Mitsubishi Outlander XL. Manual - part 372

ZK603194

82 81 80 79 78 77 76 75 74 73 72 71

94 93 92 91 90 89 88 87 86 85 84 83

99 98 97 96 95

100

101

102

103

104

105

106

112

113

114

109 108

107

110

111

115

116

117

118

AA00

Special tool 48-pin

connector:

component side

(2)

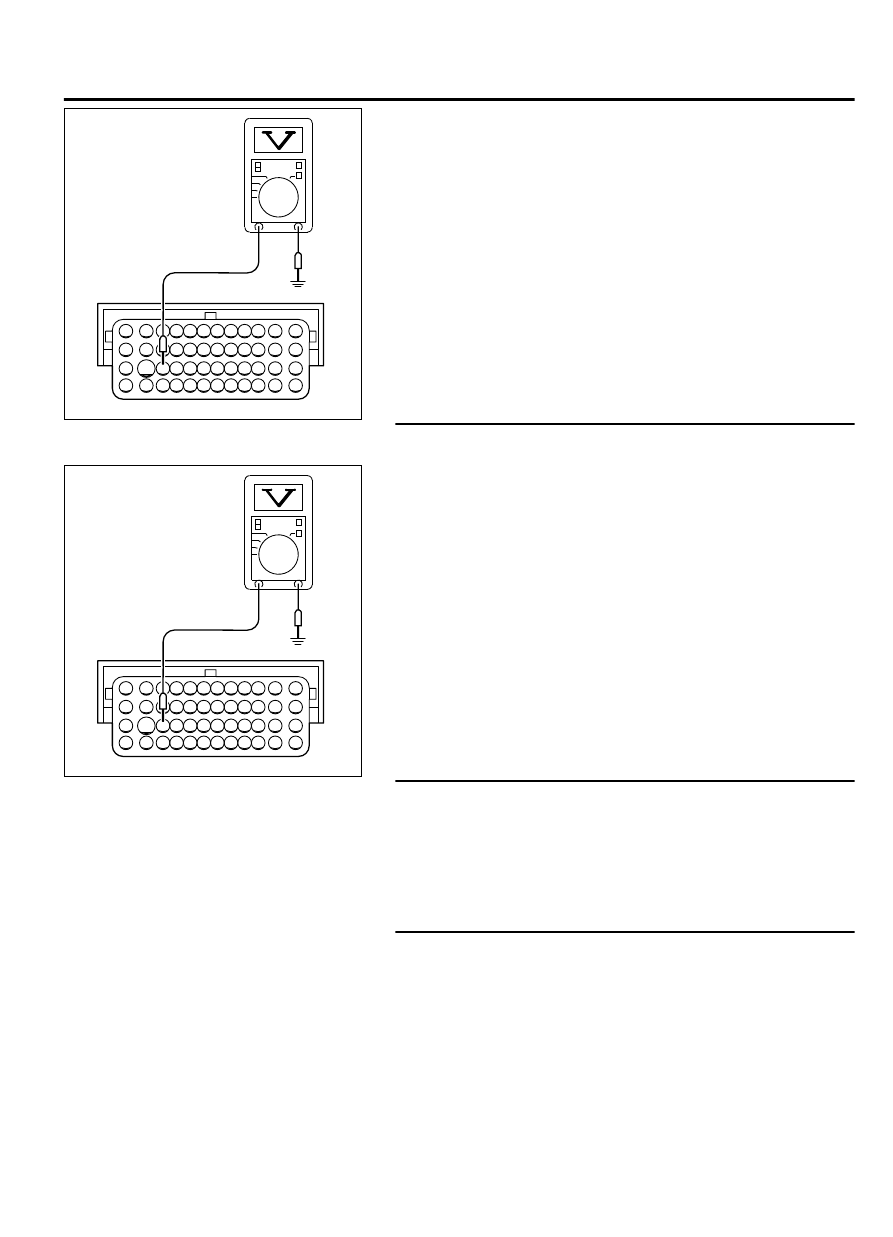

Measure the voltage between terminal No. 104 and ground.

⦆

Voltage should be battery positive voltage.

Q:Is battery positive voltage (approximately 12 volts)

present?

YES:

Go to Step 5.

NO:

Go to Step 3.

STEP 3. Measure the backup power supply voltage at ECM

harness side connector B-11.

ZK603194

82 81 80 79 78 77 76 75 74 73 72 71

94 93 92 91 90 89 88 87 86 85 84 83

99 98 97 96 95

100

101

102

103

104

105

106

112

113

114

109 108

107

110

111

115

116

117

118

AA00

Special tool 48-pin

connector:

component side

(1)

Disconnect the ECM connector B-11 and measure at the

harness side.

(2)

Measure the voltage between terminal No. 104 and ground.

⦆

Voltage should be battery positive voltage.

Q:Is battery positive voltage (approximately 12 volts)

present?

YES:

Go to Step 4.

NO:

Repair harness wire between battery and ECM connector

B-11 (terminal No. 104) because of open circuit or short

circuit to ground. Then go to Step 6.

STEP 4. Check harness connector B-11 at ECM for damage.

Q:Is the harness connector in good condition?

YES:

Repair harness wire between battery and ECM

connector B-11 (terminal No. 104) because of harness

damage. Then go to Step 6.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then go to Step 6.

STEP 5. Check harness connector B-11 at ECM for damage.

Q:Is the harness connector in good condition?

YES:

Replace the ECM. When the ECM is replaced, register

the ID code. Refer to GROUP 42B, ID Code Registration

Judgment Table <Vehicles with KOS> P.42B-12or GROUP

42C, ID Code Registration Judgment Table <Vehicles with

WCM> P.42C-8. Then go to Step 6.

NO:

Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection P.00E-2. Then go to Step 6.

MULTIPORT INJECTION SYSTEM (MFI) <DIAGNOSIS>

13Ab-683

DIAGNOSTIC TROUBLE CODE PROCEDURES