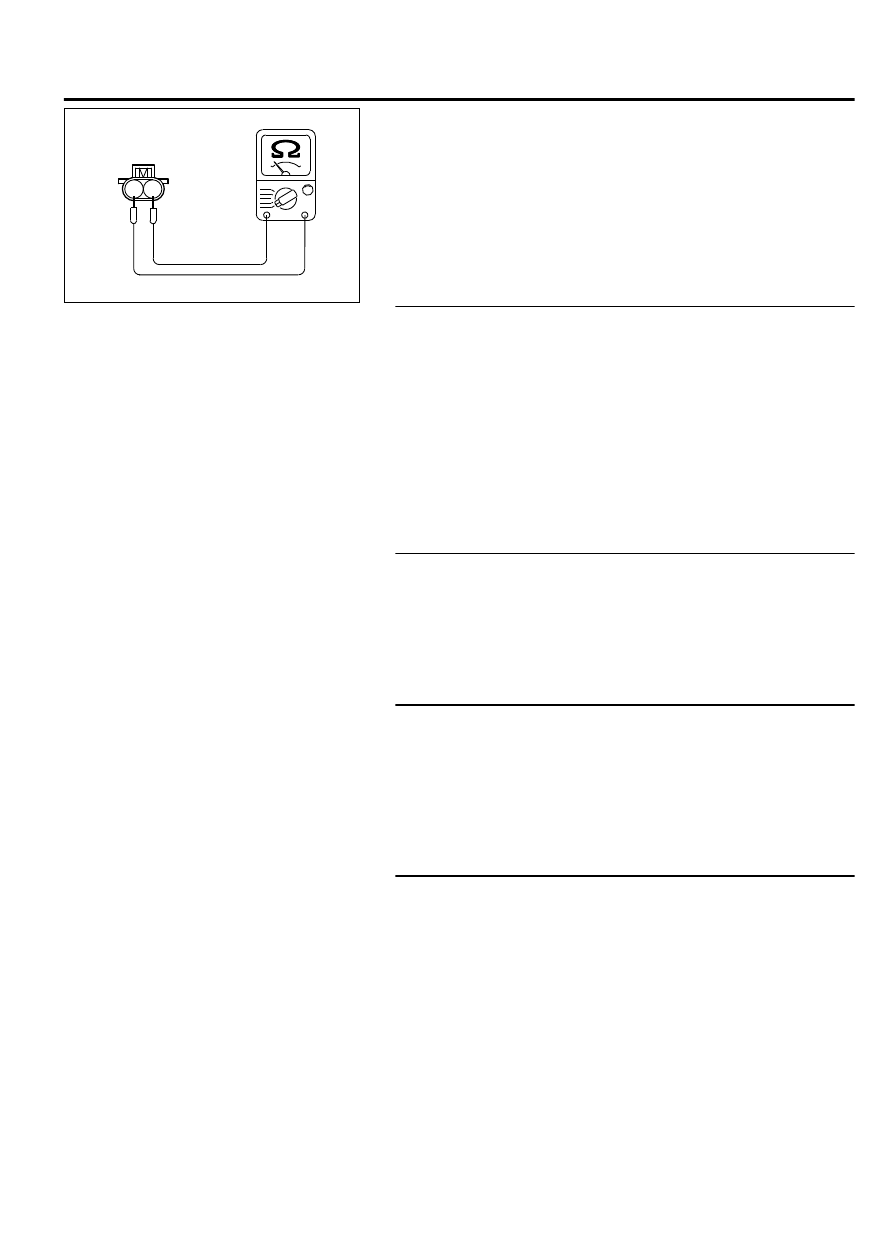

Injector side

connector

1 2

(3)

Measure the resistance between injector side connector

terminal No. 1 and No. 2.

Standard value: 10.5 - 13.5 Ω [at 20 °C (68°F)]

Q:Is the measured resistance between 10.5 and 13.5 ohms

[at 20°C (68°F)]?

YES:

Go to Step 13.

NO:

Replace the injector. Then confirm that the

malfunction symptom is eliminated.

STEP 13. Check harness connector B-101, B-103, B-104 at

right bank injector for damage.

(1)

Check the injector connector, which deviates from the

standard value at Step 11.

Q:Is the harness connector in good condition?

YES:

Repair harness wire between injector intermediate

connector and right bank injector connector because of

harness damage. Then confirm that the malfunction symptom

is eliminated.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then confirm that the

malfunction symptom is eliminated.

STEP 14. Check harness connector B-21 at intermediate

connector for damage.

Q:Is the harness connector in good condition?

YES:

Go to Step 15.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then confirm that the

malfunction symptom is eliminated.

STEP 15. Check harness connector B-10 at ECM and

harness connector B-115, B-116, B-120 at left bank injector

for damage.

Q:Is the harness connector in good condition?

YES:

Go to Step 16.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then confirm that the

malfunction symptom is eliminated.

STEP 16. Check for harness damage between injector

connector and ECM connector.

(1)

Disconnect the injector connector and ECM connector.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-763

SYMPTOM PROCEDURES