Mitsubishi Outlander XL. Manual - part 183

ZK500354AA00

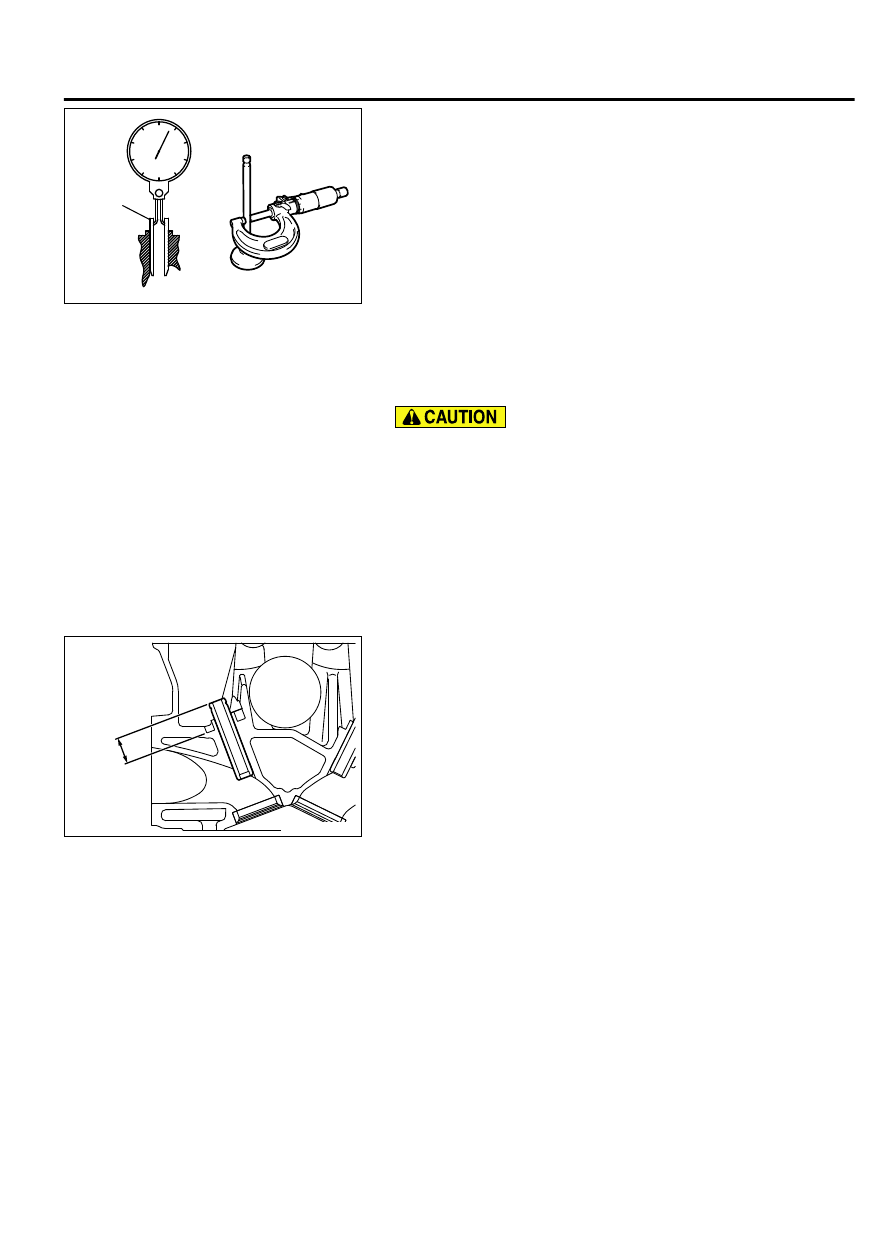

Guide inside diameter

Stem diameter

Valve

guide

Measure the clearance between the valve guide and valve stem.

If it exceeds the limit, replace the valve guide or valve, or both.

Standard value:

Intake 0.020 - 0.047 mm (0.0008 - 0.0018 inch)

Exhaust 0.035 - 0.062 mm (0.0014 - 0.0024 inch)

Limit:

Intake 0.10 mm (0.003 inch)

Exhaust 0.15 mm (0.005 inch)

VALVE GUIDE REPLACEMENT PROCEDURE

1.

Using a press, remove the valve guide toward the cylinder

block.

Do not install a valve guide of the same size again.

2.

Rebore the valve guide hole of the cylinder head so that it fits

the press-fitted oversize valve guide.

Valve guide hole diameters

0.05 oversize: 11.050 - 11.068 mm (0.4351 - 0.4357

inch)

0.25 oversize: 11.250 - 11.268 mm (0.4430 - 0.4436

inch)

0.50 oversize: 11.500 - 11.518 mm (0.4528 - 0.4535

inch)

ZK602123 0000

Protrusion

3.

Press-fit the valve guide until it projects by the specified

amount.

Protrusion: 16.7 - 17.3 mm (0.66 - 0.68 inch)

NOTE:

When press-fitting the valve guide, work from the

cylinder head top surface.

NOTE:

Pay attention to the difference in length of the

valve guides. [Intake side: 45.5 mm (1.79 inches);

exhaust side: 52.5 mm (2.07 inches)]

NOTE:

After installing the valve guides, insert new

valves in them to check for smooth operation.

VALVE SEAT INSPECTION

M11103000909USA0000010000

ENGINE OVERHAUL

11B-51

CYLINDER HEAD AND VALVES