Content .. 1176 1177 1178 1179 ..

Mitsubishi Outlander XL. Manual - part 1178

GENERAL DESCRIPTION

M15502000001USA0000010000

The blower, heater, and evaporator have been

integrated with the heater and A/C system to achieve

greater fan power and noise reduction.

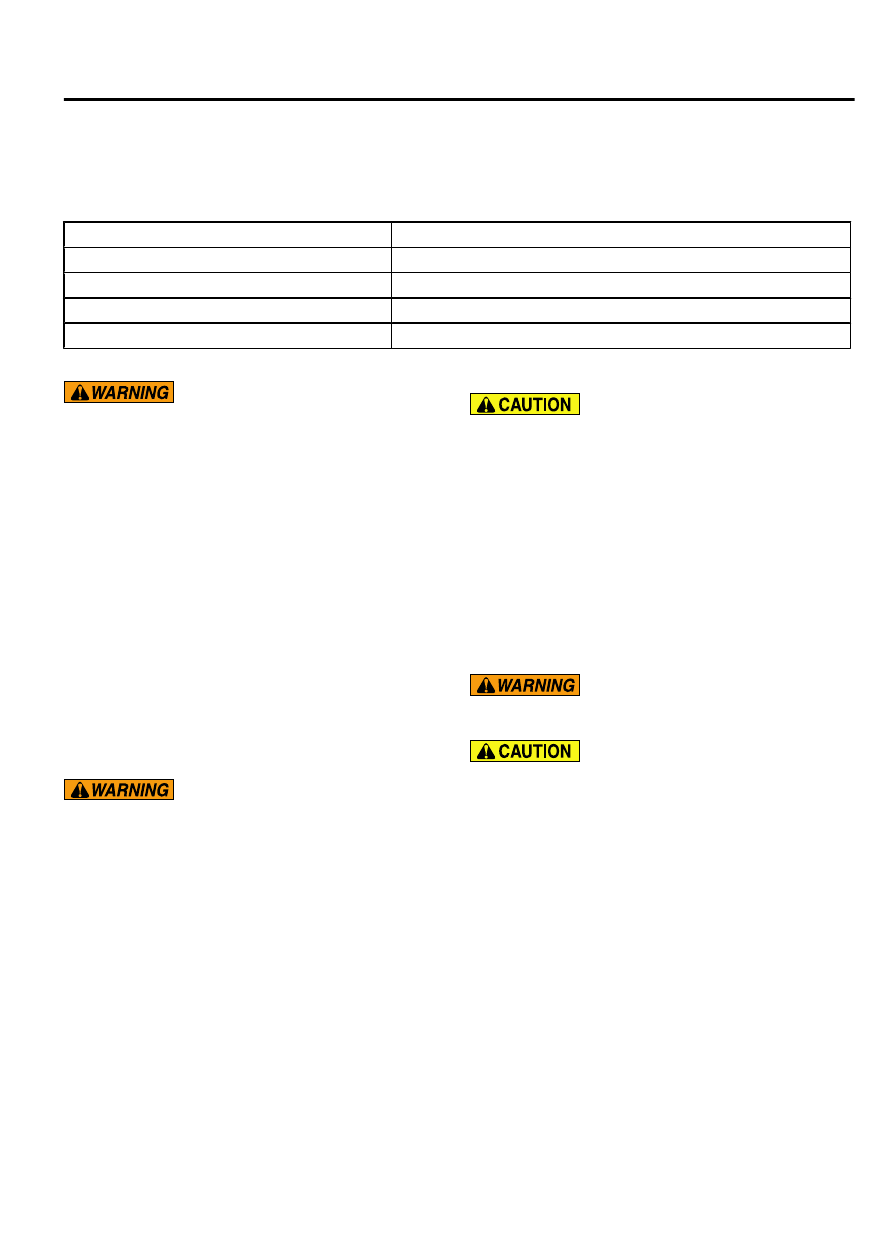

Item

Specification

Heater control assembly

Dial type

Compressor

MSC90CAS

Compressor model

Scroll type

Refrigerant and quantity g (oz)

R-134a (HFC-134a), 480 - 520 (16.9 - 18.3)

SAFETY PRECAUTIONS

Wear safety goggles and gloves when servicing

the refrigeration system to prevent severe

damage to eyes and hands.

Because R-134a refrigerant is a hydro fluorocarbon

(HFC) which contains hydrogen atoms in place of

chlorine atoms, it will not cause damage to the ozone

layer.

Ozone filters out harmful radiation from the sun. To

assist in protecting the ozone layer, Mitsubishi Motors

Corporation recommends an R-134a refrigerant

recycling device.

Refrigerant R-134a is transparent and colorless in

both the liquid and vapor state. Since it has a boiling

point of -29.8°C (-21.64°F) at atmospheric pressure,

it will be a vapor at all normal temperatures and

pressures. The vapor is heavier than air, non-

flammable, and non-explosive. The following

precautions must be observed when handling

R-134a.

Do not heat R-134a above 40°C (104.0°F) or it may

catch fire and explode.

R-134a evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigeration

part of the A/C system. Keep a bottle of sterile mineral

oil handy when working on the refrigeration system.

1.

Should any liquid refrigerant get into your eyes, use

a few drops of mineral oil to wash them out. R-134a

is rapidly absorbed by the oil.

2.

Next, splash your eyes with plenty of cold water.

3.

Call your doctor immediately even if irritation has

ceased.

Keep R-134a containers upright when charging

the system.

In most instances, moderate heat is required to bring

the pressure of the refrigerant in its container above

the pressure of the system when charging or adding

refrigerant.

A bucket or large pan of hot water not over 40°C

(104.0°F) is all the heat required for this purpose. Do

not heat the refrigerant container with a blow torch or

any other means that would raise temperature and

pressure above this temperature. Do not weld or

steam-clean on or near the system components or

refrigerant lines.

The leak detector for R-134a should be used to

check for refrigerant gas leaks.

Do not allow liquid refrigerant to touch bright

metal or it will be stained.

When metering R-134a into the refrigeration system,

keep the supply tank or cans in an upright position. If

the refrigerant container is on its side or upside down,

liquid refrigerant will enter the system and damage the

compressor.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

AIR CONDITIONING

55A-3

GENERAL DESCRIPTION